What is Global Aluminum Medical Oxygen Cylinder Market?

The Global Aluminum Medical Oxygen Cylinder Market is a specialized segment within the broader medical equipment industry, focusing on the production and distribution of oxygen cylinders made from aluminum. These cylinders are crucial for delivering medical-grade oxygen to patients in various healthcare settings, including hospitals, clinics, and home care. Aluminum is preferred over other materials like steel due to its lightweight nature, which makes the cylinders easier to transport and handle, especially in emergency situations. The market is driven by the increasing prevalence of respiratory diseases, the aging population, and the rising demand for home healthcare services. Additionally, technological advancements in cylinder manufacturing and the growing awareness of the benefits of oxygen therapy contribute to market growth. The market is characterized by a diverse range of products, catering to different capacity needs and usage scenarios, from portable options for individual use to larger, stationary units for hospital settings. As healthcare infrastructure continues to expand globally, the demand for efficient and reliable oxygen delivery systems is expected to rise, making the Global Aluminum Medical Oxygen Cylinder Market a vital component of the healthcare industry.

Capacity <10L, Capacity 10 - 20 L, Capacity 20-30 L, Capacity 30-40 L, Capacity≥ 40 L in the Global Aluminum Medical Oxygen Cylinder Market:

In the Global Aluminum Medical Oxygen Cylinder Market, the capacity of cylinders is a critical factor that determines their application and usability. Cylinders with a capacity of less than 10 liters are typically designed for portability and ease of use. These small cylinders are ideal for patients who require oxygen therapy on the go, such as those with chronic obstructive pulmonary disease (COPD) or other respiratory conditions that necessitate continuous oxygen supply. Their lightweight and compact design make them convenient for travel and daily activities, ensuring that patients can maintain their mobility and independence while receiving the necessary oxygen support. Moving up the capacity scale, cylinders with a capacity of 10 to 20 liters are often used in home healthcare settings. These cylinders strike a balance between portability and capacity, providing a sufficient oxygen supply for extended periods without the need for frequent refills. They are suitable for patients who require a steady oxygen flow throughout the day and night, offering a reliable solution for managing respiratory conditions at home. The next category, with a capacity of 20 to 30 liters, is typically used in clinical settings where a higher volume of oxygen is needed. These cylinders are often found in hospitals and clinics, where they can be used to support patients undergoing surgery or those in intensive care units. Their larger capacity ensures that a continuous and uninterrupted oxygen supply is available, which is crucial in critical care situations. Cylinders with a capacity of 30 to 40 liters are generally used in larger healthcare facilities or for specific medical procedures that require a substantial oxygen supply. These cylinders are less portable due to their size and weight, but they provide a high volume of oxygen, making them suitable for use in operating rooms or during long-term treatments. Finally, cylinders with a capacity of 40 liters or more are typically used in industrial or large-scale medical applications. These cylinders are designed to deliver a significant amount of oxygen over an extended period, making them ideal for use in hospitals with high patient turnover or in emergency situations where a large oxygen supply is needed quickly. Overall, the capacity of aluminum medical oxygen cylinders plays a crucial role in determining their application and suitability for different healthcare settings, ensuring that patients receive the appropriate level of oxygen support based on their specific needs.

Portable Oxygen Cylinders, Stationary Oxygen Cylinders in the Global Aluminum Medical Oxygen Cylinder Market:

The usage of Global Aluminum Medical Oxygen Cylinders can be broadly categorized into two main areas: portable oxygen cylinders and stationary oxygen cylinders. Portable oxygen cylinders are designed for mobility and ease of use, making them ideal for patients who require oxygen therapy while on the move. These cylinders are lightweight and compact, allowing patients to carry them easily during daily activities, travel, or outdoor excursions. They are particularly beneficial for individuals with chronic respiratory conditions who need a continuous oxygen supply to maintain their quality of life. Portable cylinders are equipped with user-friendly features such as adjustable flow regulators and comfortable carrying cases, ensuring that patients can manage their oxygen therapy independently. On the other hand, stationary oxygen cylinders are designed for use in fixed locations, such as homes, hospitals, or clinics. These cylinders are larger and provide a higher capacity of oxygen, making them suitable for patients who require a constant and uninterrupted oxygen supply. Stationary cylinders are often used in conjunction with oxygen concentrators or other medical equipment to deliver oxygen therapy to patients with severe respiratory conditions. They are also commonly used in hospital settings to support patients in intensive care units or during surgical procedures. The stationary design ensures that a reliable oxygen supply is always available, which is crucial for patient safety and effective treatment. Both portable and stationary oxygen cylinders play a vital role in the Global Aluminum Medical Oxygen Cylinder Market, catering to the diverse needs of patients and healthcare providers. By offering a range of options, the market ensures that individuals with varying levels of oxygen dependency can access the appropriate support, whether they are at home, in a healthcare facility, or on the go. This versatility and adaptability make aluminum medical oxygen cylinders an essential component of modern healthcare, contributing to improved patient outcomes and enhanced quality of life.

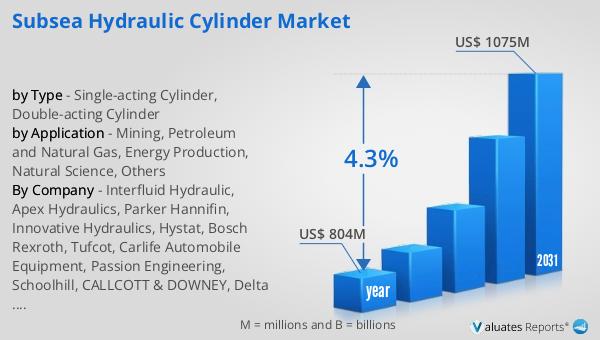

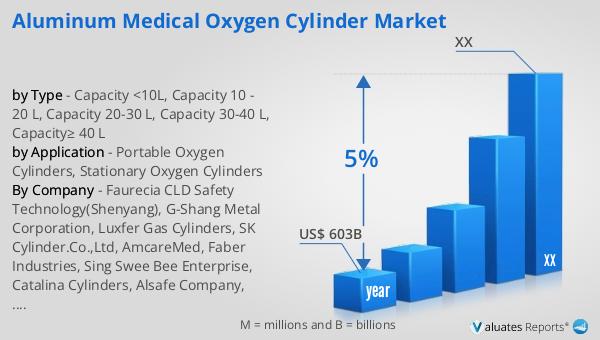

Global Aluminum Medical Oxygen Cylinder Market Outlook:

Our research indicates that the global market for medical devices, which includes the Global Aluminum Medical Oxygen Cylinder Market, is projected to reach an estimated value of $603 billion in 2023. This market is expected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, advancements in medical technology, and the expanding healthcare infrastructure worldwide. As the demand for efficient and reliable medical devices continues to rise, the market is poised for significant expansion. The Global Aluminum Medical Oxygen Cylinder Market, in particular, is benefiting from the growing awareness of the benefits of oxygen therapy and the increasing need for portable and stationary oxygen delivery systems. With the aging population and the rising incidence of respiratory conditions, the demand for medical oxygen cylinders is expected to remain strong. This market outlook highlights the importance of innovation and adaptability in meeting the evolving needs of patients and healthcare providers. As the market continues to grow, companies in the Global Aluminum Medical Oxygen Cylinder Market are likely to focus on developing new products and technologies to enhance patient care and improve outcomes.

| Report Metric | Details |

| Report Name | Aluminum Medical Oxygen Cylinder Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Faurecia CLD Safety Technology(Shenyang), G-Shang Metal Corporation, Luxfer Gas Cylinders, SK Cylinder.Co.,Ltd, AmcareMed, Faber Industries, Sing Swee Bee Enterprise, Catalina Cylinders, Alsafe Company, Orientx Co. Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |