What is Global Electronic Grade Specialty Gases Market?

The Global Electronic Grade Specialty Gases Market is a crucial segment within the broader specialty gases industry, focusing on gases that meet the high purity standards required for electronic applications. These gases are essential in the manufacturing processes of semiconductors, flat panel displays, and photovoltaic cells, among others. The market is driven by the increasing demand for consumer electronics, advancements in technology, and the growing adoption of renewable energy sources. Electronic grade specialty gases include a variety of gases such as nitrogen, hydrogen, helium, and others, which are used in different stages of electronic component manufacturing. The market is characterized by stringent quality standards and regulations to ensure the purity and performance of these gases. As technology continues to evolve, the demand for high-quality electronic grade specialty gases is expected to rise, making this market a vital component of the global electronics industry. The market's growth is also supported by the expansion of the electronics manufacturing sector in emerging economies, where there is a significant push towards modernization and technological advancement. Overall, the Global Electronic Grade Specialty Gases Market plays a pivotal role in supporting the electronics industry's growth and innovation.

Single Gas, Mixed Gas in the Global Electronic Grade Specialty Gases Market:

In the Global Electronic Grade Specialty Gases Market, gases are categorized into single gases and mixed gases, each serving distinct purposes in electronic manufacturing. Single gases refer to pure gases that are used individually in various processes. These include gases like nitrogen, hydrogen, helium, and argon, which are critical in processes such as etching, deposition, and cleaning in semiconductor manufacturing. Nitrogen, for instance, is widely used for purging and inerting applications due to its inert nature, preventing unwanted chemical reactions during manufacturing. Hydrogen is often used in annealing processes to improve the electrical properties of semiconductors. Helium, known for its low boiling point, is utilized in cooling applications and leak detection. Argon, another inert gas, is used in sputtering processes to deposit thin films on substrates. On the other hand, mixed gases are combinations of two or more gases tailored to meet specific process requirements. These mixtures are designed to optimize performance and efficiency in manufacturing processes. For example, a mixture of hydrogen and nitrogen, known as forming gas, is used in annealing and heat treatment processes to prevent oxidation and improve the quality of electronic components. Mixed gases are also used in chemical vapor deposition (CVD) and plasma-enhanced chemical vapor deposition (PECVD) processes, where precise control over gas composition is crucial for achieving desired film properties. The choice between single and mixed gases depends on the specific requirements of the manufacturing process, with factors such as purity, reactivity, and cost playing a significant role in decision-making. The market for both single and mixed gases is driven by the continuous advancements in electronic manufacturing technologies, which demand higher precision and efficiency. As the electronics industry evolves, the need for specialized gas solutions that can meet the stringent quality and performance standards becomes increasingly important. This has led to ongoing research and development efforts to create innovative gas mixtures and improve the purity levels of single gases. The Global Electronic Grade Specialty Gases Market is thus characterized by a dynamic interplay between technological advancements and the evolving needs of the electronics industry, with single and mixed gases playing a central role in enabling cutting-edge manufacturing processes.

Semiconductor, Photovoltaic, Others in the Global Electronic Grade Specialty Gases Market:

The usage of Global Electronic Grade Specialty Gases Market spans several critical areas, including semiconductors, photovoltaics, and other electronic applications. In the semiconductor industry, these gases are indispensable for various manufacturing processes. They are used in etching, where gases like fluorine and chlorine are employed to remove material from the surface of semiconductor wafers, creating intricate patterns necessary for integrated circuits. Deposition processes, such as chemical vapor deposition (CVD) and physical vapor deposition (PVD), also rely heavily on specialty gases to form thin films on substrates. Gases like silane, ammonia, and nitrous oxide are commonly used in these processes to deposit materials with precise thickness and composition. Additionally, specialty gases are used in doping processes, where elements like boron and phosphorus are introduced into the semiconductor material to modify its electrical properties. In the photovoltaic industry, electronic grade specialty gases are crucial for the production of solar cells. Gases such as silane and hydrogen are used in the deposition of thin-film silicon layers, which are essential for the efficiency and performance of solar panels. The demand for clean and renewable energy sources has driven significant growth in the photovoltaic sector, leading to increased consumption of specialty gases. These gases play a vital role in enhancing the efficiency of solar cells, thereby contributing to the overall growth of the renewable energy market. Beyond semiconductors and photovoltaics, electronic grade specialty gases find applications in other areas such as flat panel displays, LEDs, and optical fibers. In the production of flat panel displays, gases like nitrogen trifluoride are used for cleaning and etching processes, ensuring the high quality and performance of the displays. LEDs, which are widely used in lighting and display technologies, also rely on specialty gases for the deposition of semiconductor layers. Optical fibers, essential for telecommunications, require high-purity gases for the deposition of glass layers, ensuring low signal loss and high transmission quality. Overall, the Global Electronic Grade Specialty Gases Market is integral to the advancement of various electronic technologies, supporting innovation and efficiency across multiple industries.

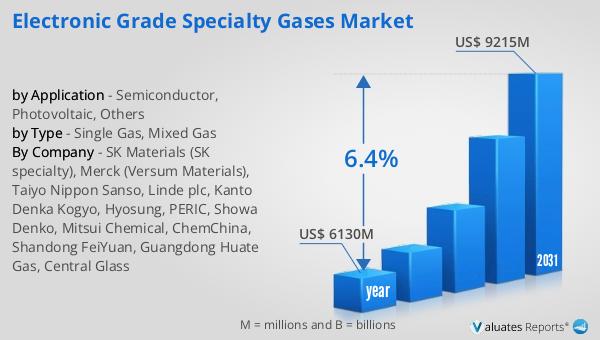

Global Electronic Grade Specialty Gases Market Outlook:

The global market for Electronic Grade Specialty Gases was valued at $6,130 million in 2024 and is anticipated to expand to a revised size of $9,215 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.4% over the forecast period. This growth trajectory underscores the increasing demand for high-purity gases in the electronics industry, driven by advancements in technology and the rising adoption of electronic devices worldwide. The market's expansion is fueled by the growing need for semiconductors, flat panel displays, and photovoltaic cells, all of which require specialty gases for their manufacturing processes. As the electronics industry continues to evolve, the demand for electronic grade specialty gases is expected to rise, supported by the expansion of electronics manufacturing in emerging economies. The market's growth is also influenced by the increasing focus on renewable energy sources, which drives the demand for photovoltaic cells and, consequently, the specialty gases used in their production. Additionally, the stringent quality standards and regulations governing the production and use of electronic grade specialty gases ensure that only the highest quality gases are used in manufacturing processes, further driving market growth. Overall, the Global Electronic Grade Specialty Gases Market is poised for significant growth, driven by technological advancements and the increasing demand for high-quality electronic components.

| Report Metric | Details |

| Report Name | Electronic Grade Specialty Gases Market |

| Accounted market size in year | US$ 6130 million |

| Forecasted market size in 2031 | US$ 9215 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SK Materials (SK specialty), Merck (Versum Materials), Taiyo Nippon Sanso, Linde plc, Kanto Denka Kogyo, Hyosung, PERIC, Showa Denko, Mitsui Chemical, ChemChina, Shandong FeiYuan, Guangdong Huate Gas, Central Glass |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |