What is Global Intelligent High-Speed Mold Changing Systems Market?

The Global Intelligent High-Speed Mold Changing Systems Market is a rapidly evolving sector that focuses on enhancing the efficiency and speed of mold changes in various manufacturing processes. These systems are designed to reduce downtime and increase productivity by enabling quick and seamless transitions between different molds. This is particularly important in industries where time is of the essence, and production lines need to be as efficient as possible. The market encompasses a range of technologies and solutions, including hydraulic, pneumatic, electric, and modular systems, each offering unique benefits and applications. As industries continue to seek ways to optimize their operations and reduce costs, the demand for intelligent high-speed mold changing systems is expected to grow. These systems not only improve operational efficiency but also contribute to better product quality and consistency, making them an essential component in modern manufacturing environments. The market is characterized by continuous innovation and technological advancements, driven by the need for faster, more reliable, and cost-effective solutions. As a result, companies operating in this space are constantly developing new products and features to meet the evolving needs of their customers.

Hydraulic Mold Changing Systems, Pneumatic Mold Changing Systems, Electric Mold Changing Systems, Modular Mold Changing Systems, Others in the Global Intelligent High-Speed Mold Changing Systems Market:

Hydraulic Mold Changing Systems are a cornerstone of the Global Intelligent High-Speed Mold Changing Systems Market. These systems utilize hydraulic power to facilitate the quick and efficient changing of molds, making them ideal for heavy-duty applications where precision and strength are paramount. The hydraulic systems are known for their robustness and ability to handle large and heavy molds with ease. They are widely used in industries such as automotive and aerospace, where the molds are often substantial in size and weight. The hydraulic systems offer high clamping force and stability, ensuring that the molds are securely held in place during the production process. Pneumatic Mold Changing Systems, on the other hand, use compressed air to achieve mold changes. These systems are typically used for lighter molds and are favored for their speed and simplicity. Pneumatic systems are often employed in industries where rapid mold changes are necessary, such as in the production of consumer goods and electronics. They are known for their ease of use and low maintenance requirements, making them a cost-effective solution for many manufacturers. Electric Mold Changing Systems represent a more modern approach, utilizing electric motors and actuators to change molds. These systems are highly precise and energy-efficient, offering significant advantages in terms of control and repeatability. Electric systems are particularly popular in industries where precision is critical, such as in the production of medical devices and high-tech components. They offer the added benefit of being environmentally friendly, as they do not require hydraulic fluids or compressed air. Modular Mold Changing Systems are designed to offer maximum flexibility and adaptability. These systems can be customized to meet the specific needs of different manufacturing processes, allowing for a high degree of versatility. Modular systems are often used in industries where production lines need to be reconfigured frequently, such as in the packaging and food processing sectors. They offer the advantage of being easily expandable and reconfigurable, making them an attractive option for manufacturers looking to future-proof their operations. Other systems in the market include hybrid solutions that combine elements of hydraulic, pneumatic, and electric systems to offer a balanced approach. These hybrid systems are designed to provide the best of all worlds, offering the strength of hydraulic systems, the speed of pneumatic systems, and the precision of electric systems. As the market continues to evolve, manufacturers are increasingly looking for solutions that offer a combination of speed, precision, and flexibility, driving the development of new and innovative mold changing systems.

Injection Molding, Metal Stamping, Die Casting, Rubber Molding, Others in the Global Intelligent High-Speed Mold Changing Systems Market:

The usage of Global Intelligent High-Speed Mold Changing Systems Market spans several key areas, each benefiting from the unique advantages these systems offer. In Injection Molding, these systems are crucial for reducing downtime and increasing production efficiency. Injection molding is a process used to produce a wide range of plastic parts, and the ability to quickly change molds is essential for maintaining high production rates and meeting tight deadlines. Intelligent high-speed mold changing systems enable manufacturers to switch between different molds rapidly, allowing for greater flexibility and responsiveness to market demands. In Metal Stamping, these systems play a vital role in enhancing productivity and reducing lead times. Metal stamping involves the shaping of metal sheets into specific forms, and the ability to change molds quickly is critical for maintaining a smooth production flow. High-speed mold changing systems allow manufacturers to adapt to different production requirements swiftly, ensuring that they can meet customer demands efficiently. Die Casting is another area where these systems are extensively used. Die casting involves the production of metal parts by forcing molten metal into molds, and the ability to change molds quickly is essential for maintaining high production rates. Intelligent high-speed mold changing systems enable manufacturers to switch between different molds with minimal downtime, ensuring that production lines remain efficient and productive. In Rubber Molding, these systems are used to enhance the efficiency of the molding process. Rubber molding involves the shaping of rubber materials into specific forms, and the ability to change molds quickly is crucial for maintaining high production rates. High-speed mold changing systems allow manufacturers to switch between different molds rapidly, ensuring that they can meet customer demands efficiently. Other areas where these systems are used include the production of consumer goods, electronics, and packaging materials. In these industries, the ability to change molds quickly is essential for maintaining high production rates and meeting tight deadlines. Intelligent high-speed mold changing systems enable manufacturers to switch between different molds rapidly, allowing for greater flexibility and responsiveness to market demands. As industries continue to seek ways to optimize their operations and reduce costs, the demand for intelligent high-speed mold changing systems is expected to grow, driving further innovation and development in this market.

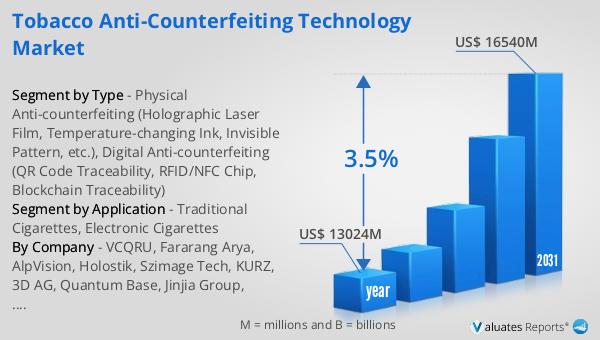

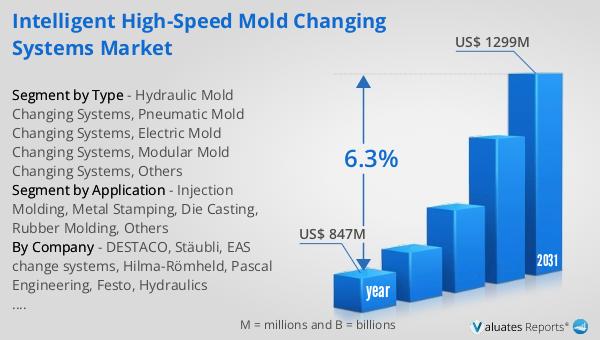

Global Intelligent High-Speed Mold Changing Systems Market Outlook:

The global market for Intelligent High-Speed Mold Changing Systems was valued at $847 million in 2024, and it is anticipated to expand to a revised size of $1,299 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.3% over the forecast period. This upward trajectory underscores the increasing demand for efficient and rapid mold changing solutions across various industries. As manufacturers strive to enhance productivity and reduce downtime, the adoption of intelligent high-speed mold changing systems is becoming more prevalent. These systems offer significant advantages in terms of speed, precision, and flexibility, making them an attractive option for companies looking to optimize their operations. The market's growth is driven by continuous innovation and technological advancements, as companies develop new products and features to meet the evolving needs of their customers. As a result, the global market for intelligent high-speed mold changing systems is poised for significant expansion in the coming years, offering numerous opportunities for growth and development. This growth is indicative of the broader trend towards automation and efficiency in manufacturing, as companies seek to remain competitive in an increasingly globalized market. The increasing adoption of these systems is expected to drive further innovation and development, as manufacturers look for ways to enhance their operations and reduce costs.

| Report Metric | Details |

| Report Name | Intelligent High-Speed Mold Changing Systems Market |

| Accounted market size in year | US$ 847 million |

| Forecasted market size in 2031 | US$ 1299 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DESTACO, Stäubli, EAS change systems, Hilma-Römheld, Pascal Engineering, Festo, Hydraulics International, SMED Systems, SANDSUN, Kosmek, AIM Joraco, PFA Inc., Spreitzer GmbH & Co. KG, Ulbrich GmbH, Mould-Tip Injection Technology Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |