What is Global Hydraulic Oil Filter Element Market?

The Global Hydraulic Oil Filter Element Market is a specialized segment within the broader industrial filtration industry, focusing on the production and distribution of filter elements specifically designed for hydraulic systems. These filter elements are crucial components in maintaining the cleanliness and efficiency of hydraulic fluids, which are used to transmit power in various industrial applications. The market encompasses a wide range of products, including high-pressure, medium-pressure, and low-pressure filter elements, each tailored to specific operational requirements. The demand for hydraulic oil filter elements is driven by the need to enhance the longevity and performance of hydraulic systems, reduce maintenance costs, and prevent system failures caused by contamination. As industries continue to expand and modernize, the market for these filter elements is expected to grow, driven by technological advancements and increasing awareness of the importance of fluid cleanliness. The market is characterized by a diverse range of manufacturers and suppliers, offering products that vary in terms of size, material, and filtration efficiency, catering to the specific needs of different industries such as mining, oil and gas, and construction.

High Pressure, Medium Pressure, Low Pressure in the Global Hydraulic Oil Filter Element Market:

In the Global Hydraulic Oil Filter Element Market, pressure ratings play a critical role in determining the suitability of filter elements for various applications. High-pressure filter elements are designed to withstand and operate efficiently under extreme pressure conditions, typically above 3000 psi. These filters are essential in heavy-duty applications where hydraulic systems are subjected to intense pressure, such as in industrial machinery, aerospace, and heavy equipment. The robust construction of high-pressure filters ensures that they can handle the stress without compromising the filtration efficiency, thereby protecting sensitive components from contaminants that could lead to system failures. Medium-pressure filter elements, on the other hand, are used in applications where the pressure ranges between 1500 psi and 3000 psi. These filters are commonly found in mobile equipment, agricultural machinery, and industrial applications where moderate pressure levels are prevalent. They offer a balance between durability and cost-effectiveness, providing adequate protection against contaminants while maintaining system efficiency. Low-pressure filter elements are designed for applications where the pressure is below 1500 psi. These filters are typically used in return lines and low-pressure circuits, where the risk of contamination is lower, but maintaining fluid cleanliness is still crucial for system performance. The construction of low-pressure filters is generally less robust compared to high and medium-pressure filters, making them more cost-effective for applications with less demanding pressure requirements. Across all pressure categories, the primary function of hydraulic oil filter elements is to remove particulate contaminants from the hydraulic fluid, thereby preventing wear and tear on system components, reducing downtime, and extending the lifespan of the equipment. The choice of filter element depends on various factors, including the operating pressure, flow rate, fluid type, and the specific requirements of the application. Manufacturers in the Global Hydraulic Oil Filter Element Market offer a wide range of products to cater to these diverse needs, with innovations in filter media and design continually enhancing the performance and reliability of these essential components.

Mining, Oil & gas, Architecture, Others in the Global Hydraulic Oil Filter Element Market:

The Global Hydraulic Oil Filter Element Market finds extensive usage across various industries, each with unique requirements and challenges. In the mining industry, hydraulic systems are integral to the operation of heavy machinery such as excavators, loaders, and drilling equipment. The harsh and dusty environment of mining operations necessitates the use of high-performance hydraulic oil filter elements to protect the hydraulic systems from contaminants that could lead to equipment failure and costly downtime. These filters ensure that the hydraulic fluid remains clean, thereby enhancing the efficiency and reliability of the machinery, which is crucial for maintaining productivity in mining operations. In the oil and gas sector, hydraulic systems are used in drilling rigs, offshore platforms, and various other equipment. The demanding nature of this industry, with its exposure to extreme conditions and the need for precise control, makes the use of high-quality hydraulic oil filter elements essential. These filters help in maintaining the cleanliness of the hydraulic fluid, which is vital for the smooth operation of equipment and the prevention of costly breakdowns. In the field of architecture and construction, hydraulic systems are employed in a wide range of machinery, including cranes, bulldozers, and concrete pumps. The efficiency and reliability of these machines are heavily dependent on the cleanliness of the hydraulic fluid, making the use of effective hydraulic oil filter elements a necessity. These filters help in reducing wear and tear on the machinery, thereby extending their lifespan and reducing maintenance costs. Beyond these specific industries, hydraulic oil filter elements are also used in various other applications, including manufacturing, agriculture, and transportation. In each of these areas, the primary function of the filters remains the same: to ensure the cleanliness of the hydraulic fluid, thereby enhancing the performance and reliability of the hydraulic systems. The versatility and importance of hydraulic oil filter elements make them a critical component in a wide range of industrial applications, driving the growth and development of the Global Hydraulic Oil Filter Element Market.

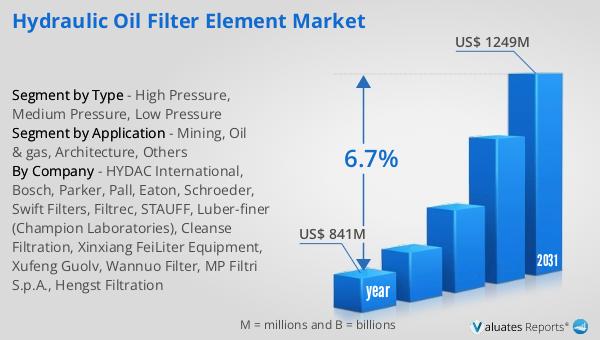

Global Hydraulic Oil Filter Element Market Outlook:

The global market for Hydraulic Oil Filter Elements was valued at approximately $841 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $1,249 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.7% over the forecast period. The increasing demand for hydraulic oil filter elements is driven by the need for efficient and reliable hydraulic systems across various industries. As industries continue to expand and modernize, the importance of maintaining clean hydraulic fluids becomes paramount, leading to a greater reliance on high-quality filter elements. The market's growth is also supported by technological advancements in filter design and materials, which enhance the performance and longevity of these essential components. Additionally, the rising awareness of the benefits of fluid cleanliness, such as reduced maintenance costs and improved system efficiency, is contributing to the increased adoption of hydraulic oil filter elements. The market is characterized by a diverse range of manufacturers and suppliers, offering products that cater to the specific needs of different industries, including mining, oil and gas, construction, and more. As the demand for hydraulic oil filter elements continues to grow, the market is expected to witness further innovation and development, ensuring that these critical components remain at the forefront of industrial filtration solutions.

| Report Metric | Details |

| Report Name | Hydraulic Oil Filter Element Market |

| Accounted market size in year | US$ 841 million |

| Forecasted market size in 2031 | US$ 1249 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HYDAC International, Bosch, Parker, Pall, Eaton, Schroeder, Swift Filters, Filtrec, STAUFF, Luber-finer (Champion Laboratories), Cleanse Filtration, Xinxiang FeiLiter Equipment, Xufeng Guolv, Wannuo Filter, MP Filtri S.p.A., Hengst Filtration |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |