What is Global Wine Capsule Machines Market?

The Global Wine Capsule Machines Market is a specialized segment within the broader packaging machinery industry, focusing on the production of capsules used to seal wine bottles. These capsules, often made from materials like PVC, aluminum, or tin, serve both functional and aesthetic purposes. They protect the cork from damage and contamination while also enhancing the visual appeal of the wine bottle. The market for wine capsule machines is driven by the growing global wine industry, which demands efficient and high-quality packaging solutions. These machines are designed to produce capsules at varying speeds and capacities, catering to different production needs of wineries, from small boutique operations to large-scale producers. The market is characterized by technological advancements aimed at improving the efficiency, precision, and versatility of these machines. As consumer preferences evolve and the demand for premium and diverse wine products increases, the wine capsule machines market is expected to grow, offering innovative solutions to meet the changing needs of the wine industry. The market's growth is also influenced by trends such as sustainability, with manufacturers exploring eco-friendly materials and processes to align with environmental concerns.

< 200 Capsules/min, 200-300 Capsules/min, > 300 Capsules/min in the Global Wine Capsule Machines Market:

In the Global Wine Capsule Machines Market, the production speed of machines is a critical factor that influences the efficiency and output of wine capsule manufacturing. Machines are categorized based on their production capacity, typically measured in capsules per minute. The first category, machines producing less than 200 capsules per minute, is often favored by small to medium-sized wineries or boutique producers. These machines are designed for lower volume production, offering flexibility and ease of use. They are ideal for businesses that prioritize quality over quantity, allowing for customization and attention to detail in capsule design and production. Despite their lower output, these machines are equipped with advanced features to ensure precision and consistency in capsule manufacturing. The second category includes machines that produce between 200 to 300 capsules per minute. These machines strike a balance between speed and quality, making them suitable for medium to large-scale wineries that require a higher production capacity without compromising on the quality of the capsules. They are often equipped with automated systems and advanced technology to enhance efficiency and reduce labor costs. The third category comprises machines capable of producing more than 300 capsules per minute. These high-speed machines are designed for large-scale production facilities that need to meet high demand and tight production schedules. They are equipped with state-of-the-art technology to ensure high precision and consistency, even at maximum output. These machines are essential for large wineries and packaging companies that supply capsules to multiple clients or export to international markets. The ability to produce a large volume of capsules quickly and efficiently is crucial for meeting the demands of the global wine industry. Each category of machines plays a vital role in the wine capsule manufacturing process, catering to different production needs and helping wineries optimize their operations. As the wine industry continues to grow and evolve, the demand for efficient and versatile wine capsule machines is expected to increase, driving innovation and development in this specialized market segment.

PVC Capsules, Aluminum Capsules, Tin Capsules, Others in the Global Wine Capsule Machines Market:

The Global Wine Capsule Machines Market serves a diverse range of applications, with different types of capsules catering to various needs within the wine industry. PVC capsules are among the most commonly used, known for their flexibility, durability, and cost-effectiveness. These capsules are popular among wineries due to their ease of application and ability to provide a tight seal, protecting the wine from external elements. PVC capsules are available in a wide range of colors and designs, allowing wineries to customize their packaging to reflect their brand identity. Aluminum capsules, on the other hand, are favored for their premium appearance and superior protective qualities. They offer excellent resistance to moisture and oxygen, ensuring the wine remains in optimal condition. Aluminum capsules are often used for high-end wines, where the quality of packaging is as important as the quality of the wine itself. Tin capsules are considered the most luxurious option, offering a sophisticated and elegant finish to wine bottles. They are highly malleable, allowing for intricate designs and embossing, which can enhance the visual appeal of the product. Tin capsules are typically used for premium and vintage wines, where the packaging plays a crucial role in conveying the exclusivity and quality of the product. In addition to these traditional materials, the market also includes other types of capsules, such as those made from biodegradable or eco-friendly materials. As sustainability becomes a key concern for consumers and producers alike, there is a growing demand for capsules that minimize environmental impact. These alternative materials offer wineries the opportunity to align their packaging practices with their sustainability goals, appealing to environmentally conscious consumers. The versatility of wine capsule machines allows them to accommodate different materials and designs, providing wineries with the flexibility to choose the best option for their products. As the wine industry continues to innovate and diversify, the demand for specialized wine capsule machines that can produce a wide range of capsule types is expected to grow, driving further advancements in this market.

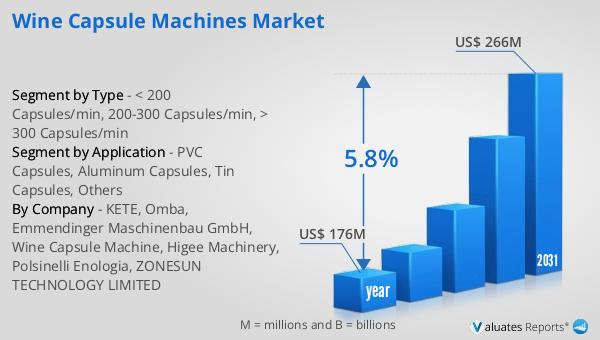

Global Wine Capsule Machines Market Outlook:

The global market for wine capsule machines is experiencing significant growth, with its value estimated at $176 million in 2024. This market is projected to expand to a revised size of $266 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% during the forecast period. This growth is driven by several factors, including the increasing demand for wine worldwide and the need for efficient and high-quality packaging solutions. As the wine industry continues to expand, wineries are seeking advanced machinery that can enhance their production capabilities and meet the diverse needs of consumers. The projected growth of the wine capsule machines market indicates a strong demand for innovative and versatile packaging solutions that can cater to the evolving preferences of wine producers and consumers. The market's expansion is also influenced by technological advancements in machinery, which are improving the efficiency, precision, and versatility of wine capsule production. As wineries strive to differentiate their products and enhance their brand image, the demand for high-quality and customizable wine capsules is expected to rise. This trend is likely to drive further innovation and development in the wine capsule machines market, offering new opportunities for manufacturers and suppliers in this specialized industry.

| Report Metric | Details |

| Report Name | Wine Capsule Machines Market |

| Accounted market size in year | US$ 176 million |

| Forecasted market size in 2031 | US$ 266 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KETE, Omba, Emmendinger Maschinenbau GmbH, Wine Capsule Machine, Higee Machinery, Polsinelli Enologia, ZONESUN TECHNOLOGY LIMITED |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |