What is Global Copper Paste Market?

The Global Copper Paste Market is a dynamic and evolving sector that plays a crucial role in various industries. Copper paste is a conductive material used primarily in electronics and solar energy applications. It is composed of finely powdered copper particles mixed with a binding agent, which allows it to be applied as a paste. Once applied, it is typically sintered, or heated, to form a solid conductive layer. This market is driven by the increasing demand for electronic devices and renewable energy solutions, as copper paste is essential for manufacturing components like printed circuit boards (PCBs) and multilayer ceramic capacitors (MLCCs). The market is characterized by technological advancements aimed at improving the efficiency and performance of copper paste, as well as efforts to reduce production costs. Additionally, environmental concerns and the push for sustainable materials are influencing market trends, with companies exploring eco-friendly alternatives and production methods. The global copper paste market is expected to grow steadily, driven by the expanding electronics industry and the rising adoption of solar energy technologies. As industries continue to innovate and adapt to changing consumer demands, the copper paste market will likely see further developments and opportunities.

Low Temperature Sintered, Medium Temperature Sintered, High Temperature Sintered in the Global Copper Paste Market:

In the Global Copper Paste Market, sintering temperatures play a significant role in determining the properties and applications of the paste. Low Temperature Sintered copper paste is designed for applications where heat-sensitive substrates are used. This type of paste is ideal for flexible electronics and certain types of PCBs where high temperatures could damage the substrate. The low sintering temperature allows for the paste to be used in applications that require a gentle thermal process, ensuring that the integrity of the substrate is maintained. Medium Temperature Sintered copper paste strikes a balance between performance and thermal requirements. It is often used in applications where moderate heat resistance is needed, such as in some types of MLCCs and other electronic components that require a stable conductive layer without the risk of substrate damage. This type of paste is versatile and can be used in a variety of electronic applications, providing a reliable conductive path while maintaining the structural integrity of the components. High Temperature Sintered copper paste is used in applications that require excellent thermal and electrical conductivity. This type of paste is suitable for high-performance electronic components and solar cells, where the paste must withstand high temperatures during operation. The high sintering temperature ensures that the copper particles form a dense and robust conductive layer, which is essential for applications that demand high reliability and efficiency. In the global market, High Temperature Sintered copper paste holds the largest market share, reflecting its importance in high-performance applications. Each type of sintered copper paste has its unique advantages and is chosen based on the specific requirements of the application, such as thermal stability, conductivity, and substrate compatibility. As technology advances, the development of new sintering techniques and formulations continues to enhance the performance and applicability of copper paste in various industries.

PCB, MLCC, Others in the Global Copper Paste Market:

The Global Copper Paste Market finds its usage in several key areas, including Printed Circuit Boards (PCBs), Multilayer Ceramic Capacitors (MLCCs), and other applications. In the realm of PCBs, copper paste is used to create conductive pathways that connect different components on the board. The paste is applied to the board and then sintered to form a solid conductive layer, which is crucial for the functionality of the PCB. This application is vital in the electronics industry, as PCBs are the backbone of most electronic devices, from smartphones to computers. The demand for copper paste in PCB manufacturing is driven by the increasing complexity and miniaturization of electronic devices, which require precise and reliable conductive pathways. In MLCCs, copper paste is used to create the internal electrodes that are essential for the capacitor's function. MLCCs are widely used in electronic circuits for their ability to store and release electrical energy efficiently. The use of copper paste in MLCCs is driven by the need for high-performance capacitors that can operate reliably in various conditions. The paste's conductive properties ensure that the capacitors can handle the electrical demands placed on them, making them suitable for a wide range of applications, from consumer electronics to automotive systems. Beyond PCBs and MLCCs, copper paste is also used in other applications, such as solar cells and sensors. In solar cells, copper paste is used to create the conductive grid that collects and transports electrical energy generated by the cell. This application is crucial for the efficiency and performance of solar panels, as the conductive grid must be able to handle the electrical output of the cell without significant losses. In sensors, copper paste is used to create conductive pathways that allow the sensor to detect and transmit signals accurately. The versatility and reliability of copper paste make it an essential material in these applications, contributing to the overall performance and efficiency of the devices. As the demand for advanced electronic devices and renewable energy solutions continues to grow, the usage of copper paste in these areas is expected to expand, driving further innovation and development in the market.

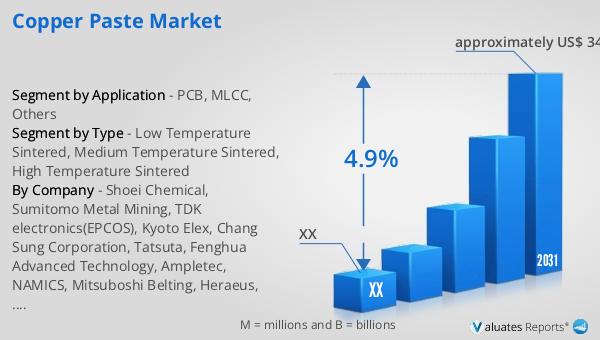

Global Copper Paste Market Outlook:

In 2024, the global market size of Copper Paste was valued at approximately US$ 250 million, with projections indicating it could reach around US$ 348 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.9% during the forecast period from 2025 to 2031. The market is dominated by the top three companies, which collectively hold about 38 percent of the market share. Geographically, Japan stands as the largest market for Copper Paste, commanding a market share of approximately 46%. Following Japan, China and South Korea are significant players, with market shares of 24% and 15%, respectively. When examining product types, High Temperature Sintered copper paste emerges as the largest segment, accounting for roughly 42% of the market share. In terms of application, Multilayer Ceramic Capacitors (MLCCs) represent the largest downstream segment, making up about 49% of the market. This data highlights the significant role that copper paste plays in the electronics industry, particularly in regions with strong technological and manufacturing capabilities. The growth in this market is indicative of the increasing demand for high-performance electronic components and the ongoing advancements in technology that drive the need for reliable and efficient conductive materials.

| Report Metric | Details |

| Report Name | Copper Paste Market |

| Forecasted market size in 2031 | approximately US$ 348 million |

| CAGR | 4.9% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Shoei Chemical, Sumitomo Metal Mining, TDK electronics(EPCOS), Kyoto Elex, Chang Sung Corporation, Tatsuta, Fenghua Advanced Technology, Ampletec, NAMICS, Mitsuboshi Belting, Heraeus, Sinocera, Asahi Chemical, Material Concept |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |