What is Global 5-Axis Gantry Machines Market?

The Global 5-Axis Gantry Machines Market is a specialized segment within the broader machine tool industry, focusing on advanced manufacturing equipment that offers enhanced precision and versatility. These machines are designed to perform complex machining tasks by moving a tool or a part along five different axes simultaneously. This capability allows for the creation of intricate and detailed components, which are essential in industries that demand high precision and efficiency. The gantry design, characterized by its bridge-like structure, provides stability and support, enabling the machine to handle large and heavy workpieces. This market is driven by the increasing demand for high-quality, complex parts in sectors such as aerospace, automotive, and energy. As industries continue to push the boundaries of innovation, the need for advanced manufacturing solutions like 5-axis gantry machines is expected to grow. These machines not only improve production efficiency but also reduce the need for multiple setups, thereby saving time and reducing costs. The global market is witnessing technological advancements, with manufacturers focusing on integrating automation and digitalization to enhance machine performance and user experience. As a result, the Global 5-Axis Gantry Machines Market is poised for significant growth in the coming years.

8000Rpm, 18000Rpm, 30000Rpm in the Global 5-Axis Gantry Machines Market:

In the Global 5-Axis Gantry Machines Market, spindle speeds such as 8000 RPM, 18000 RPM, and 30000 RPM play a crucial role in determining the machine's performance and suitability for various applications. The spindle speed, measured in revolutions per minute (RPM), directly impacts the cutting speed and the quality of the finished product. Machines with an 8000 RPM spindle speed are typically used for heavy-duty machining tasks where precision and stability are paramount. These machines are ideal for industries that require robust and durable components, such as the automotive and energy sectors. The lower spindle speed ensures that the machine can handle larger cutting tools and thicker materials without compromising on accuracy. On the other hand, machines with an 18000 RPM spindle speed offer a balance between speed and precision, making them suitable for a wide range of applications. These machines are often used in the aerospace industry, where the demand for lightweight and complex components is high. The higher spindle speed allows for faster material removal rates, which is essential for meeting tight production schedules. Additionally, the increased speed enhances the machine's ability to produce intricate details and smooth finishes, which are critical in aerospace applications. Machines with a 30000 RPM spindle speed represent the pinnacle of precision and speed in the Global 5-Axis Gantry Machines Market. These high-speed machines are designed for applications that require the utmost accuracy and surface finish, such as mold manufacturing and the production of high-precision components. The ability to operate at such high speeds allows these machines to achieve exceptional levels of detail and finish, making them indispensable in industries where quality cannot be compromised. Furthermore, the high spindle speed reduces the cycle time, enabling manufacturers to increase their production capacity and meet the growing demand for high-quality components. As the Global 5-Axis Gantry Machines Market continues to evolve, the importance of spindle speed in determining machine performance and application suitability cannot be overstated. Manufacturers are continually innovating to develop machines that offer higher speeds and greater precision, ensuring that they can meet the diverse needs of their customers. The choice of spindle speed ultimately depends on the specific requirements of the application, with each speed offering unique advantages and capabilities. Whether it's the robust performance of an 8000 RPM machine, the balanced versatility of an 18000 RPM machine, or the unparalleled precision of a 30000 RPM machine, the Global 5-Axis Gantry Machines Market offers a wide range of options to suit the needs of various industries.

Mold Manufacturing, Aerospace, Energy Equipment, Automobile in the Global 5-Axis Gantry Machines Market:

The Global 5-Axis Gantry Machines Market finds extensive usage across several key industries, including mold manufacturing, aerospace, energy equipment, and the automobile sector. In mold manufacturing, these machines are indispensable due to their ability to produce complex and precise molds with intricate details. The 5-axis capability allows for the creation of molds with undercuts and complex geometries, which are often required in industries such as automotive and consumer electronics. The precision and efficiency of these machines reduce the time and cost associated with mold production, enabling manufacturers to meet the high demands of their clients. In the aerospace industry, the need for lightweight and high-strength components is paramount. 5-axis gantry machines are used to manufacture critical aerospace parts such as turbine blades, structural components, and engine parts. The ability to machine complex shapes with high precision ensures that the components meet the stringent quality standards required in the aerospace sector. Additionally, the use of advanced materials such as titanium and composites in aerospace applications necessitates the use of high-performance machining solutions like 5-axis gantry machines. The energy equipment sector also benefits significantly from the capabilities of 5-axis gantry machines. These machines are used to manufacture components for wind turbines, gas turbines, and other energy generation equipment. The precision and versatility of 5-axis machining allow for the production of parts with complex geometries and tight tolerances, which are essential for the efficient operation of energy equipment. Furthermore, the ability to machine large and heavy components makes these machines ideal for the energy sector, where the size and weight of parts can be substantial. In the automobile industry, the demand for high-quality and complex components continues to grow. 5-axis gantry machines are used to manufacture a wide range of automotive parts, including engine components, transmission parts, and body panels. The precision and efficiency of these machines enable manufacturers to produce parts with intricate designs and tight tolerances, which are essential for the performance and safety of vehicles. Additionally, the use of 5-axis machining reduces the need for multiple setups and manual interventions, resulting in faster production times and lower costs. As the Global 5-Axis Gantry Machines Market continues to expand, its usage across these key industries is expected to grow, driven by the increasing demand for high-quality and complex components.

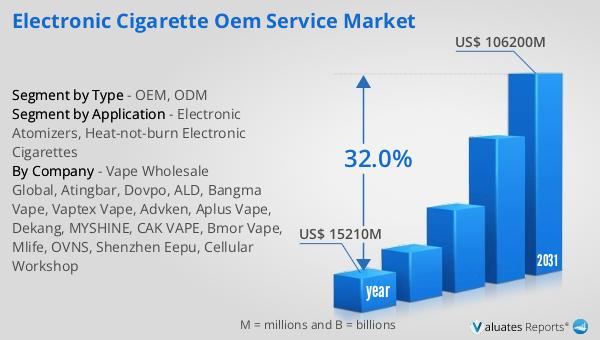

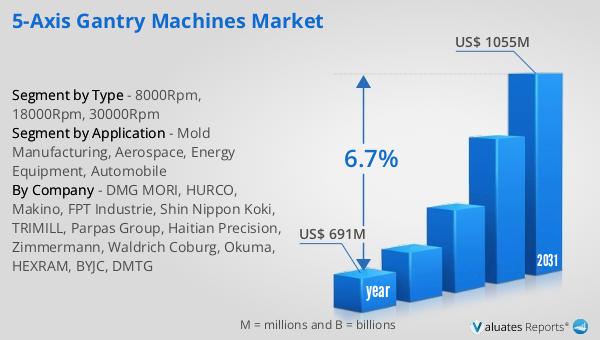

Global 5-Axis Gantry Machines Market Outlook:

The worldwide market for 5-Axis Gantry Machines was valued at $691 million in 2024 and is anticipated to expand to a revised size of $1,055 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.7% throughout the forecast period. This growth trajectory underscores the increasing demand for advanced manufacturing solutions that offer precision, efficiency, and versatility. The market's expansion is driven by the rising need for high-quality, complex components across various industries, including aerospace, automotive, and energy. As these sectors continue to innovate and push the boundaries of technology, the demand for sophisticated machining solutions like 5-axis gantry machines is expected to rise. The projected growth also highlights the ongoing advancements in machine tool technology, with manufacturers focusing on integrating automation and digitalization to enhance machine performance and user experience. As a result, the Global 5-Axis Gantry Machines Market is poised for significant growth, offering numerous opportunities for manufacturers and end-users alike. The market's robust growth prospects reflect the increasing importance of precision machining in today's fast-paced and competitive industrial landscape. As industries continue to evolve and adapt to changing market dynamics, the demand for advanced manufacturing solutions like 5-axis gantry machines is expected to remain strong, driving the market's growth in the coming years.

| Report Metric | Details |

| Report Name | 5-Axis Gantry Machines Market |

| Accounted market size in year | US$ 691 million |

| Forecasted market size in 2031 | US$ 1055 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DMG MORI, HURCO, Makino, FPT Industrie, Shin Nippon Koki, TRIMILL, Parpas Group, Haitian Precision, Zimmermann, Waldrich Coburg, Okuma, HEXRAM, BYJC, DMTG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |