What is Global Inductive Eddy Current Sensors Market?

The Global Inductive Eddy Current Sensors Market is a specialized segment within the broader sensor market, focusing on devices that utilize the principles of electromagnetic induction to detect and measure changes in conductive materials. These sensors are highly valued for their precision and reliability in non-contact measurement applications. They work by generating an alternating magnetic field, which induces eddy currents in a conductive target. The interaction between these currents and the sensor's magnetic field allows for the detection of changes in position, displacement, or material properties. This technology is particularly useful in environments where traditional contact-based sensors might fail due to wear and tear or contamination. Industries such as aerospace, automotive, and manufacturing rely heavily on these sensors for quality control, process monitoring, and automation. The market is driven by the increasing demand for automation and precision in industrial processes, as well as advancements in sensor technology that enhance performance and reduce costs. As industries continue to evolve towards more automated and precise operations, the demand for inductive eddy current sensors is expected to grow, making it a dynamic and promising market segment.

Split Type, Integrated Type in the Global Inductive Eddy Current Sensors Market:

The Global Inductive Eddy Current Sensors Market can be broadly categorized into two types: Split Type and Integrated Type sensors. Split Type sensors consist of separate components for the sensor head and the electronics, connected by a cable. This configuration offers flexibility in installation, allowing the sensor head to be placed in tight or challenging environments while keeping the electronics in a more accessible location. This separation is particularly advantageous in high-temperature or high-vibration environments, where the electronics might be susceptible to damage. Split Type sensors are often used in applications where space constraints or environmental conditions necessitate a more adaptable setup. On the other hand, Integrated Type sensors combine the sensor head and electronics into a single unit. This design simplifies installation and reduces the potential for signal loss or interference, as there are no connecting cables between the sensor head and the electronics. Integrated Type sensors are typically more compact and easier to install, making them suitable for applications where space is limited, and environmental conditions are less extreme. They are often used in standard industrial applications where ease of installation and maintenance are priorities. Both Split Type and Integrated Type sensors have their unique advantages and are chosen based on the specific requirements of the application. The choice between these two types often depends on factors such as the operating environment, space constraints, and the level of precision required. As the demand for more sophisticated and reliable sensing solutions grows, manufacturers are continually innovating to enhance the performance and versatility of both Split Type and Integrated Type inductive eddy current sensors. This ongoing innovation is crucial in meeting the diverse needs of industries ranging from aerospace to automotive, where precision and reliability are paramount. The market for these sensors is characterized by a high degree of customization, with manufacturers offering a wide range of options to suit different applications. This customization includes variations in sensor size, measurement range, and environmental resistance, allowing users to select the most appropriate sensor for their specific needs. As industries continue to push the boundaries of automation and precision, the demand for both Split Type and Integrated Type inductive eddy current sensors is expected to grow, driving further advancements in sensor technology and expanding the market.

Aerospace, Automobile, Electric Power, Petroleum and Chemical, Others in the Global Inductive Eddy Current Sensors Market:

Inductive eddy current sensors are widely used across various industries due to their ability to provide precise, non-contact measurements. In the aerospace industry, these sensors are crucial for ensuring the safety and reliability of aircraft components. They are used to detect cracks, measure material thickness, and monitor the position of moving parts, all of which are essential for maintaining the structural integrity of aircraft. The ability to perform these measurements without direct contact makes eddy current sensors ideal for use in the harsh environments often encountered in aerospace applications. In the automotive industry, inductive eddy current sensors play a vital role in quality control and process monitoring. They are used to measure the thickness of coatings, detect defects in metal parts, and monitor the position of components during assembly. This ensures that vehicles meet stringent safety and performance standards. The sensors' non-contact nature allows for continuous monitoring without interrupting the manufacturing process, improving efficiency and reducing downtime. In the electric power industry, these sensors are used to monitor the condition of critical components such as turbines and generators. By detecting changes in material properties or component positions, they help prevent failures and extend the lifespan of equipment. This is particularly important in power plants, where equipment reliability is crucial for maintaining a stable power supply. In the petroleum and chemical industries, inductive eddy current sensors are used to monitor the condition of pipelines and storage tanks. They can detect corrosion, measure material thickness, and monitor the position of valves and other components. This helps prevent leaks and ensures the safe and efficient operation of facilities. The sensors' ability to operate in harsh environments makes them well-suited for use in these industries, where exposure to chemicals and extreme temperatures is common. Beyond these specific industries, inductive eddy current sensors are used in a wide range of other applications, from manufacturing and robotics to research and development. Their versatility and reliability make them an essential tool for any industry that requires precise, non-contact measurements. As technology continues to advance, the range of applications for these sensors is likely to expand, further driving demand in the global market.

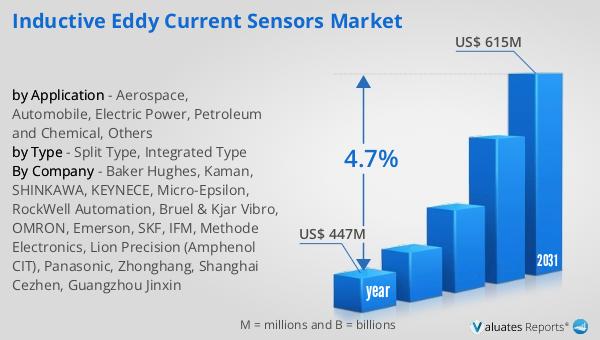

Global Inductive Eddy Current Sensors Market Outlook:

The outlook for the Global Inductive Eddy Current Sensors Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately $447 million. By 2031, it is expected to reach a revised size of $615 million, reflecting a compound annual growth rate (CAGR) of 4.7% during the forecast period. This growth is driven by several factors, including the increasing demand for automation and precision in industrial processes, advancements in sensor technology, and the expanding range of applications for these sensors across various industries. As industries continue to evolve and adopt more sophisticated technologies, the need for reliable and accurate sensing solutions is becoming increasingly important. Inductive eddy current sensors, with their ability to provide precise, non-contact measurements, are well-positioned to meet this demand. The market is characterized by a high degree of innovation, with manufacturers continually developing new and improved sensor solutions to meet the diverse needs of their customers. This ongoing innovation is crucial in maintaining the competitiveness of the market and ensuring that it continues to grow in the coming years. As the market expands, it is likely to attract new entrants, further driving competition and innovation. Overall, the Global Inductive Eddy Current Sensors Market is poised for significant growth, offering numerous opportunities for manufacturers and users alike.

| Report Metric | Details |

| Report Name | Inductive Eddy Current Sensors Market |

| Accounted market size in year | US$ 447 million |

| Forecasted market size in 2031 | US$ 615 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Baker Hughes, Kaman, SHINKAWA, KEYNECE, Micro-Epsilon, RockWell Automation, Bruel & Kjar Vibro, OMRON, Emerson, SKF, IFM, Methode Electronics, Lion Precision (Amphenol CIT), Panasonic, Zhonghang, Shanghai Cezhen, Guangzhou Jinxin |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |