What is Global Laboratory Grinder Machine Market?

The Global Laboratory Grinder Machine Market is a specialized segment within the broader laboratory equipment industry, focusing on devices designed to grind, crush, or pulverize materials into fine particles for analysis and research purposes. These machines are essential in various scientific and industrial applications, providing precise and efficient sample preparation. Laboratory grinder machines are used in diverse fields such as pharmaceuticals, agriculture, food processing, and chemical research, where they help in breaking down complex materials into manageable sizes for further examination. The market for these machines is driven by the increasing demand for high-quality, reliable, and efficient laboratory equipment that can handle a wide range of materials. Technological advancements have led to the development of more sophisticated and user-friendly grinder machines, enhancing their functionality and appeal. As research and development activities continue to expand globally, the need for advanced laboratory equipment, including grinder machines, is expected to grow, making this market a vital component of the scientific and industrial landscape. The market's growth is also supported by the rising focus on quality control and standardization in various industries, which necessitates precise and consistent sample preparation.

Ball Mill, Disc Mill, Rotor Mill, Cutting Mill, Others in the Global Laboratory Grinder Machine Market:

In the Global Laboratory Grinder Machine Market, several types of machines are prominent, each serving specific purposes and offering unique advantages. The Ball Mill is a versatile grinder that uses balls as the grinding medium. It is widely used for grinding materials into fine powder, making it ideal for applications in pharmaceuticals, ceramics, and mineral processing. The ball mill operates by rotating a cylinder filled with grinding balls and the material to be ground, which results in the balls impacting and grinding the material into a fine powder. This type of mill is known for its efficiency and ability to handle both wet and dry materials. The Disc Mill, on the other hand, uses a pair of discs to grind materials. It is particularly effective for grinding brittle materials and is commonly used in the food and agriculture industries. The disc mill's design allows for precise control over the particle size, making it suitable for applications requiring uniform particle distribution. Rotor Mills are another type of laboratory grinder, characterized by their high-speed rotors that create a shearing action to grind materials. These mills are ideal for processing soft to medium-hard materials and are often used in the chemical and pharmaceutical industries. The high-speed operation of rotor mills allows for rapid grinding and efficient sample preparation. Cutting Mills are designed for grinding fibrous and tough materials. They use sharp blades to cut materials into smaller pieces, making them suitable for applications in the plastics, textiles, and recycling industries. Cutting mills are known for their ability to handle a wide range of materials and their ease of use. Lastly, the category of "Others" includes various specialized grinder machines that cater to niche applications. These machines may include cryogenic grinders, which use liquid nitrogen to freeze and grind materials, or planetary ball mills, which offer high-energy grinding for specific applications. Each type of laboratory grinder machine plays a crucial role in the market, providing solutions for different grinding needs and contributing to the overall growth and development of the industry.

Bio & Pharmaceutical, Agriculture & Food, Chemical Material, Other in the Global Laboratory Grinder Machine Market:

The Global Laboratory Grinder Machine Market finds extensive usage across various sectors, each with unique requirements and applications. In the Bio & Pharmaceutical industry, laboratory grinder machines are essential for the preparation of samples for analysis and research. These machines help in grinding active pharmaceutical ingredients (APIs) and other compounds into fine powders, facilitating the development of new drugs and formulations. The precise and efficient grinding capabilities of these machines ensure that the samples are of consistent quality, which is crucial for accurate analysis and testing. In the Agriculture & Food sector, laboratory grinder machines are used to process samples of grains, seeds, and other agricultural products. These machines help in determining the quality and composition of agricultural products, enabling researchers and producers to improve crop yields and food quality. The ability to grind samples into fine particles allows for detailed analysis of nutritional content, contaminants, and other factors that affect food safety and quality. In the Chemical Material industry, laboratory grinder machines are used to grind and mix chemical compounds for research and development purposes. These machines enable researchers to create new materials and test their properties, contributing to advancements in fields such as materials science and nanotechnology. The precise control over particle size and distribution provided by these machines is essential for developing new chemical formulations and products. Other industries, such as environmental science and geology, also rely on laboratory grinder machines for sample preparation and analysis. These machines help in grinding soil, rock, and other materials for testing and research, providing valuable insights into environmental conditions and geological formations. Overall, the Global Laboratory Grinder Machine Market plays a vital role in supporting research and development activities across various industries, enabling advancements in science and technology.

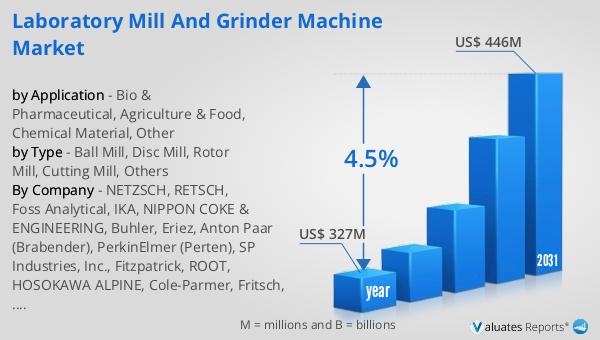

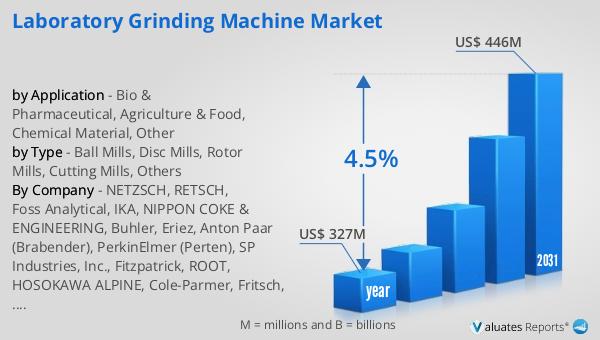

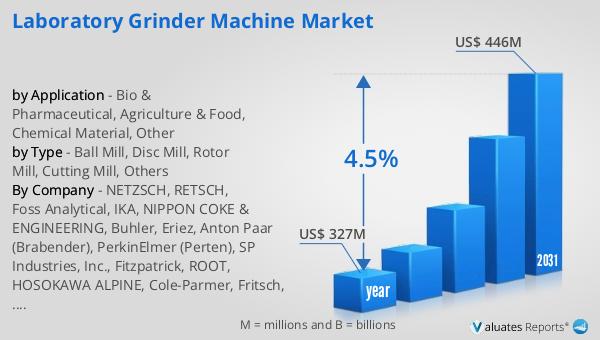

Global Laboratory Grinder Machine Market Outlook:

The global market for Laboratory Grinder Machines was valued at $327 million in 2024 and is anticipated to grow to a revised size of $446 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% over the forecast period. The Asia-Pacific region emerges as the largest consumer market for these devices, accounting for approximately 36% of the global market. This dominance is largely driven by the rapid industrialization and technological advancements occurring in the region. The increasing demand for laboratory grinder machines in Asia-Pacific can be attributed to the expanding pharmaceutical, food processing, and chemical industries, which require efficient and reliable equipment for sample preparation and analysis. Additionally, the region's focus on research and development activities, coupled with government initiatives to promote scientific and technological advancements, further fuels the demand for these machines. As industries continue to evolve and expand in the Asia-Pacific region, the need for high-quality laboratory equipment, including grinder machines, is expected to rise, contributing to the overall growth of the market. The market's expansion is also supported by the increasing emphasis on quality control and standardization across various industries, which necessitates precise and consistent sample preparation.

| Report Metric | Details |

| Report Name | Laboratory Grinder Machine Market |

| Accounted market size in year | US$ 327 million |

| Forecasted market size in 2031 | US$ 446 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NETZSCH, RETSCH, Foss Analytical, IKA, NIPPON COKE & ENGINEERING, Buhler, Eriez, Anton Paar (Brabender), PerkinElmer (Perten), SP Industries, Inc., Fitzpatrick, ROOT, HOSOKAWA ALPINE, Cole-Parmer, Fritsch, SIEBTECHNIK GMBH, Ortoalresa, SIEHE, Malvern Panalytical, Kinematica, RUCCA, VIBROTECHNIK |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |