What is Global High-Precision Conductivity Sensor Market?

The Global High-Precision Conductivity Sensor Market is a specialized segment within the broader sensor industry, focusing on devices that measure the electrical conductivity of solutions with high accuracy. These sensors are crucial in various industries, including water treatment, chemical processing, and food and beverage production, where precise measurement of ionic content is essential for quality control and process optimization. High-precision conductivity sensors are designed to provide reliable and accurate readings, even in challenging environments, making them indispensable tools for ensuring product quality and compliance with industry standards. The market for these sensors is driven by the increasing demand for high-quality products and the need for efficient process control in various industries. As industries continue to prioritize precision and efficiency, the demand for high-precision conductivity sensors is expected to grow, offering opportunities for innovation and development in sensor technology. The market is characterized by a diverse range of products, including two-electrode and four-electrode sensors, each offering unique advantages and applications. As technology advances, the market is likely to see further innovations that enhance the accuracy, reliability, and versatility of these sensors, catering to the evolving needs of industries worldwide.

Two-Electrode Conductivity Sensor, Four-Electrode Conductivity Sensor, Others in the Global High-Precision Conductivity Sensor Market:

Two-electrode conductivity sensors are among the most common types of sensors used in the Global High-Precision Conductivity Sensor Market. These sensors operate by passing an electrical current between two electrodes immersed in a solution, measuring the voltage drop to determine the solution's conductivity. They are known for their simplicity and cost-effectiveness, making them suitable for a wide range of applications. However, they can be susceptible to polarization effects, which can affect accuracy, especially in solutions with high conductivity. To mitigate this, two-electrode sensors are often used in applications where the conductivity range is moderate, and the risk of polarization is minimal. On the other hand, four-electrode conductivity sensors are designed to overcome the limitations of two-electrode sensors. By using four electrodes, these sensors can eliminate polarization effects, providing more accurate and stable readings across a broader range of conductivities. The additional electrodes allow for separate current and voltage measurements, ensuring that the sensor's readings are not influenced by electrode polarization. This makes four-electrode sensors ideal for applications requiring high precision and reliability, such as in the chemical industry, where accurate conductivity measurements are critical for process control and quality assurance. In addition to two-electrode and four-electrode sensors, the Global High-Precision Conductivity Sensor Market also includes other types of sensors, such as inductive or toroidal conductivity sensors. These sensors do not rely on direct contact with the solution, making them suitable for applications where fouling or coating of electrodes is a concern. Inductive sensors work by generating an electromagnetic field and measuring the induced current in the solution, providing accurate conductivity measurements without the risk of electrode contamination. This makes them ideal for use in harsh environments or with solutions that are prone to fouling. Each type of conductivity sensor offers unique advantages and is suited to specific applications, allowing industries to choose the most appropriate sensor for their needs. As the demand for high-precision conductivity measurements continues to grow, the market is likely to see further innovations in sensor technology, enhancing the accuracy, reliability, and versatility of these essential tools.

Water Treatment, Chemical Industry, Food & Beverage, Others in the Global High-Precision Conductivity Sensor Market:

The Global High-Precision Conductivity Sensor Market plays a crucial role in various industries, including water treatment, chemical processing, and food and beverage production. In water treatment, high-precision conductivity sensors are used to monitor and control the ionic content of water, ensuring that it meets the required quality standards for consumption or industrial use. These sensors help in detecting impurities and contaminants, allowing for timely intervention and treatment to maintain water quality. In the chemical industry, conductivity sensors are essential for process control and quality assurance. They are used to monitor the concentration of chemical solutions, ensuring that the desired chemical reactions occur efficiently and safely. Accurate conductivity measurements are critical for optimizing production processes, reducing waste, and ensuring product quality. In the food and beverage industry, high-precision conductivity sensors are used to monitor the concentration of ingredients and additives, ensuring that products meet the required quality and safety standards. These sensors help in maintaining consistency and quality in food and beverage production, contributing to consumer satisfaction and brand reputation. Additionally, conductivity sensors are used in various other industries, such as pharmaceuticals, where they play a vital role in ensuring the quality and safety of products. As industries continue to prioritize quality and efficiency, the demand for high-precision conductivity sensors is expected to grow, driving innovation and development in sensor technology.

Global High-Precision Conductivity Sensor Market Outlook:

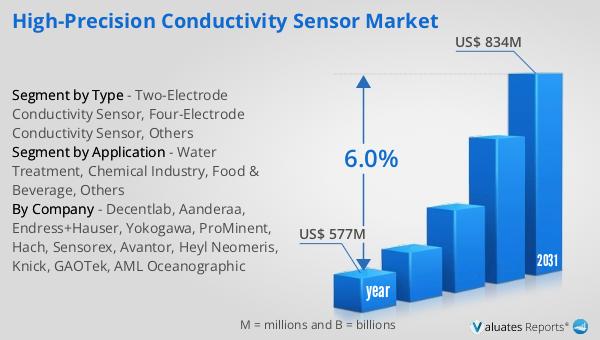

The global market for high-precision conductivity sensors was valued at $577 million in 2024 and is anticipated to expand to a revised size of $834 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.0% over the forecast period. This growth trajectory underscores the increasing demand for accurate and reliable conductivity measurements across various industries. As industries strive for greater precision and efficiency in their processes, the need for high-precision conductivity sensors is becoming more pronounced. These sensors are essential for ensuring product quality, optimizing production processes, and maintaining compliance with industry standards. The projected growth of the market indicates a robust demand for these sensors, driven by advancements in sensor technology and the increasing emphasis on quality control and process optimization. As the market continues to evolve, it is likely to see further innovations that enhance the accuracy, reliability, and versatility of high-precision conductivity sensors, catering to the diverse needs of industries worldwide. The growth of the market also presents opportunities for manufacturers and suppliers to expand their product offerings and capture a larger share of the market, contributing to the overall development of the sensor industry.

| Report Metric | Details |

| Report Name | High-Precision Conductivity Sensor Market |

| Accounted market size in year | US$ 577 million |

| Forecasted market size in 2031 | US$ 834 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Decentlab, Aanderaa, Endress+Hauser, Yokogawa, ProMinent, Hach, Sensorex, Avantor, Heyl Neomeris, Knick, GAOTek, AML Oceanographic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |