What is Global Radiation Hardness Testing Market?

The Global Radiation Hardness Testing Market is a specialized sector focused on evaluating the resilience of electronic components and systems against radiation. This market is crucial for industries where equipment is exposed to high levels of radiation, such as aerospace, nuclear, and military applications. Radiation hardness testing ensures that electronic devices can withstand harsh environments without malfunctioning. The testing process involves subjecting components to controlled radiation levels to assess their durability and performance. This market is driven by the increasing demand for reliable and robust electronic systems in critical applications. As technology advances, the need for radiation-hardened components grows, making this market an essential part of the supply chain for industries operating in extreme conditions. The market encompasses various testing methods and services, catering to the specific needs of different sectors.

Total Ionizing Dose (TID) Test, Single Event Effects (SEE) Test, Displacement Damage Test in the Global Radiation Hardness Testing Market:

Total Ionizing Dose (TID) Test, Single Event Effects (SEE) Test, and Displacement Damage Test are critical components of the Global Radiation Hardness Testing Market. The TID Test measures the cumulative radiation dose absorbed by a material or device over time. This test is essential for understanding how prolonged exposure to radiation affects electronic components, particularly in environments like space where radiation levels are consistently high. The TID Test helps in determining the lifespan and reliability of electronic systems by simulating long-term radiation exposure. On the other hand, the Single Event Effects (SEE) Test focuses on the impact of a single, high-energy particle striking a device. This test is crucial for identifying vulnerabilities in electronic components that could lead to sudden malfunctions or failures. SEE testing is particularly important for aerospace and military applications, where a single event can have catastrophic consequences. The Displacement Damage Test evaluates the structural damage caused by radiation at the atomic level. This test is vital for understanding how radiation affects the physical properties of materials, which can lead to changes in electrical performance. Displacement damage is a concern in environments with high neutron or proton radiation, such as nuclear reactors or space missions. Each of these tests plays a significant role in ensuring that electronic components can withstand the specific types of radiation they will encounter in their operational environments. The Global Radiation Hardness Testing Market provides these testing services to help manufacturers design and produce radiation-hardened components that meet the stringent requirements of their respective industries. By conducting these tests, companies can ensure the reliability and safety of their products, ultimately protecting investments and lives in critical applications.

Aerospace, Nuclear Industry, Military and Defense in the Global Radiation Hardness Testing Market:

The Global Radiation Hardness Testing Market plays a pivotal role in several key industries, including aerospace, nuclear, and military and defense. In the aerospace sector, radiation hardness testing is essential for ensuring the reliability of satellites, spacecraft, and other equipment exposed to the harsh conditions of space. Space missions require components that can withstand high levels of radiation without degrading, as failures can lead to mission-critical consequences. Radiation hardness testing helps aerospace companies design and manufacture components that meet the rigorous demands of space exploration. In the nuclear industry, radiation hardness testing is crucial for evaluating the durability of electronic systems used in nuclear power plants and other facilities. These systems must operate reliably in environments with high radiation levels to ensure the safety and efficiency of nuclear operations. Testing helps identify potential vulnerabilities and improve the resilience of electronic components used in nuclear applications. In the military and defense sector, radiation hardness testing is vital for developing robust electronic systems that can withstand the extreme conditions of warfare. Military equipment, such as communication systems, radar, and navigation devices, must remain operational in environments with high radiation levels, such as those encountered during nuclear or electromagnetic pulse (EMP) events. Radiation hardness testing ensures that these systems can continue to function effectively, providing a strategic advantage in defense operations. Overall, the Global Radiation Hardness Testing Market supports these industries by providing the necessary testing services to develop and maintain reliable, radiation-hardened components.

Global Radiation Hardness Testing Market Outlook:

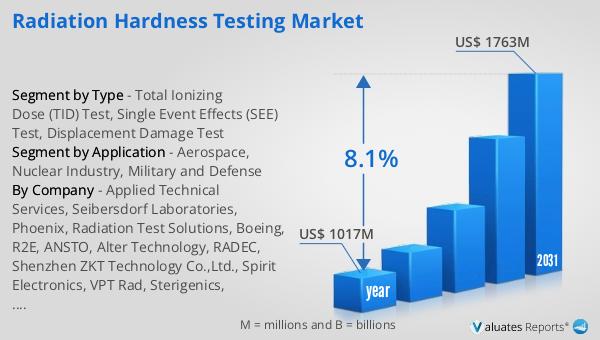

The worldwide market for Radiation Hardness Testing was estimated to be worth $1,017 million in 2024. It is anticipated to expand to a revised valuation of $1,763 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.1% throughout the forecast period. This growth is driven by the increasing demand for radiation-hardened components across various industries, including aerospace, nuclear, and military applications. As these sectors continue to evolve and expand, the need for reliable and robust electronic systems becomes more critical. The Global Radiation Hardness Testing Market is poised to meet this demand by providing essential testing services that ensure the durability and performance of electronic components in high-radiation environments. By investing in radiation hardness testing, companies can enhance the reliability and safety of their products, ultimately protecting investments and lives in critical applications. The market's growth reflects the increasing importance of radiation-hardened components in today's technology-driven world, where electronic systems are integral to the functioning of various industries.

| Report Metric | Details |

| Report Name | Radiation Hardness Testing Market |

| Accounted market size in year | US$ 1017 million |

| Forecasted market size in 2031 | US$ 1763 million |

| CAGR | 8.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Applied Technical Services, Seibersdorf Laboratories, Phoenix, Radiation Test Solutions, Boeing, R2E, ANSTO, Alter Technology, RADEC, Shenzhen ZKT Technology Co.,Ltd., Spirit Electronics, VPT Rad, Sterigenics, Datzmann, NTEK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |