What is Global Medical Facility Door Closer Market?

The Global Medical Facility Door Closer Market is a specialized segment within the broader architectural hardware industry, focusing on the production and distribution of door closers specifically designed for medical facilities. These door closers are essential components in healthcare environments, ensuring that doors close automatically and securely, which is crucial for maintaining hygiene, privacy, and safety. In medical settings, where the flow of people is constant and the need for controlled environments is critical, door closers help in minimizing the spread of infections by ensuring doors are not left open inadvertently. They also contribute to energy efficiency by maintaining the internal climate of a facility. The market for these products is driven by the increasing number of healthcare facilities worldwide, advancements in door closer technology, and stringent regulations regarding safety and accessibility in medical environments. As healthcare infrastructure continues to expand globally, the demand for reliable and efficient door closers in medical facilities is expected to grow, making this market a vital component of the healthcare industry's operational framework.

Standard, Concealed in Door, Concealed in Frame, Others in the Global Medical Facility Door Closer Market:

The Global Medical Facility Door Closer Market is categorized into several types based on their installation and operational mechanisms, including Standard, Concealed in Door, Concealed in Frame, and Others. Standard door closers are the most commonly used type, typically mounted on the surface of the door or frame. They are visible and easily accessible for maintenance, making them a popular choice for many healthcare facilities. These closers are known for their durability and ease of installation, providing a reliable solution for ensuring doors close securely. Concealed in Door closers, as the name suggests, are installed within the door itself. This type of closer is preferred in settings where aesthetics are important, as they are hidden from view and do not interfere with the door's appearance. They offer a sleek and modern look while providing the same functionality as standard closers. Concealed in Frame closers are installed within the door frame, offering a similar aesthetic advantage as concealed in door closers. They are ideal for facilities that require a clean and unobtrusive appearance, as they do not alter the door's design. These closers are often used in high-end medical facilities where design and functionality are equally important. The "Others" category includes specialized door closers that may have unique features or are designed for specific applications. This can include electromagnetic door closers, which are used in areas where doors need to remain open for extended periods but must close automatically in case of an emergency, such as a fire. These closers are often integrated with fire alarm systems to ensure safety compliance. Each type of door closer serves a specific purpose and is chosen based on the requirements of the medical facility, taking into consideration factors such as door weight, frequency of use, and environmental conditions. The choice of door closer can significantly impact the efficiency and safety of a healthcare facility, making it a critical decision for facility managers and architects. As technology advances, the market continues to see innovations in door closer design, offering enhanced features such as adjustable closing speeds, delayed action, and improved energy efficiency. These advancements are driven by the need for more sophisticated solutions that meet the evolving demands of modern healthcare environments.

Hospital, Clinic, Others in the Global Medical Facility Door Closer Market:

The usage of door closers in the Global Medical Facility Door Closer Market is crucial across various areas such as hospitals, clinics, and other healthcare facilities. In hospitals, door closers play a vital role in maintaining the operational efficiency and safety of the environment. They ensure that doors close automatically, which is essential for controlling the spread of infections and maintaining privacy for patients. In areas like operating rooms, intensive care units, and isolation wards, door closers help in maintaining a controlled environment by ensuring that doors are not left open, which could compromise the sterile conditions required in these settings. Clinics, which often have a high turnover of patients, also benefit from the use of door closers. They help in managing the flow of patients and staff, ensuring that doors close securely after each use. This is particularly important in clinics that handle sensitive medical procedures or have areas that require restricted access. Door closers also contribute to the overall energy efficiency of the facility by preventing drafts and maintaining the internal climate. In other healthcare facilities, such as nursing homes and rehabilitation centers, door closers are used to enhance the safety and accessibility of the environment. They ensure that doors close gently and securely, reducing the risk of accidents or injuries. This is particularly important in facilities that cater to elderly or disabled individuals, where ease of access and safety are paramount. Additionally, door closers in these settings can be equipped with features such as delayed action, which allows individuals more time to pass through the door before it closes. This is especially beneficial for those with mobility challenges. Overall, the use of door closers in medical facilities is an integral part of ensuring a safe, efficient, and comfortable environment for patients, staff, and visitors. As healthcare facilities continue to evolve and expand, the demand for advanced door closer solutions that meet the specific needs of these environments is expected to grow.

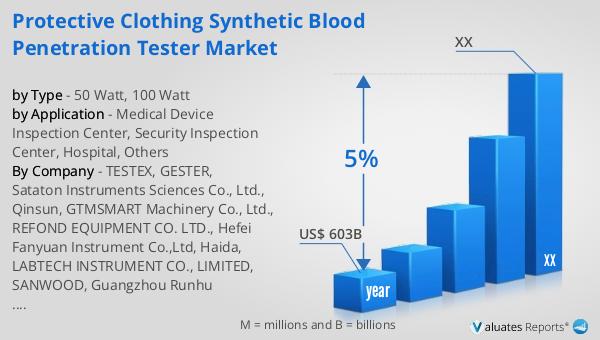

Global Medical Facility Door Closer Market Outlook:

Our research indicates that the global market for medical devices, which includes the Global Medical Facility Door Closer Market, is projected to reach approximately US$ 603 billion in 2023. This market is anticipated to experience a steady growth rate, with a compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing demand for healthcare services, advancements in medical technology, and the expansion of healthcare infrastructure worldwide. As the global population continues to grow and age, the need for medical facilities and the equipment that supports them, such as door closers, is expected to rise. Additionally, the emphasis on improving healthcare accessibility and safety standards is contributing to the demand for high-quality door closers that meet the specific requirements of medical environments. The market's growth is also supported by the ongoing development of innovative door closer solutions that offer enhanced functionality, energy efficiency, and compliance with safety regulations. As healthcare facilities strive to provide better patient care and operational efficiency, the role of door closers in maintaining a secure and controlled environment becomes increasingly important. This market outlook highlights the significant opportunities for growth and innovation within the Global Medical Facility Door Closer Market, as it continues to evolve in response to the changing needs of the healthcare industry.

| Report Metric | Details |

| Report Name | Medical Facility Door Closer Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Allegion, dormakaba, GEZE, OWNIC, Rutland, SARGENT, Exidor, TEKNOMEK, Kingsway Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |