What is Global Nitrogen Gas Springs Market?

The Global Nitrogen Gas Springs Market is a dynamic and evolving sector that plays a crucial role in various industries by providing essential components for machinery and equipment. Nitrogen gas springs are devices that use compressed nitrogen gas to exert force, offering a reliable and consistent performance in applications requiring controlled motion and force. These springs are widely used in manufacturing processes, particularly in the automotive and electronics industries, due to their ability to provide precise force control and durability. The market for nitrogen gas springs is driven by the increasing demand for automation and efficiency in production processes, as well as the need for high-performance components that can withstand rigorous operational conditions. As industries continue to advance and seek innovative solutions, the demand for nitrogen gas springs is expected to grow, making it a significant area of interest for manufacturers and investors alike. The market is characterized by a diverse range of products, each designed to meet specific application requirements, and is supported by a robust supply chain that ensures the availability of high-quality components to meet global demand.

Standard Nitrogen Gas Springs, Compact Nitrogen Gas Springs, Super CompactNitrogen Gas Springs, Micro Nitrogen Gas Springs in the Global Nitrogen Gas Springs Market:

Standard Nitrogen Gas Springs are the most commonly used type in the Global Nitrogen Gas Springs Market, known for their versatility and reliability. These springs are designed to provide consistent force and are used in a wide range of applications, from automotive manufacturing to industrial machinery. They are typically larger in size compared to other types and are capable of delivering higher force outputs, making them suitable for heavy-duty applications. Compact Nitrogen Gas Springs, on the other hand, are designed for applications where space is limited. These springs offer a smaller footprint while still providing substantial force, making them ideal for use in compact machinery and equipment. Their design allows for easy integration into existing systems without compromising on performance. Super Compact Nitrogen Gas Springs take this a step further by offering even smaller dimensions, making them perfect for applications where space is at a premium. Despite their small size, these springs are engineered to deliver high force outputs, ensuring they can handle demanding tasks in tight spaces. Micro Nitrogen Gas Springs are the smallest in the range, designed for precision applications where minimal force is required. These springs are often used in delicate electronic equipment and other applications where precise control is essential. Each type of nitrogen gas spring is engineered to meet specific needs, providing manufacturers with a range of options to choose from based on their application requirements. The diversity in product offerings within the Global Nitrogen Gas Springs Market ensures that there is a suitable solution for every application, whether it requires high force, compact size, or precision control. This variety also allows manufacturers to optimize their production processes by selecting the most appropriate type of spring for their specific needs, ultimately enhancing efficiency and performance.

Automotive, Electronics, Others in the Global Nitrogen Gas Springs Market:

The usage of nitrogen gas springs in the automotive industry is extensive, as these components are integral to the manufacturing and assembly processes. In automotive applications, nitrogen gas springs are used in stamping dies, where they provide the necessary force to shape metal parts with precision and consistency. This ensures that each component meets the required specifications and quality standards, contributing to the overall performance and safety of the vehicle. Additionally, nitrogen gas springs are used in suspension systems, where they help absorb shocks and provide a smoother ride. Their ability to deliver consistent force and withstand harsh conditions makes them ideal for use in automotive applications, where reliability and durability are paramount. In the electronics industry, nitrogen gas springs are used in the assembly of electronic components and devices. They provide the necessary force to hold components in place during the assembly process, ensuring that each part is correctly positioned and securely attached. This is particularly important in the production of delicate electronic devices, where precision and accuracy are critical. The use of nitrogen gas springs in electronics manufacturing helps improve efficiency and reduce the risk of damage to sensitive components, ultimately enhancing the quality and reliability of the final product. Beyond automotive and electronics, nitrogen gas springs are used in a variety of other industries, including aerospace, medical devices, and consumer goods. In aerospace applications, they are used in the manufacturing of aircraft components, where they provide the necessary force to shape and assemble parts with precision. In the medical device industry, nitrogen gas springs are used in the production of surgical instruments and equipment, where they help ensure that each component meets the required specifications and quality standards. In consumer goods, nitrogen gas springs are used in the production of household appliances and other products, where they provide the necessary force to assemble and operate components with ease. The versatility and reliability of nitrogen gas springs make them an essential component in a wide range of applications, contributing to the efficiency and performance of manufacturing processes across various industries.

Global Nitrogen Gas Springs Market Outlook:

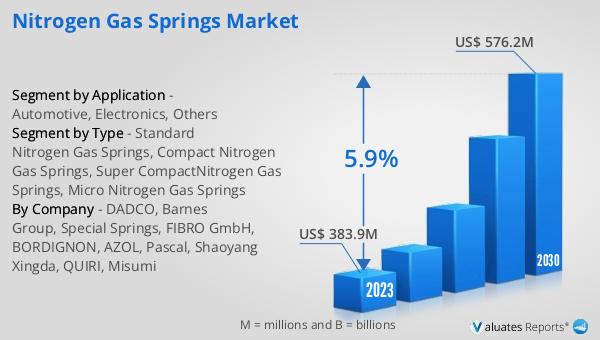

In 2024, the global market size for Nitrogen Gas Springs was valued at approximately US$ 430 million, with projections indicating a growth to around US$ 639 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.9% during the forecast period from 2025 to 2031. The market is dominated by the top five players, who collectively hold a share of about 36%. Among the different product types, Standard Nitrogen Gas Springs represent the largest segment, accounting for approximately 60% of the market share. This dominance is attributed to their widespread use across various industries due to their reliability and versatility. The growth of the Global Nitrogen Gas Springs Market is driven by the increasing demand for automation and efficiency in manufacturing processes, as well as the need for high-performance components that can withstand rigorous operational conditions. As industries continue to advance and seek innovative solutions, the demand for nitrogen gas springs is expected to grow, making it a significant area of interest for manufacturers and investors alike. The market is characterized by a diverse range of products, each designed to meet specific application requirements, and is supported by a robust supply chain that ensures the availability of high-quality components to meet global demand.

| Report Metric | Details |

| Report Name | Nitrogen Gas Springs Market |

| CAGR | 5.9% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | DADCO, Barnes Group, Special Springs, FIBRO GmbH, BORDIGNON, AZOL, Pascal, Shaoyang Xingda, QUIRI, Misumi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |