What is Global Gravimetric Feeder (Loss-in-Weight) Market?

The Global Gravimetric Feeder (Loss-in-Weight) Market is a specialized segment within the industrial equipment sector, focusing on devices that precisely measure and control the flow of bulk materials. These feeders are essential in various industries for maintaining accurate material flow rates, ensuring consistent product quality, and optimizing production processes. The term "loss-in-weight" refers to the method these feeders use to measure the material flow: by continuously weighing the feeder and its contents, they can determine the rate at which material is being dispensed. This technology is crucial for applications where precision is paramount, such as in the production of pharmaceuticals, food processing, and chemical manufacturing. The market for these feeders is driven by the increasing demand for automation and precision in industrial processes, as well as the need for efficient material handling solutions. As industries continue to evolve and seek more efficient production methods, the demand for gravimetric feeders is expected to grow, making this market a vital component of the broader industrial equipment landscape.

Single Screw Gravimetric Feeder, Twin Screw Gravimetric Feeder, Others in the Global Gravimetric Feeder (Loss-in-Weight) Market:

Single Screw Gravimetric Feeders are a type of loss-in-weight feeder that utilize a single screw mechanism to control the flow of materials. These feeders are particularly suited for handling free-flowing materials such as granules and pellets. The single screw design allows for a straightforward and cost-effective solution for applications where high precision is not the primary concern. They are commonly used in industries like plastics and food processing, where the material characteristics are consistent and predictable. On the other hand, Twin Screw Gravimetric Feeders are designed to handle more challenging materials, including those that are sticky, cohesive, or have a tendency to bridge. The twin screw mechanism provides a more robust and versatile solution, capable of handling a wider range of material types and flow characteristics. This makes them ideal for applications in the chemical and pharmaceutical industries, where precise control over material flow is critical. The twin screw design also allows for better mixing and blending of materials, which is essential in processes where uniformity is key. In addition to single and twin screw feeders, the Global Gravimetric Feeder (Loss-in-Weight) Market also includes other types of feeders, such as belt feeders and vibratory feeders. Belt feeders are used for applications where a continuous and uniform flow of material is required, such as in mining and construction. They are particularly effective for handling large volumes of material over long distances. Vibratory feeders, on the other hand, are used for applications where gentle handling of materials is necessary, such as in the food and pharmaceutical industries. They use vibration to move materials along a trough, providing a smooth and controlled flow. Each type of feeder within the Global Gravimetric Feeder (Loss-in-Weight) Market is designed to meet specific application requirements, offering a range of solutions for different industries and material handling challenges.

Food & Beverages, Mining & Metallurgy, Pharmaceutical, Construction, Plastics, Chemicals, Others in the Global Gravimetric Feeder (Loss-in-Weight) Market:

The Global Gravimetric Feeder (Loss-in-Weight) Market finds extensive usage across various industries due to its ability to provide precise and consistent material flow control. In the Food & Beverages sector, these feeders are crucial for ensuring the accurate dosing of ingredients, which is essential for maintaining product quality and consistency. They help in automating the production process, reducing human error, and increasing efficiency. In the Mining & Metallurgy industry, gravimetric feeders are used to control the flow of raw materials into processing equipment, ensuring optimal operation and reducing waste. The ability to handle large volumes of material with precision makes them indispensable in this sector. In the Pharmaceutical industry, where precision is of utmost importance, gravimetric feeders are used to ensure the accurate dosing of active ingredients, which is critical for product efficacy and safety. They help in maintaining strict quality control standards and complying with regulatory requirements. In the Construction industry, these feeders are used to control the flow of materials such as cement and aggregates, ensuring consistent mixing and quality of the final product. In the Plastics industry, gravimetric feeders are used to control the flow of raw materials into extrusion and molding equipment, ensuring consistent product quality and reducing material waste. The ability to handle a wide range of material types and flow characteristics makes them ideal for this sector. In the Chemicals industry, gravimetric feeders are used to control the flow of raw materials into reactors and other processing equipment, ensuring optimal reaction conditions and product quality. The ability to handle corrosive and hazardous materials with precision makes them essential in this sector. Overall, the Global Gravimetric Feeder (Loss-in-Weight) Market plays a critical role in various industries, providing solutions for precise and efficient material handling.

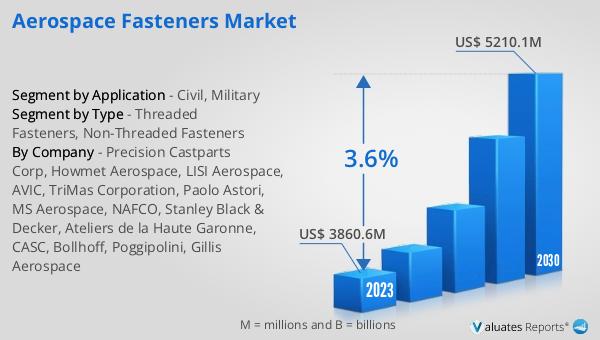

Global Gravimetric Feeder (Loss-in-Weight) Market Outlook:

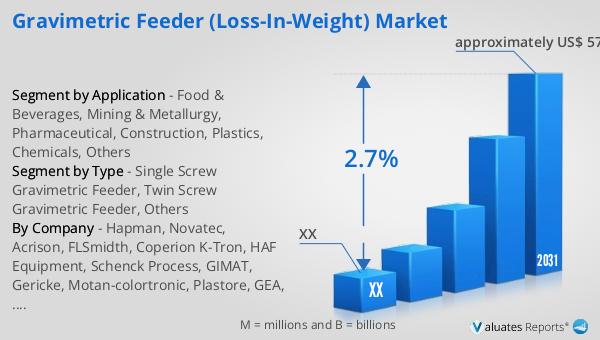

In 2024, the global market size for Gravimetric Feeder (Loss-in-Weight) was valued at approximately US$ 482 million, with projections indicating it could reach around US$ 579 million by 2031, growing at a compound annual growth rate (CAGR) of 2.7% during the forecast period from 2025 to 2031. Within this industry, the top ten manufacturers hold a combined production market share of 26%. Leading the pack are Hapman, Novatec, Acrison, FLSmidth, and Coperion K-Tron, which together account for nearly 31% of the market share. Hapman, with a 6% market share, stands as the leader in the Gravimetric Feeder (Loss-in-Weight) industry. The United States emerges as the largest production region, contributing about 37% to the global production, while Europe follows with approximately 28%. Notably, the plastics sector commands a significant portion of the market, holding a 54% share. This data underscores the importance of the Gravimetric Feeder (Loss-in-Weight) Market in various industrial applications, highlighting its role in enhancing production efficiency and precision across different sectors.

| Report Metric | Details |

| Report Name | Gravimetric Feeder (Loss-in-Weight) Market |

| Forecasted market size in 2031 | approximately US$ 579 million |

| CAGR | 2.7% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hapman, Novatec, Acrison, FLSmidth, Coperion K-Tron, HAF Equipment, Schenck Process, GIMAT, Gericke, Motan-colortronic, Plastore, GEA, Brabender, Sonner, TBMA, Kubota, Tecnetics Industries, MERRICK Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |