What is Global Aerospace Fasteners Market?

The Global Aerospace Fasteners Market is a crucial segment within the aerospace industry, focusing on the production and distribution of fasteners used in aircraft manufacturing and maintenance. These fasteners are essential components that hold together various parts of an aircraft, ensuring structural integrity and safety. The market encompasses a wide range of products, including bolts, nuts, screws, rivets, and pins, each designed to meet specific requirements of strength, durability, and resistance to environmental factors. The demand for aerospace fasteners is driven by the growth in air travel, advancements in aircraft technology, and the need for lightweight yet strong materials to improve fuel efficiency. As aircraft manufacturers strive to enhance performance and reduce emissions, the role of high-quality fasteners becomes increasingly significant. The market is characterized by continuous innovation, with manufacturers investing in research and development to create fasteners that can withstand extreme conditions and meet stringent regulatory standards. The global aerospace fasteners market is poised for steady growth, supported by the expansion of the commercial aviation sector and the modernization of military fleets worldwide.

Threaded Fasteners, Non-Threaded Fasteners in the Global Aerospace Fasteners Market:

Threaded fasteners and non-threaded fasteners are two primary categories within the Global Aerospace Fasteners Market, each serving distinct functions in aircraft assembly and maintenance. Threaded fasteners, such as bolts and screws, are designed with helical ridges that allow them to be inserted into pre-tapped holes or used with nuts to secure components together. These fasteners are prized for their ability to provide strong, reliable connections that can be easily disassembled and reassembled, making them ideal for applications where maintenance and repairs are frequent. In the aerospace industry, threaded fasteners are used extensively in areas where high strength and precision are required, such as engine assemblies, landing gear, and structural components. The materials used for threaded fasteners in aerospace applications are typically high-grade alloys, including titanium and stainless steel, which offer excellent strength-to-weight ratios and resistance to corrosion and extreme temperatures. Non-threaded fasteners, on the other hand, include rivets, pins, and clips, which are used to join materials without the need for threads. Rivets are particularly common in aircraft construction, where they are used to join sheets of metal in the fuselage and wings. These fasteners are installed by deforming one end to hold the materials together, providing a permanent and robust connection. Non-threaded fasteners are often preferred in applications where vibration resistance and shear strength are critical, as they are less likely to loosen over time compared to their threaded counterparts. The choice between threaded and non-threaded fasteners in aerospace applications depends on various factors, including the specific requirements of the assembly, the materials being joined, and the environmental conditions the aircraft will face. Both types of fasteners play a vital role in ensuring the safety and performance of aircraft, and manufacturers continue to innovate in this field to meet the evolving demands of the aerospace industry. As the market for aerospace fasteners grows, driven by the increasing production of commercial and military aircraft, the development of advanced materials and fastening technologies will remain a key focus for industry players.

Civil, Military in the Global Aerospace Fasteners Market:

The usage of Global Aerospace Fasteners Market products spans across various sectors, with civil and military aviation being the primary areas of application. In the civil aviation sector, aerospace fasteners are integral to the construction and maintenance of commercial aircraft, which are designed to transport passengers and cargo over long distances. The demand for fasteners in this sector is driven by the continuous growth in air travel, the expansion of airline fleets, and the need for regular maintenance and upgrades to ensure safety and efficiency. Civil aircraft require a vast array of fasteners to assemble and secure components such as the fuselage, wings, engines, and interior fittings. The emphasis on lightweight materials to improve fuel efficiency has led to the development of advanced fasteners made from high-strength alloys and composites. These fasteners must meet stringent safety and performance standards, as they play a critical role in maintaining the structural integrity of the aircraft under various operating conditions. In the military aviation sector, aerospace fasteners are used in the production and maintenance of fighter jets, transport aircraft, helicopters, and unmanned aerial vehicles (UAVs). Military aircraft are subject to more demanding performance requirements compared to their civilian counterparts, as they must operate in extreme environments and withstand high levels of stress and vibration. As a result, the fasteners used in military applications are designed to offer superior strength, durability, and resistance to corrosion and fatigue. The modernization of military fleets and the development of advanced defense technologies have further fueled the demand for specialized fasteners that can meet the unique challenges of military aviation. In both civil and military aviation, the reliability and performance of aerospace fasteners are paramount, as any failure can have catastrophic consequences. Manufacturers in the Global Aerospace Fasteners Market are continually innovating to develop products that meet the evolving needs of the aerospace industry, ensuring that aircraft remain safe, efficient, and capable of meeting the demands of modern air travel and defense operations.

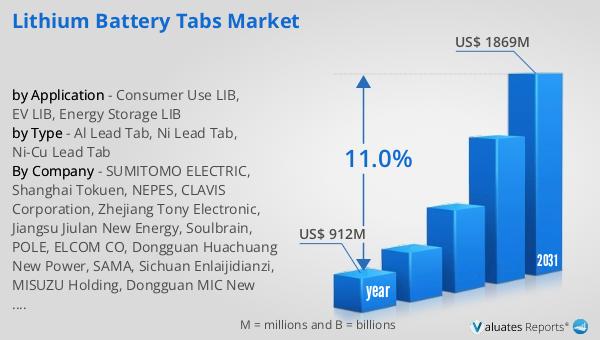

Global Aerospace Fasteners Market Outlook:

In 2024, the global market size for Aerospace Fasteners was valued at approximately US$ 4,353 million, with projections indicating it could reach around US$ 5,552 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2025 to 2031. The market is dominated by the top three manufacturers, who collectively hold about 76% of the market share. Within the product categories, threaded fasteners represent the largest segment, accounting for approximately 83% of the market. This dominance is due to their widespread use in various aerospace applications, where their strength and reliability are crucial. In terms of application, the civil aviation sector is the largest consumer of aerospace fasteners, with a share of about 85%. This is largely driven by the continuous expansion of commercial airline fleets and the increasing demand for air travel globally. The focus on enhancing aircraft performance and safety has led to a growing reliance on high-quality fasteners, which are essential for maintaining the structural integrity and efficiency of modern aircraft. As the aerospace industry continues to evolve, the demand for innovative fastening solutions is expected to rise, supporting the overall growth of the Global Aerospace Fasteners Market.

| Report Metric | Details |

| Report Name | Aerospace Fasteners Market |

| Forecasted market size in 2031 | approximately US$ 5552 million |

| CAGR | 3.6% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Precision Castparts Corp, Howmet Aerospace, LISI Aerospace, AVIC, TriMas Corporation, Paolo Astori, MS Aerospace, NAFCO, Stanley Black & Decker, Ateliers de la Haute Garonne, CASC, Bollhoff, Poggipolini, Gillis Aerospace |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |