What is Global Composite Copper Foil Electroplating Equipment Market?

The Global Composite Copper Foil Electroplating Equipment Market is a specialized segment within the broader electroplating industry, focusing on the production and enhancement of copper foils through electroplating processes. This market is pivotal for industries that require high-quality copper foils, which are essential components in various electronic devices and energy storage solutions. The equipment used in this market is designed to deposit a thin layer of copper onto a substrate, enhancing its electrical conductivity, durability, and resistance to corrosion. The demand for such equipment is driven by the growing need for efficient and reliable electronic components, particularly in sectors like renewable energy, automotive, and consumer electronics. As technology advances, the market is witnessing innovations aimed at improving the efficiency and precision of electroplating processes, thereby meeting the stringent quality standards required by modern applications. The market's growth is also influenced by the increasing adoption of electric vehicles and renewable energy systems, which rely heavily on high-performance copper foils. Overall, the Global Composite Copper Foil Electroplating Equipment Market plays a crucial role in supporting technological advancements and the transition towards more sustainable energy solutions.

One-step Type, Two-step Type, Others in the Global Composite Copper Foil Electroplating Equipment Market:

In the Global Composite Copper Foil Electroplating Equipment Market, there are different types of equipment designed to cater to specific electroplating needs, namely One-step Type, Two-step Type, and Others. The One-step Type equipment is designed to streamline the electroplating process by combining multiple stages into a single operation. This type of equipment is ideal for applications where time efficiency and simplicity are paramount. It allows manufacturers to reduce production time and costs by eliminating the need for separate processing stages. The One-step Type is particularly beneficial for industries that require high-volume production with consistent quality, such as consumer electronics and automotive sectors. On the other hand, the Two-step Type equipment involves a more segmented approach to electroplating. This type of equipment separates the electroplating process into distinct stages, allowing for greater control and precision over each step. The Two-step Type is often preferred in applications where the quality and customization of the copper foil are critical. It provides manufacturers with the flexibility to adjust parameters at each stage, ensuring that the final product meets specific requirements. This type of equipment is commonly used in industries like aerospace and medical devices, where precision and reliability are of utmost importance. Apart from the One-step and Two-step Types, there are other specialized equipment types that cater to niche applications within the electroplating market. These may include equipment designed for specific substrate materials or those that incorporate advanced technologies for enhanced performance. For instance, some equipment may be tailored for use with flexible substrates, which are increasingly popular in the production of wearable electronics and flexible displays. Others may incorporate advanced monitoring and control systems to ensure optimal plating conditions and minimize defects. The choice of equipment type depends on various factors, including the intended application, production volume, and quality requirements. Manufacturers must carefully evaluate their needs and consider factors such as cost, efficiency, and scalability when selecting the appropriate equipment. As the demand for high-quality copper foils continues to grow, the Global Composite Copper Foil Electroplating Equipment Market is expected to see further innovations and advancements in equipment design and functionality. These developments will likely focus on improving the efficiency, precision, and sustainability of electroplating processes, thereby supporting the evolving needs of industries reliant on copper foils.

New Energy Power Battery, New Energy Storage Battery, Others in the Global Composite Copper Foil Electroplating Equipment Market:

The Global Composite Copper Foil Electroplating Equipment Market finds significant applications in various areas, including New Energy Power Batteries, New Energy Storage Batteries, and others. In the realm of New Energy Power Batteries, copper foils play a crucial role in enhancing the performance and efficiency of batteries used in electric vehicles and renewable energy systems. The electroplating equipment used in this sector is designed to produce high-quality copper foils with excellent electrical conductivity and thermal management properties. These foils are essential for improving the energy density and lifespan of power batteries, thereby supporting the transition towards cleaner and more sustainable energy solutions. In the context of New Energy Storage Batteries, the demand for reliable and efficient energy storage solutions is driving the need for advanced electroplating equipment. Copper foils produced through electroplating processes are used as current collectors in energy storage systems, where they facilitate the efficient transfer of electrical energy. The quality and performance of these foils are critical for ensuring the reliability and longevity of energy storage batteries, which are increasingly being used in applications such as grid stabilization and backup power systems. The Global Composite Copper Foil Electroplating Equipment Market also serves other industries that require high-performance copper foils. These may include sectors like telecommunications, where copper foils are used in the production of printed circuit boards and other electronic components. The equipment used in these applications is designed to meet the stringent quality standards required for high-frequency and high-speed data transmission. Additionally, the market caters to emerging applications such as flexible electronics and wearable devices, where the demand for lightweight and flexible copper foils is on the rise. The versatility and adaptability of electroplating equipment make it an essential tool for manufacturers looking to innovate and meet the evolving needs of various industries. As technology continues to advance, the Global Composite Copper Foil Electroplating Equipment Market is expected to play a pivotal role in supporting the development of next-generation energy solutions and electronic devices.

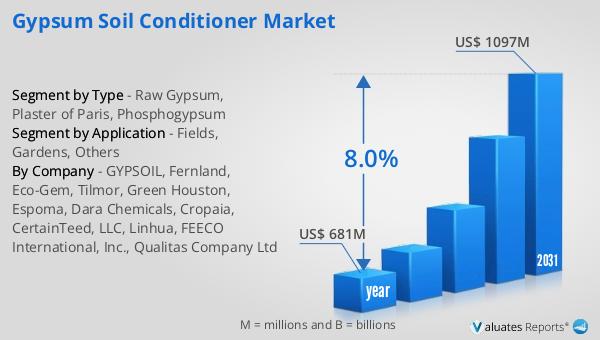

Global Composite Copper Foil Electroplating Equipment Market Outlook:

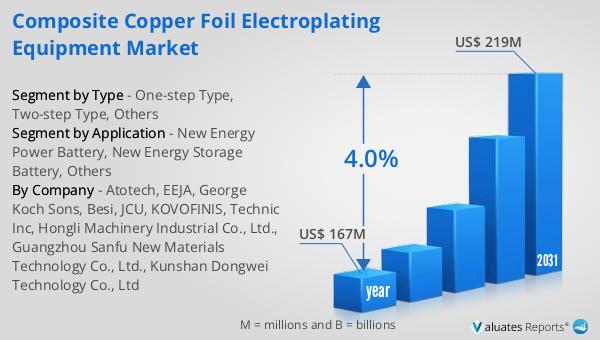

The global market for Composite Copper Foil Electroplating Equipment was valued at $167 million in 2024 and is anticipated to expand to a revised size of $219 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% over the forecast period. This growth trajectory underscores the increasing demand for high-quality copper foils across various industries, driven by advancements in technology and the growing emphasis on sustainable energy solutions. The market's expansion is indicative of the critical role that electroplating equipment plays in enhancing the performance and efficiency of copper foils, which are essential components in a wide range of applications. As industries continue to evolve and adopt more sophisticated technologies, the need for reliable and efficient electroplating equipment is expected to rise. This growth is further supported by the increasing adoption of electric vehicles and renewable energy systems, which rely heavily on high-performance copper foils. The projected growth of the Global Composite Copper Foil Electroplating Equipment Market highlights the importance of innovation and technological advancements in meeting the evolving needs of industries reliant on copper foils. As manufacturers strive to improve the efficiency, precision, and sustainability of electroplating processes, the market is poised to play a crucial role in supporting the transition towards more sustainable energy solutions and the development of next-generation electronic devices.

| Report Metric | Details |

| Report Name | Composite Copper Foil Electroplating Equipment Market |

| Accounted market size in year | US$ 167 million |

| Forecasted market size in 2031 | US$ 219 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Atotech, EEJA, George Koch Sons, Besi, JCU, KOVOFINIS, Technic Inc, Hongli Machinery Industrial Co., Ltd., Guangzhou Sanfu New Materials Technology Co., Ltd., Kunshan Dongwei Technology Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |