What is Global Linear Piezo Stage Market?

The Global Linear Piezo Stage Market is a specialized segment within the broader field of precision motion control systems. Linear piezo stages are devices that utilize piezoelectric materials to produce precise linear movements. These stages are integral in applications requiring high precision and accuracy, such as in semiconductor manufacturing, optics, and nanotechnology. The market for these devices is driven by the increasing demand for miniaturization and precision in various industries. As technology advances, the need for equipment that can operate at micro and nano scales becomes more critical, and linear piezo stages are at the forefront of this demand. They offer advantages such as high resolution, fast response times, and the ability to operate in vacuum environments, making them suitable for a wide range of applications. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the performance and capabilities of these stages to meet the evolving needs of industries. As a result, the Global Linear Piezo Stage Market is poised for growth, driven by technological advancements and the increasing adoption of precision motion control systems across various sectors.

Single Axis, Two Axis, Three Axis in the Global Linear Piezo Stage Market:

In the Global Linear Piezo Stage Market, stages are often categorized based on the number of axes they can control: single-axis, two-axis, and three-axis. Single-axis piezo stages are designed to provide movement along one linear direction. These stages are typically used in applications where precise control of movement in a single direction is required. They are commonly employed in fields such as optics, where they can be used to adjust the position of lenses or mirrors with high precision. Single-axis stages are valued for their simplicity and reliability, making them a popular choice for applications that do not require multi-directional movement. Two-axis piezo stages, on the other hand, offer movement along two perpendicular directions. This capability allows for more complex positioning tasks, such as aligning components in two-dimensional space. Two-axis stages are often used in applications like semiconductor manufacturing, where precise alignment of components is crucial for the production of high-quality devices. These stages provide the flexibility needed to perform intricate positioning tasks, making them an essential tool in industries that require high precision and accuracy. Three-axis piezo stages take this a step further by providing movement along three perpendicular directions. This allows for full three-dimensional positioning, making them ideal for applications that require complex motion control. Three-axis stages are commonly used in fields such as nanotechnology and materials science, where precise control of movement in three dimensions is necessary for tasks like scanning and manipulation of samples. These stages offer the highest level of flexibility and precision, making them indispensable in advanced research and industrial applications. The choice between single-axis, two-axis, and three-axis piezo stages depends on the specific requirements of the application. Factors such as the level of precision needed, the complexity of the positioning task, and the available budget all play a role in determining the most suitable type of stage. As the demand for precision motion control continues to grow, manufacturers are developing increasingly sophisticated piezo stages to meet the diverse needs of various industries. This ongoing innovation is driving the growth of the Global Linear Piezo Stage Market, as more industries recognize the benefits of using these advanced positioning systems.

Medicine, Materials Engineering, Others in the Global Linear Piezo Stage Market:

The Global Linear Piezo Stage Market finds significant applications in various fields, including medicine, materials engineering, and other industries. In the medical field, linear piezo stages are used in applications such as medical imaging and surgical procedures. Their ability to provide precise and controlled movements makes them ideal for tasks that require high accuracy, such as positioning imaging equipment or guiding surgical instruments. In medical imaging, for example, piezo stages can be used to adjust the position of imaging devices with high precision, ensuring that images are captured accurately and consistently. This level of precision is crucial for diagnosing and treating medical conditions effectively. In surgical procedures, piezo stages can be used to guide instruments with high accuracy, reducing the risk of errors and improving patient outcomes. In materials engineering, linear piezo stages are used in applications such as materials testing and analysis. Their ability to provide precise and controlled movements makes them ideal for tasks that require high accuracy, such as positioning samples for testing or analyzing the properties of materials. In materials testing, for example, piezo stages can be used to position samples with high precision, ensuring that tests are conducted accurately and consistently. This level of precision is crucial for obtaining reliable and accurate test results, which are essential for developing new materials and improving existing ones. In other industries, linear piezo stages are used in a wide range of applications, from semiconductor manufacturing to optics and nanotechnology. Their ability to provide precise and controlled movements makes them ideal for tasks that require high accuracy, such as aligning components or manipulating samples. In semiconductor manufacturing, for example, piezo stages can be used to align components with high precision, ensuring that devices are produced accurately and consistently. This level of precision is crucial for producing high-quality semiconductor devices, which are essential for the functioning of modern electronic devices. In optics, piezo stages can be used to adjust the position of lenses or mirrors with high precision, ensuring that optical systems function accurately and efficiently. In nanotechnology, piezo stages can be used to manipulate samples with high precision, enabling researchers to conduct experiments and develop new technologies at the nanoscale. Overall, the Global Linear Piezo Stage Market plays a crucial role in enabling precision and accuracy in a wide range of applications across various industries.

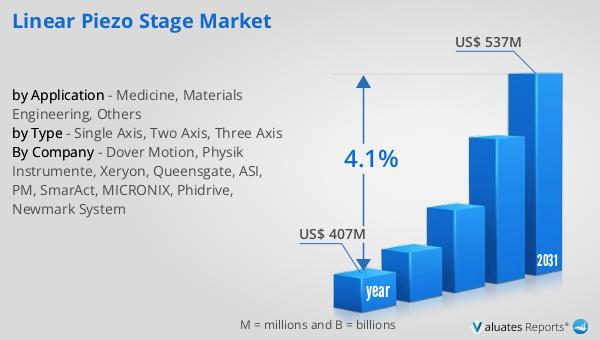

Global Linear Piezo Stage Market Outlook:

The global market for Linear Piezo Stage was valued at $407 million in 2024 and is anticipated to expand to a revised size of $537 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.1% during the forecast period. This growth trajectory underscores the increasing demand for precision motion control systems across various industries. The market's expansion is driven by the need for high precision and accuracy in applications such as semiconductor manufacturing, optics, and nanotechnology. As industries continue to advance technologically, the demand for equipment that can operate at micro and nano scales becomes more critical, and linear piezo stages are at the forefront of this demand. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the performance and capabilities of these stages to meet the evolving needs of industries. This ongoing innovation is driving the growth of the Global Linear Piezo Stage Market, as more industries recognize the benefits of using these advanced positioning systems. The market's growth is also supported by the increasing adoption of precision motion control systems across various sectors, as industries seek to improve efficiency and productivity. As a result, the Global Linear Piezo Stage Market is poised for growth, driven by technological advancements and the increasing adoption of precision motion control systems across various sectors.

| Report Metric | Details |

| Report Name | Linear Piezo Stage Market |

| Accounted market size in year | US$ 407 million |

| Forecasted market size in 2031 | US$ 537 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dover Motion, Physik Instrumente, Xeryon, Queensgate, ASI, PM, SmarAct, MICRONIX, Phidrive, Newmark System |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |