What is Global Mill Type Hydraulic Cylinder Market?

The Global Mill Type Hydraulic Cylinder Market is a specialized segment within the broader hydraulic cylinder industry, focusing on robust and durable hydraulic cylinders designed for heavy-duty applications. These cylinders are characterized by their mill-type construction, which involves a welded or bolted design that enhances their strength and durability, making them suitable for challenging environments. They are commonly used in industries such as steel mills, foundries, mining, and oil and gas drilling, where they are exposed to harsh conditions and require high performance and reliability. The market for these cylinders is driven by the demand for efficient and reliable hydraulic systems in heavy industrial applications. As industries continue to expand and modernize, the need for advanced hydraulic solutions grows, contributing to the market's development. The Global Mill Type Hydraulic Cylinder Market is expected to experience steady growth, driven by technological advancements and the increasing adoption of automation in industrial processes. This market is characterized by a diverse range of products tailored to meet specific industry needs, ensuring that businesses can find solutions that align with their operational requirements. The focus on innovation and quality in this market ensures that it remains a critical component of industrial operations worldwide.

Single Rod Cylinder, Dual Rod Cylinder in the Global Mill Type Hydraulic Cylinder Market:

In the Global Mill Type Hydraulic Cylinder Market, Single Rod Cylinders and Dual Rod Cylinders play pivotal roles, each offering unique advantages tailored to specific industrial needs. Single Rod Cylinders are the most common type, featuring a piston rod that extends from one end of the cylinder. This design is straightforward and efficient, making it suitable for a wide range of applications. Single Rod Cylinders are known for their simplicity and cost-effectiveness, providing reliable performance in environments where space is not a constraint. They are often used in applications where the cylinder needs to extend and retract in a linear motion, such as in manufacturing equipment and construction machinery. The single rod design allows for easy maintenance and repair, contributing to its popularity in various industries. On the other hand, Dual Rod Cylinders are designed with two piston rods extending from either end of the cylinder. This configuration offers enhanced stability and resistance to side loads, making them ideal for applications requiring precise control and alignment. Dual Rod Cylinders are commonly used in situations where the load needs to be guided accurately, such as in material handling and robotics. The dual rod design provides additional support and reduces the risk of bending or misalignment, ensuring smooth and efficient operation. In the Global Mill Type Hydraulic Cylinder Market, the choice between Single Rod and Dual Rod Cylinders depends on the specific requirements of the application. Factors such as load capacity, space constraints, and the need for precision play a crucial role in determining the appropriate cylinder type. Manufacturers in this market offer a wide range of options, allowing businesses to select cylinders that best meet their operational needs. The versatility and adaptability of these cylinders make them indispensable in various industrial sectors, contributing to the overall growth and development of the market. As industries continue to evolve and demand more sophisticated hydraulic solutions, the importance of understanding the differences between Single Rod and Dual Rod Cylinders becomes increasingly significant. By choosing the right type of cylinder, businesses can enhance their operational efficiency, reduce downtime, and improve overall productivity. The Global Mill Type Hydraulic Cylinder Market is poised for continued growth as industries seek reliable and efficient hydraulic solutions to meet their evolving needs.

Steel Mmills, Foundries, Mining Applications, Oil Drilling, Gas Drilling, Industrial Machinery Applications, Others in the Global Mill Type Hydraulic Cylinder Market:

The Global Mill Type Hydraulic Cylinder Market finds extensive usage across various industries, each with unique demands and operational challenges. In steel mills, these hydraulic cylinders are crucial for handling heavy loads and ensuring precise control in processes such as rolling, forging, and pressing. The robust construction of mill-type cylinders makes them ideal for the harsh environments of steel mills, where they must withstand high temperatures and pressures. Foundries also rely on these cylinders for tasks such as mold handling and casting, where precision and durability are paramount. In mining applications, mill-type hydraulic cylinders are essential for equipment such as excavators, loaders, and crushers. These cylinders provide the necessary force and control to handle the demanding conditions of mining operations, including heavy loads, abrasive materials, and challenging terrains. The reliability and strength of mill-type cylinders make them indispensable in ensuring the efficiency and safety of mining activities. In the oil and gas industry, these hydraulic cylinders are used in drilling rigs and other equipment, where they must perform reliably under extreme conditions. The ability to withstand high pressures and corrosive environments makes mill-type cylinders a preferred choice for oil and gas applications. Industrial machinery applications also benefit from the use of mill-type hydraulic cylinders, where they provide the necessary force and precision for tasks such as material handling, assembly, and packaging. The versatility of these cylinders allows them to be used in a wide range of machinery, contributing to improved efficiency and productivity. Other industries, such as construction and agriculture, also utilize mill-type hydraulic cylinders for various applications, highlighting their adaptability and importance in modern industrial operations. The Global Mill Type Hydraulic Cylinder Market continues to grow as industries recognize the value of these robust and reliable hydraulic solutions in enhancing their operational capabilities.

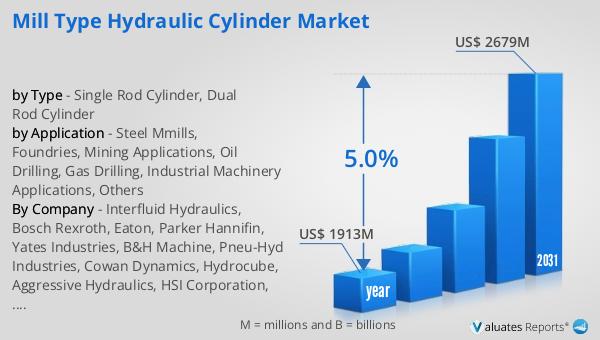

Global Mill Type Hydraulic Cylinder Market Outlook:

The outlook for the Global Mill Type Hydraulic Cylinder Market indicates a promising future, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 1913 million, reflecting its substantial presence in the industrial sector. Looking ahead, the market is projected to expand, reaching an estimated size of US$ 2679 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.0% during the forecast period. The steady increase in market size underscores the rising demand for mill-type hydraulic cylinders across various industries. Factors contributing to this growth include the ongoing industrialization and modernization efforts worldwide, which drive the need for efficient and reliable hydraulic systems. Additionally, technological advancements and the increasing adoption of automation in industrial processes further fuel the demand for these robust hydraulic solutions. As industries continue to evolve and seek innovative ways to enhance productivity and efficiency, the Global Mill Type Hydraulic Cylinder Market is well-positioned to meet these demands. The market's focus on quality, durability, and performance ensures that it remains a critical component of industrial operations, supporting businesses in achieving their operational goals. With a strong growth outlook, the Global Mill Type Hydraulic Cylinder Market is set to play a vital role in the future of industrial hydraulic systems.

| Report Metric | Details |

| Report Name | Mill Type Hydraulic Cylinder Market |

| Accounted market size in year | US$ 1913 million |

| Forecasted market size in 2031 | US$ 2679 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Interfluid Hydraulics, Bosch Rexroth, Eaton, Parker Hannifin, Yates Industries, B&H Machine, Pneu-Hyd Industries, Cowan Dynamics, Hydrocube, Aggressive Hydraulics, HSI Corporation, Hanna Cylinders, Shenzhen Dallast Technology, KCCPR, Lynair, Trident Products, Flutec Hydraulics, Actuant, SMC, Texas Hydraulics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |