What is Global Multi-Stage Cylinder Market?

The Global Multi-Stage Cylinder Market is a significant segment within the broader hydraulic cylinder industry, characterized by its specialized design and functionality. Multi-stage cylinders, also known as telescopic cylinders, are engineered to provide an extended reach and compact retraction, making them ideal for applications where space is limited but a long stroke is required. These cylinders are composed of multiple stages or sleeves that nest within each other, allowing for a longer extension than a single-stage cylinder of the same retracted length. This unique design makes them highly versatile and efficient for various industrial applications. The market for these cylinders is driven by their widespread use in industries such as construction, mining, agriculture, marine, and oil and gas, where heavy lifting and precise control are paramount. As industries continue to demand more efficient and space-saving solutions, the global multi-stage cylinder market is poised for growth, driven by technological advancements and the increasing need for robust and reliable hydraulic systems. The market's expansion is also supported by the growing trend towards automation and the need for equipment that can perform complex tasks with precision and efficiency.

Single-acting Cylinder, Double-acting Cylinder in the Global Multi-Stage Cylinder Market:

In the realm of hydraulic systems, single-acting and double-acting cylinders play crucial roles, each with distinct functionalities and applications within the Global Multi-Stage Cylinder Market. Single-acting cylinders are designed to perform work in one direction only, using hydraulic pressure to extend the piston and relying on an external force, such as a spring or gravity, to retract it. This simplicity makes them cost-effective and easy to maintain, ideal for applications where the load can assist in the retraction process. They are commonly used in applications like clamping, positioning, and lifting where the return stroke is not critical or can be achieved through external means. On the other hand, double-acting cylinders are more versatile, capable of exerting force in both extending and retracting directions. This is achieved by applying hydraulic pressure alternately to both sides of the piston, allowing for precise control over the movement and positioning of the load. Double-acting cylinders are essential in applications where controlled retraction is necessary, such as in industrial automation, robotics, and heavy machinery. They offer greater flexibility and efficiency, making them suitable for complex tasks that require bidirectional movement. In the context of the Global Multi-Stage Cylinder Market, both single-acting and double-acting cylinders are integral, with their usage determined by the specific requirements of the application. The choice between the two often depends on factors such as the nature of the task, the load involved, and the desired level of control and precision. As industries continue to evolve and demand more sophisticated hydraulic solutions, the role of these cylinders becomes increasingly important, driving innovation and development within the market. The ongoing advancements in materials and technology further enhance the performance and reliability of both single-acting and double-acting cylinders, ensuring they meet the rigorous demands of modern industrial applications.

Construction, Mining, Agriculture, Marine, Oil and Gas, Others in the Global Multi-Stage Cylinder Market:

The Global Multi-Stage Cylinder Market finds extensive usage across various sectors, each benefiting from the unique capabilities of these hydraulic systems. In the construction industry, multi-stage cylinders are indispensable for heavy lifting and precise control of construction equipment such as cranes, excavators, and loaders. Their ability to extend and retract efficiently allows for the smooth operation of machinery in confined spaces, enhancing productivity and safety on construction sites. In the mining sector, these cylinders are crucial for operating large-scale equipment used in excavation and material handling. The harsh and demanding environment of mining operations requires robust and reliable hydraulic systems, and multi-stage cylinders deliver the necessary power and durability to withstand such conditions. Agriculture also benefits significantly from the use of multi-stage cylinders, particularly in machinery like tractors, harvesters, and plows. These cylinders enable efficient operation of agricultural equipment, facilitating tasks such as lifting, tilting, and steering, which are essential for modern farming practices. In the marine industry, multi-stage cylinders are used in various applications, including steering systems, deck machinery, and cargo handling equipment. Their ability to provide precise control and withstand harsh marine conditions makes them ideal for use in ships and offshore platforms. The oil and gas sector relies heavily on multi-stage cylinders for drilling, lifting, and positioning equipment. The demanding nature of oil and gas operations requires hydraulic systems that can deliver high performance and reliability, and multi-stage cylinders meet these requirements with their robust design and efficient operation. Beyond these industries, multi-stage cylinders are also used in other sectors such as aerospace, automotive, and manufacturing, where precise control and efficient operation are critical. The versatility and adaptability of multi-stage cylinders make them a valuable asset in any industry that requires reliable and efficient hydraulic solutions. As technology continues to advance, the applications of multi-stage cylinders are expected to expand further, driving growth and innovation in the market.

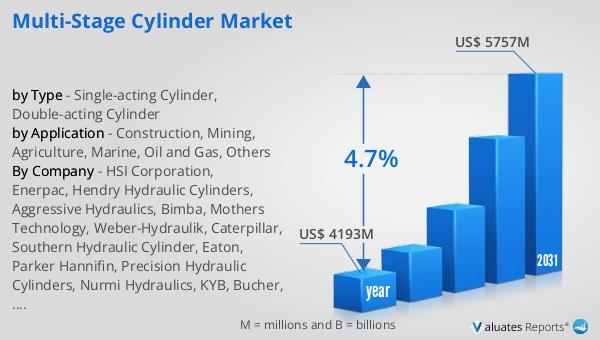

Global Multi-Stage Cylinder Market Outlook:

The global market for multi-stage cylinders was valued at approximately $4,193 million in 2024, reflecting its significant role in various industrial applications. This market is projected to grow steadily, reaching an estimated size of $5,757 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.7% over the forecast period. The steady increase in market size underscores the rising demand for efficient and versatile hydraulic solutions across multiple industries. The expansion of the market is driven by the continuous advancements in technology and the increasing need for equipment that can perform complex tasks with precision and efficiency. As industries such as construction, mining, agriculture, marine, and oil and gas continue to evolve, the demand for multi-stage cylinders is expected to rise, contributing to the market's growth. The projected growth also highlights the importance of innovation and development within the industry, as manufacturers strive to meet the changing needs of their customers. The global multi-stage cylinder market is poised for continued expansion, driven by the increasing demand for reliable and efficient hydraulic systems in various industrial applications.

| Report Metric | Details |

| Report Name | Multi-Stage Cylinder Market |

| Accounted market size in year | US$ 4193 million |

| Forecasted market size in 2031 | US$ 5757 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HSI Corporation, Enerpac, Hendry Hydraulic Cylinders, Aggressive Hydraulics, Bimba, Mothers Technology, Weber-Hydraulik, Caterpillar, Southern Hydraulic Cylinder, Eaton, Parker Hannifin, Precision Hydraulic Cylinders, Nurmi Hydraulics, KYB, Bucher, Herbert Hanchen, Komatsu, Bosch, RHK, Interfluid Hydraulics, Pneumatic Cylinders & Couplers, Delta Hydraulics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |