What is Global Copper Sinter Paste Market?

The Global Copper Sinter Paste Market is a specialized segment within the broader materials industry, focusing on the production and application of copper-based sinter pastes. These pastes are primarily used in high-temperature applications due to their excellent thermal and electrical conductivity. Copper sinter paste is a critical component in various industries, including electronics, automotive, and renewable energy, where it serves as a bonding agent for components that require robust thermal management and electrical connectivity. The market is driven by the increasing demand for miniaturized and efficient electronic devices, which necessitate advanced materials capable of withstanding high operational temperatures. Additionally, the push towards renewable energy sources has spurred the need for efficient photovoltaic systems, further boosting the demand for copper sinter paste. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the performance characteristics of copper sinter pastes to meet the evolving needs of end-users. As industries continue to advance technologically, the role of copper sinter paste becomes increasingly vital, making it a key area of interest for researchers and manufacturers alike. The market's growth is also supported by the rising trend of electric vehicles, which require efficient thermal management solutions.

Epoxy Reinforced Type, Regular type in the Global Copper Sinter Paste Market:

In the Global Copper Sinter Paste Market, two prominent types of pastes are widely recognized: Epoxy Reinforced Type and Regular Type. The Epoxy Reinforced Type is a specialized variant that incorporates epoxy resins to enhance the mechanical properties of the paste. This type is particularly favored in applications where additional strength and durability are required, such as in high-stress environments or where the paste must endure significant mechanical loads. The epoxy component acts as a binder, providing improved adhesion and resistance to thermal cycling, which is crucial in maintaining the integrity of electronic assemblies over time. This type of paste is often used in advanced electronic applications, where reliability and longevity are paramount. On the other hand, the Regular Type of copper sinter paste is more commonly used in standard applications where the primary requirements are good thermal and electrical conductivity without the need for additional mechanical reinforcement. This type is typically easier to apply and cure, making it suitable for mass production processes where efficiency and cost-effectiveness are key considerations. The Regular Type is often employed in applications such as general-purpose electronic assemblies, where the operational conditions are less demanding. Both types of copper sinter paste play a crucial role in the market, catering to different needs and applications. The choice between Epoxy Reinforced and Regular Type depends largely on the specific requirements of the application, including factors such as operating temperature, mechanical stress, and environmental conditions. As the market continues to evolve, manufacturers are investing in research and development to further enhance the properties of both types of pastes, aiming to expand their applicability and improve performance. This ongoing innovation is essential to meet the growing demands of industries such as electronics, automotive, and renewable energy, where the need for reliable and efficient materials is ever-increasing. The development of new formulations and the refinement of existing ones are key strategies employed by manufacturers to maintain a competitive edge in the market. Additionally, the trend towards miniaturization and increased functionality in electronic devices is driving the demand for more advanced copper sinter pastes that can deliver superior performance in smaller, more compact assemblies. This has led to a focus on improving the thermal and electrical conductivity of the pastes, as well as their ability to withstand harsh operating conditions. The Global Copper Sinter Paste Market is thus characterized by a dynamic interplay between technological advancement and market demand, with manufacturers striving to develop products that meet the evolving needs of their customers. As industries continue to push the boundaries of what is possible, the role of copper sinter paste as a critical material in high-performance applications is set to grow even further.

Electronics and Semiconductors, Photovoltaics, Automotive, Other in the Global Copper Sinter Paste Market:

The usage of Global Copper Sinter Paste Market spans several key areas, including Electronics and Semiconductors, Photovoltaics, Automotive, and other industries. In the Electronics and Semiconductors sector, copper sinter paste is used extensively for its excellent thermal and electrical conductivity. It serves as a critical bonding agent in the assembly of electronic components, ensuring reliable connections and efficient heat dissipation. This is particularly important in high-performance devices where thermal management is crucial to prevent overheating and ensure longevity. The paste's ability to withstand high temperatures makes it ideal for use in power electronics and semiconductor devices, where it helps to enhance performance and reliability. In the Photovoltaics industry, copper sinter paste is used in the production of solar cells, where it plays a vital role in improving the efficiency of energy conversion. The paste is used to form electrical connections between the cells, ensuring optimal conductivity and minimizing energy loss. This is essential for maximizing the output of photovoltaic systems and making solar energy a more viable and sustainable option. In the Automotive sector, copper sinter paste is used in the manufacturing of various components, including sensors, control units, and power modules. Its excellent thermal properties make it ideal for use in electric vehicles, where efficient heat management is critical to ensure the performance and safety of the vehicle. The paste is also used in traditional internal combustion engine vehicles, where it helps to improve the efficiency and reliability of electronic systems. Beyond these key areas, copper sinter paste is also used in other industries, such as telecommunications and aerospace, where its unique properties are leveraged to enhance the performance and reliability of critical components. In telecommunications, for example, the paste is used in the assembly of high-frequency devices, where it helps to ensure stable and reliable connections. In aerospace, the paste is used in the manufacturing of components that require high thermal and electrical conductivity, such as sensors and control systems. The versatility and performance of copper sinter paste make it an essential material in a wide range of applications, driving its demand across various industries. As technology continues to advance and the need for efficient and reliable materials grows, the role of copper sinter paste in these key areas is set to become even more significant.

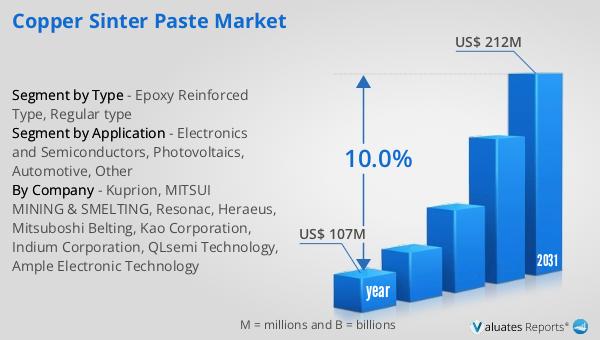

Global Copper Sinter Paste Market Outlook:

The global market for Copper Sinter Paste was valued at approximately 107 million US dollars in 2024. It is anticipated to expand significantly, reaching an estimated size of 212 million US dollars by the year 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 10.0% over the forecast period. The market's expansion is driven by the increasing demand for high-performance materials in various industries, including electronics, automotive, and renewable energy. As these industries continue to evolve and innovate, the need for materials that can deliver superior thermal and electrical conductivity becomes more critical. Copper sinter paste, with its unique properties, is well-positioned to meet these demands, making it a key material in the development of advanced technologies. The projected growth of the market underscores the importance of copper sinter paste in enabling the next generation of electronic devices, automotive components, and renewable energy systems. As manufacturers continue to invest in research and development to enhance the performance characteristics of copper sinter paste, the market is expected to witness sustained growth, driven by the increasing adoption of this versatile material across various applications. The market's positive outlook is a testament to the growing recognition of copper sinter paste as an essential component in the advancement of technology and the pursuit of more efficient and sustainable solutions.

| Report Metric | Details |

| Report Name | Copper Sinter Paste Market |

| Accounted market size in year | US$ 107 million |

| Forecasted market size in 2031 | US$ 212 million |

| CAGR | 10.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kuprion, MITSUI MINING & SMELTING, Resonac, Heraeus, Mitsuboshi Belting, Kao Corporation, Indium Corporation, QLsemi Technology, Ample Electronic Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |