What is Global Industrial Hydraulic Shock Absorber Market?

The Global Industrial Hydraulic Shock Absorber Market is a specialized segment within the broader industrial equipment industry, focusing on devices designed to absorb and dissipate kinetic energy. These shock absorbers are crucial in various industrial applications, where they help to control the movement of machinery, reduce noise, and minimize wear and tear on equipment. By converting kinetic energy into heat, these devices ensure smoother operation and prolong the lifespan of industrial machinery. The market for these shock absorbers is driven by the increasing demand for automation and efficiency in industries such as manufacturing, automotive, and aerospace. As industries continue to evolve, the need for reliable and efficient shock absorption solutions becomes more critical, making this market an essential component of modern industrial operations. The global reach of this market indicates its importance across different regions, with manufacturers continuously innovating to meet the diverse needs of their clients.

Adjustable Shock Absorber, Non-Adjustable Shock Absorber in the Global Industrial Hydraulic Shock Absorber Market:

Adjustable and non-adjustable shock absorbers are two primary types of devices within the Global Industrial Hydraulic Shock Absorber Market, each serving distinct purposes based on their design and functionality. Adjustable shock absorbers offer flexibility in controlling the damping force, allowing users to fine-tune the performance according to specific operational requirements. This adjustability is particularly beneficial in applications where varying loads and speeds are common, such as in automated manufacturing lines or robotics. By enabling precise control over the damping characteristics, adjustable shock absorbers help optimize the performance and longevity of machinery, reducing maintenance costs and downtime. On the other hand, non-adjustable shock absorbers provide a fixed damping force, making them suitable for applications where consistent performance is required. These shock absorbers are often used in environments where the operational conditions remain relatively stable, such as in conveyor systems or packaging machinery. The simplicity of non-adjustable shock absorbers makes them a cost-effective solution for many industrial applications, as they require less maintenance and are easier to install. Both types of shock absorbers play a crucial role in enhancing the efficiency and reliability of industrial operations, contributing to the overall productivity and safety of the workplace. As industries continue to advance, the demand for both adjustable and non-adjustable shock absorbers is expected to grow, driven by the need for more sophisticated and efficient machinery. Manufacturers in this market are continually innovating to develop shock absorbers that meet the evolving needs of their customers, offering solutions that are both effective and economical. The choice between adjustable and non-adjustable shock absorbers ultimately depends on the specific requirements of the application, with each type offering unique advantages that cater to different operational needs.

Metalworking, Factory Automation, Material Handling & Packaging, Pharmaceutical & Medical, Others in the Global Industrial Hydraulic Shock Absorber Market:

The Global Industrial Hydraulic Shock Absorber Market finds extensive usage across various sectors, including metalworking, factory automation, material handling and packaging, pharmaceutical and medical, and others. In the metalworking industry, hydraulic shock absorbers are essential for controlling the movement of heavy machinery and tools, ensuring precision and reducing the risk of damage to both the equipment and the workpiece. By absorbing the kinetic energy generated during metal cutting, forming, or stamping processes, these shock absorbers help maintain the accuracy and quality of the finished products. In factory automation, hydraulic shock absorbers play a critical role in enhancing the efficiency and reliability of automated systems. They are used to control the motion of robotic arms, conveyor belts, and other automated equipment, minimizing vibrations and ensuring smooth operation. This not only improves the performance of the machinery but also extends its lifespan, reducing maintenance costs and downtime. In material handling and packaging, hydraulic shock absorbers are used to protect delicate products from damage during transportation and handling. By absorbing the shocks and vibrations that occur during the movement of goods, these devices help ensure that products reach their destination in perfect condition. In the pharmaceutical and medical industries, hydraulic shock absorbers are used in various equipment, such as centrifuges, to control vibrations and ensure precise operation. This is crucial in maintaining the accuracy and reliability of medical tests and procedures. Overall, the Global Industrial Hydraulic Shock Absorber Market plays a vital role in enhancing the performance and reliability of machinery across different sectors, contributing to increased productivity and safety.

Global Industrial Hydraulic Shock Absorber Market Outlook:

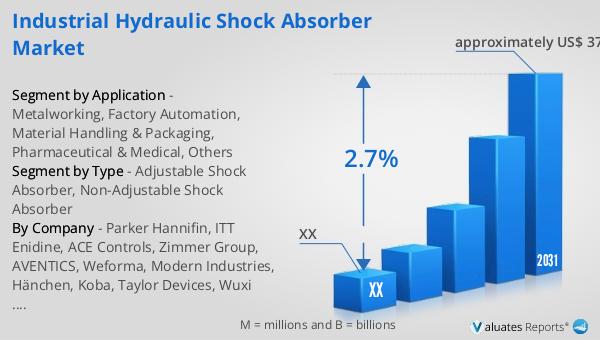

In 2024, the global market size for Industrial Hydraulic Shock Absorbers was valued at approximately US$ 312 million. It is projected to grow to around US$ 375 million by 2031, with a compound annual growth rate (CAGR) of 2.7% during the forecast period from 2025 to 2031. This growth reflects the increasing demand for efficient shock absorption solutions across various industries. Leading the market are prominent players such as Parker Hannifin, ITT Enidine, ACE Controls, and Zimmer Group, which collectively hold about 52% of the market share. These companies are at the forefront of innovation, continuously developing advanced shock absorbers to meet the evolving needs of their customers. The market's steady growth is driven by the rising adoption of automation and the need for reliable and efficient machinery in industries such as manufacturing, automotive, and aerospace. As the market continues to expand, manufacturers are focusing on enhancing the performance and durability of their products, offering solutions that cater to the diverse requirements of their clients. The competitive landscape of the Global Industrial Hydraulic Shock Absorber Market is characterized by ongoing innovation and strategic partnerships, as companies strive to maintain their market position and capitalize on emerging opportunities.

| Report Metric | Details |

| Report Name | Industrial Hydraulic Shock Absorber Market |

| Forecasted market size in 2031 | approximately US$ 375 million |

| CAGR | 2.7% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Parker Hannifin, ITT Enidine, ACE Controls, Zimmer Group, AVENTICS, Weforma, Modern Industries, Hänchen, Koba, Taylor Devices, Wuxi BDC, IZMAC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |