What is Global Heavy Duty Hydraulic Cylinder Market?

The Global Heavy Duty Hydraulic Cylinder Market is a significant segment within the broader hydraulic equipment industry, focusing on the production and distribution of robust hydraulic cylinders designed to handle high-pressure applications. These cylinders are essential components in various industrial and mobile applications, providing the necessary force to move, lift, or press heavy loads. The market encompasses a wide range of products, including single-acting and double-acting cylinders, each tailored to specific operational needs. Heavy duty hydraulic cylinders are crucial in industries such as construction, manufacturing, and mining, where they are used in equipment like excavators, cranes, and industrial presses. The market is driven by the increasing demand for efficient and reliable machinery capable of performing under extreme conditions. Technological advancements and innovations in materials and design have further propelled the market, offering enhanced durability and performance. As industries continue to expand and modernize, the demand for heavy duty hydraulic cylinders is expected to grow, reflecting their indispensable role in facilitating heavy-duty operations across the globe.

Single-acting Cylinder, Double-acting Cylinder in the Global Heavy Duty Hydraulic Cylinder Market:

In the realm of the Global Heavy Duty Hydraulic Cylinder Market, single-acting and double-acting cylinders play pivotal roles, each offering unique functionalities tailored to specific industrial needs. Single-acting cylinders are designed to perform work in one direction, utilizing hydraulic pressure to extend the piston and relying on an external force, such as a spring or gravity, to retract it. This simplicity in design makes single-acting cylinders cost-effective and easy to maintain, making them ideal for applications where the load can assist in the return stroke, such as in lifting operations or in machinery where gravity can aid in retraction. These cylinders are commonly used in applications like dump trucks, jacks, and presses, where the primary requirement is to lift or push a load in one direction. On the other hand, double-acting cylinders are engineered to perform work in both directions, using hydraulic pressure to extend and retract the piston. This design provides greater control and precision, making double-acting cylinders suitable for applications requiring consistent force and movement in both directions. They are widely used in construction equipment, manufacturing machinery, and other industrial applications where precise control over movement is essential. The ability to exert force in both directions allows for more complex operations, such as in robotic arms, where precise positioning and movement are crucial. The choice between single-acting and double-acting cylinders in the Global Heavy Duty Hydraulic Cylinder Market often depends on the specific requirements of the application. Factors such as the load to be moved, the direction of movement, and the need for precision and control play a significant role in determining the appropriate type of cylinder. While single-acting cylinders offer simplicity and cost-effectiveness, double-acting cylinders provide versatility and precision, catering to a broader range of industrial applications. Technological advancements have further enhanced the capabilities of both single-acting and double-acting cylinders. Innovations in materials, such as the use of high-strength alloys and advanced sealing technologies, have improved the durability and performance of these cylinders, allowing them to withstand higher pressures and more demanding conditions. Additionally, advancements in hydraulic systems, such as the integration of electronic controls and sensors, have enabled more precise control and monitoring of cylinder operations, enhancing their efficiency and reliability. In conclusion, single-acting and double-acting cylinders are integral components of the Global Heavy Duty Hydraulic Cylinder Market, each offering distinct advantages tailored to specific industrial needs. The choice between the two depends on various factors, including the nature of the application, the required level of control and precision, and the operational environment. As industries continue to evolve and demand more efficient and reliable machinery, the role of these cylinders in facilitating heavy-duty operations remains crucial, driving innovation and growth in the market.

Construction Equipment, Construction Machinery, Manufacturing, Others in the Global Heavy Duty Hydraulic Cylinder Market:

The Global Heavy Duty Hydraulic Cylinder Market finds extensive usage across various sectors, including construction equipment, construction machinery, manufacturing, and other industries, each benefiting from the unique capabilities of hydraulic cylinders. In the construction equipment sector, heavy duty hydraulic cylinders are indispensable components in machinery such as excavators, loaders, and bulldozers. These cylinders provide the necessary force to lift, push, and move heavy loads, enabling construction equipment to perform tasks such as digging, lifting, and grading with precision and efficiency. The robustness and reliability of hydraulic cylinders make them ideal for the demanding conditions of construction sites, where equipment must operate continuously and withstand harsh environments. In construction machinery, hydraulic cylinders play a crucial role in the operation of cranes, concrete pumps, and other specialized equipment. These cylinders enable precise control over the movement and positioning of heavy loads, ensuring safety and efficiency in construction operations. The ability to exert force in both directions, as seen in double-acting cylinders, allows for more complex operations, such as the precise placement of materials and components in construction projects. The versatility and adaptability of hydraulic cylinders make them essential components in modern construction machinery, contributing to the efficiency and productivity of construction projects. The manufacturing sector also relies heavily on the Global Heavy Duty Hydraulic Cylinder Market, utilizing these cylinders in various machinery and equipment. Hydraulic cylinders are used in presses, injection molding machines, and other manufacturing equipment, providing the force needed to shape, form, and assemble products. The precision and control offered by hydraulic cylinders enable manufacturers to produce high-quality products with consistency and efficiency. The durability and reliability of these cylinders ensure that manufacturing operations can run smoothly and continuously, minimizing downtime and maximizing productivity. Beyond construction and manufacturing, the Global Heavy Duty Hydraulic Cylinder Market serves a wide range of other industries, including mining, agriculture, and transportation. In mining, hydraulic cylinders are used in equipment such as drills, loaders, and haul trucks, providing the force needed to extract and transport materials. In agriculture, these cylinders are used in machinery such as tractors and harvesters, enabling efficient and precise operations in planting, harvesting, and processing crops. In the transportation sector, hydraulic cylinders are used in vehicles such as trucks and buses, providing the force needed for braking, steering, and suspension systems. In summary, the Global Heavy Duty Hydraulic Cylinder Market plays a vital role in various industries, providing the force and precision needed for a wide range of applications. The versatility and adaptability of hydraulic cylinders make them essential components in modern machinery and equipment, contributing to the efficiency, productivity, and safety of operations across different sectors. As industries continue to evolve and demand more efficient and reliable machinery, the role of hydraulic cylinders in facilitating heavy-duty operations remains crucial, driving innovation and growth in the market.

Global Heavy Duty Hydraulic Cylinder Market Outlook:

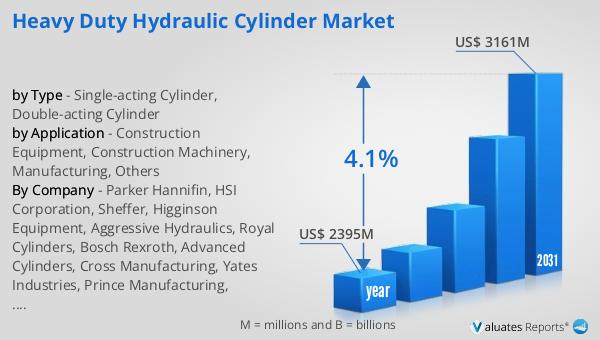

The global market for Heavy Duty Hydraulic Cylinders was valued at approximately $2,395 million in 2024, and it is anticipated to expand to a revised size of around $3,161 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.1% over the forecast period. This upward trend in market value underscores the increasing demand for heavy duty hydraulic cylinders across various industries, driven by the need for efficient and reliable machinery capable of performing under extreme conditions. The market's growth is fueled by advancements in technology and materials, which have enhanced the performance and durability of hydraulic cylinders, making them indispensable components in modern industrial and mobile applications. The projected growth in the market reflects the expanding industrial landscape and the continuous modernization of machinery and equipment. As industries such as construction, manufacturing, and mining continue to evolve, the demand for heavy duty hydraulic cylinders is expected to rise, driven by the need for machinery that can handle high-pressure applications with precision and efficiency. The market's growth is also supported by the increasing adoption of hydraulic systems in emerging economies, where industrialization and infrastructure development are on the rise. In conclusion, the Global Heavy Duty Hydraulic Cylinder Market is poised for significant growth, driven by the increasing demand for efficient and reliable machinery across various industries. The market's expansion reflects the critical role of hydraulic cylinders in facilitating heavy-duty operations, underscoring their importance in the modern industrial landscape. As technological advancements continue to enhance the capabilities of hydraulic cylinders, the market is expected to witness sustained growth, offering opportunities for innovation and development in the years to come.

| Report Metric | Details |

| Report Name | Heavy Duty Hydraulic Cylinder Market |

| Accounted market size in year | US$ 2395 million |

| Forecasted market size in 2031 | US$ 3161 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Parker Hannifin, HSI Corporation, Sheffer, Higginson Equipment, Aggressive Hydraulics, Royal Cylinders, Bosch Rexroth, Advanced Cylinders, Cross Manufacturing, Yates Industries, Prince Manufacturing, Magister Hydraulics, Milwaukee Cylinder, Orione Hydropower, RAM Industries, Takken, PTE Hydraulics, Hydra-Capsule, Hanna Cylinders, Interfluid Hydraulics, Simplex, Bimba, Yueqing Zongjiu Machinery, HDM, Texas Hydraulics, Shenzhen Dallast Technology, Zhejiang Handa Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |