What is Global NDT for Electronics Market?

The Global Non-Destructive Testing (NDT) for Electronics Market is a specialized segment within the broader NDT industry, focusing on the application of non-invasive testing techniques to evaluate the integrity and functionality of electronic components and systems. This market is driven by the increasing complexity and miniaturization of electronic devices, which necessitate precise and reliable testing methods to ensure quality and performance. NDT methods are crucial in identifying defects, inconsistencies, or potential failures in electronic products without causing any damage, thus preserving their usability. The market encompasses a variety of testing techniques, each suited to different aspects of electronic testing, such as detecting surface and subsurface defects, assessing material properties, and ensuring the reliability of electronic assemblies. As electronics continue to evolve, with advancements in technology and increasing demand for high-performance devices, the role of NDT becomes even more critical. This market is characterized by continuous innovation, with companies investing in research and development to enhance testing capabilities and meet the stringent quality standards required by industries such as consumer electronics, automotive, aerospace, and telecommunications. The Global NDT for Electronics Market is poised for growth as it adapts to the changing landscape of the electronics industry, ensuring that products meet the highest standards of safety and performance.

Ultrasonic Testing (UT), Radiographic Testing (RT), Eddy Current Testing (ECT), Infrared Thermal Imaging Testing (IRT), Laser Speckle Testing (LST), Others in the Global NDT for Electronics Market:

Ultrasonic Testing (UT) is a widely used NDT method in the electronics market, employing high-frequency sound waves to detect internal flaws or characterize materials. In electronics, UT is particularly useful for inspecting solder joints, detecting delaminations, and assessing the integrity of composite materials. The technique involves transmitting ultrasonic waves into a material and analyzing the reflected signals to identify any anomalies. This method is non-invasive and provides precise measurements, making it ideal for quality control in manufacturing processes. Radiographic Testing (RT), on the other hand, utilizes X-rays or gamma rays to create images of the internal structure of electronic components. This technique is invaluable for identifying hidden defects such as voids, cracks, or misalignments in circuit boards and semiconductor devices. RT offers a detailed view of the internal configuration, allowing for accurate assessment and quality assurance. Eddy Current Testing (ECT) is another NDT technique that uses electromagnetic induction to detect surface and near-surface defects in conductive materials. In the electronics industry, ECT is often employed to inspect conductive paths and connections, ensuring the integrity of electrical circuits. This method is highly sensitive and can detect minute defects that might affect the performance of electronic devices. Infrared Thermal Imaging Testing (IRT) is a non-contact method that uses infrared cameras to detect heat patterns and anomalies in electronic components. IRT is particularly effective in identifying overheating issues, short circuits, or thermal inefficiencies in electronic assemblies. By visualizing temperature variations, IRT helps in diagnosing potential problems before they lead to failures. Laser Speckle Testing (LST) is a relatively newer technique that uses laser light to detect surface deformations and vibrations in electronic components. LST is highly sensitive and can detect minute changes in surface conditions, making it suitable for assessing the mechanical stability of electronic devices. This method is particularly useful in the development and testing of microelectromechanical systems (MEMS) and other precision electronic components. Other NDT methods in the electronics market include acoustic emission testing, which monitors the release of energy from materials under stress, and visual inspection, which involves the manual examination of components for visible defects. Each of these methods has its unique advantages and applications, contributing to the comprehensive assessment of electronic products. As the electronics industry continues to advance, the demand for sophisticated NDT techniques will grow, driving innovation and enhancing the reliability and performance of electronic devices.

Electronic Component Testing, Circuit Board Testing, Packaging Structure Testing, Others in the Global NDT for Electronics Market:

The Global NDT for Electronics Market plays a crucial role in various areas, including electronic component testing, circuit board testing, packaging structure testing, and others. In electronic component testing, NDT methods are employed to ensure the quality and reliability of individual components such as resistors, capacitors, and semiconductors. Techniques like ultrasonic testing and eddy current testing are used to detect internal defects, assess material properties, and verify the integrity of connections. This ensures that components meet the required specifications and function as intended in electronic assemblies. Circuit board testing is another critical application of NDT in the electronics market. Circuit boards are the backbone of electronic devices, and any defects can lead to significant performance issues or failures. Radiographic testing and infrared thermal imaging are commonly used to inspect circuit boards for hidden defects, such as voids, cracks, or misalignments. These methods provide detailed insights into the internal structure of circuit boards, allowing for accurate assessment and quality assurance. Packaging structure testing is essential to ensure the durability and reliability of electronic products during transportation and use. NDT techniques like laser speckle testing and acoustic emission testing are employed to assess the mechanical stability and integrity of packaging materials. These methods help identify potential weaknesses or vulnerabilities that could compromise the safety and performance of electronic products. Other areas where NDT is used in the electronics market include the testing of microelectromechanical systems (MEMS), sensors, and other precision components. As electronic devices become more complex and miniaturized, the need for advanced NDT techniques to ensure quality and reliability becomes increasingly important. The Global NDT for Electronics Market is characterized by continuous innovation and development, with companies investing in research and development to enhance testing capabilities and meet the evolving needs of the electronics industry.

Global NDT for Electronics Market Outlook:

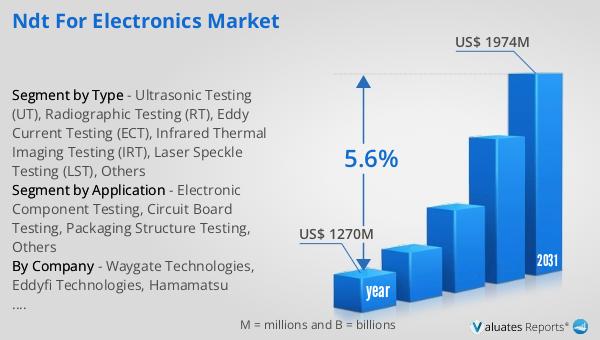

The worldwide market for Non-Destructive Testing (NDT) in the electronics sector was valued at approximately $1.27 billion in 2024. It is anticipated to expand significantly, reaching an estimated $1.974 billion by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 5.6% over the forecast period. This upward trend is indicative of the increasing demand for reliable and efficient testing methods in the electronics industry, driven by the rapid advancement of technology and the growing complexity of electronic devices. As electronic products become more sophisticated, the need for precise and non-invasive testing techniques becomes paramount to ensure quality and performance. The market's expansion is also fueled by the rising adoption of NDT methods across various sectors, including consumer electronics, automotive, aerospace, and telecommunications. These industries require stringent quality control measures to meet the high standards of safety and performance expected by consumers and regulatory bodies. The projected growth of the Global NDT for Electronics Market underscores the importance of continuous innovation and development in testing technologies to keep pace with the evolving demands of the electronics industry. As companies invest in research and development to enhance their testing capabilities, the market is poised for sustained growth, ensuring that electronic products meet the highest standards of quality and reliability.

| Report Metric | Details |

| Report Name | NDT for Electronics Market |

| Accounted market size in year | US$ 1270 million |

| Forecasted market size in 2031 | US$ 1974 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Waygate Technologies, Eddyfi Technologies, Hamamatsu Photonics, ROLAND ELECTRONIC GmbH, SVK Electronics, Nexxis, Cairnhill Metrology, Applus+ Laboratories, FORCE Technology, TWI, SGS, Zetec, Infinita Lab |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |