What is Global InGaAs Color Sorter Market?

The Global InGaAs Color Sorter Market is a specialized segment within the broader color sorter industry, focusing on the use of Indium Gallium Arsenide (InGaAs) technology. This technology is particularly adept at sorting materials based on their color and infrared properties, making it highly effective in industries where precision and efficiency are paramount. InGaAs color sorters are widely used in the agricultural sector, especially for sorting grains, nuts, and seeds, as they can detect subtle differences in color and composition that are not visible to the human eye. This capability ensures that only the highest quality products reach the market, reducing waste and increasing profitability for producers. The market for these advanced sorting machines is expanding as more industries recognize the benefits of using InGaAs technology to enhance product quality and operational efficiency. With advancements in technology and increasing demand for high-quality agricultural products, the Global InGaAs Color Sorter Market is poised for significant growth in the coming years. The market's expansion is driven by the need for more precise sorting solutions that can handle a variety of materials with varying characteristics, ensuring that businesses can meet the stringent quality standards required in today's competitive market.

Belt-type Color Sorter, Vertical-type Color Sorter in the Global InGaAs Color Sorter Market:

In the Global InGaAs Color Sorter Market, two prominent types of color sorters are the Belt-type and Vertical-type color sorters. Belt-type color sorters are designed with a conveyor belt system that transports materials through the sorting machine. This type of sorter is particularly effective for handling larger volumes of materials, as the belt provides a continuous flow, allowing for high-speed sorting. The belt system also minimizes the risk of damage to delicate products, making it ideal for sorting fragile items like nuts and seeds. The Belt-type color sorter uses advanced InGaAs sensors to detect and sort materials based on their color and infrared properties, ensuring high accuracy and efficiency. On the other hand, Vertical-type color sorters operate by allowing materials to fall freely through a vertical chute. As the materials descend, they pass through a series of sensors that analyze their color and composition. This type of sorter is particularly effective for sorting smaller batches of materials or products that require a more gentle handling process. The Vertical-type sorter is often used in applications where space is limited, as its compact design allows it to fit into smaller processing areas. Both Belt-type and Vertical-type color sorters offer unique advantages depending on the specific needs of the operation. Belt-type sorters are preferred for their ability to handle large volumes and delicate products, while Vertical-type sorters are favored for their compact design and suitability for smaller batches. In both cases, the use of InGaAs technology enhances the sorting process by providing precise detection and separation of materials based on their color and infrared characteristics. This precision is crucial in industries where product quality and consistency are critical, such as in the food and agricultural sectors. As the demand for high-quality products continues to rise, the Global InGaAs Color Sorter Market is expected to see increased adoption of both Belt-type and Vertical-type sorters. Companies are investing in these advanced sorting solutions to improve their operational efficiency, reduce waste, and ensure that their products meet the highest quality standards. The choice between Belt-type and Vertical-type sorters ultimately depends on the specific requirements of the operation, including the volume of materials to be sorted, the space available for equipment, and the desired level of precision in the sorting process. Both types of sorters play a vital role in the Global InGaAs Color Sorter Market, offering businesses the flexibility and capability to meet the diverse needs of their customers.

Peach Kernels, Almonds, Walnuts, Pine Nuts, Others in the Global InGaAs Color Sorter Market:

The Global InGaAs Color Sorter Market finds extensive usage in the sorting of various nuts and seeds, including peach kernels, almonds, walnuts, pine nuts, and others. In the case of peach kernels, InGaAs color sorters are used to ensure that only the highest quality kernels are selected for further processing. The technology can detect subtle differences in color and composition, allowing for the removal of defective or discolored kernels that may affect the overall quality of the final product. This precision sorting process helps producers maintain a consistent quality standard, which is essential for meeting consumer expectations and regulatory requirements. Similarly, in the almond industry, InGaAs color sorters play a crucial role in ensuring that only the best almonds reach the market. The technology can identify and remove almonds with defects such as discoloration, mold, or damage, which can compromise the quality and safety of the product. By using InGaAs color sorters, almond producers can reduce waste, improve product quality, and increase profitability. Walnuts also benefit from the use of InGaAs color sorters, as the technology can effectively sort walnuts based on their color and infrared properties. This capability allows producers to remove defective or inferior walnuts, ensuring that only the highest quality nuts are packaged and sold. The use of InGaAs color sorters in the walnut industry helps maintain product consistency and quality, which is essential for building consumer trust and brand reputation. Pine nuts, known for their delicate flavor and texture, require careful handling during the sorting process. InGaAs color sorters are particularly effective in sorting pine nuts, as they can detect subtle differences in color and composition that may indicate defects or contamination. By using this advanced technology, producers can ensure that only the best pine nuts are selected for packaging and sale, enhancing product quality and consumer satisfaction. In addition to these specific nuts, InGaAs color sorters are also used in the sorting of other seeds and grains, where precision and quality are paramount. The technology's ability to detect and remove defective or inferior products ensures that only the highest quality items reach the market, reducing waste and increasing profitability for producers. As the demand for high-quality nuts and seeds continues to grow, the Global InGaAs Color Sorter Market is expected to see increased adoption of this advanced sorting technology. Producers are investing in InGaAs color sorters to improve their operational efficiency, reduce waste, and ensure that their products meet the highest quality standards. The use of InGaAs color sorters in the sorting of peach kernels, almonds, walnuts, pine nuts, and other seeds and grains is a testament to the technology's versatility and effectiveness in enhancing product quality and consistency.

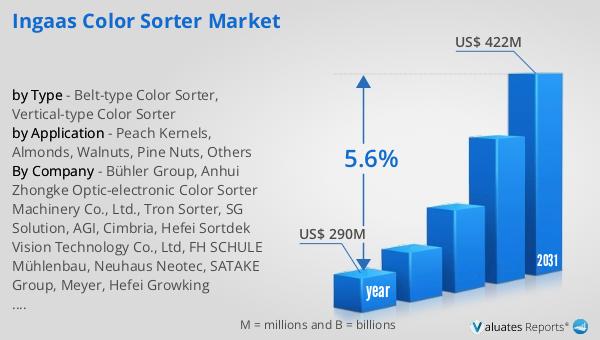

Global InGaAs Color Sorter Market Outlook:

In 2024, the global market for InGaAs Color Sorters was valued at approximately $290 million. This market is anticipated to grow significantly, reaching an estimated value of $422 million by the year 2031. This growth represents a compound annual growth rate (CAGR) of 5.6% over the forecast period. The increasing demand for high-quality agricultural products and the need for more precise sorting solutions are key factors driving this growth. As industries continue to recognize the benefits of using InGaAs technology for sorting applications, the market is expected to expand further. The ability of InGaAs color sorters to detect subtle differences in color and composition makes them an invaluable tool for ensuring product quality and consistency. This precision is particularly important in industries such as food and agriculture, where maintaining high standards is essential for meeting consumer expectations and regulatory requirements. As a result, more companies are investing in InGaAs color sorters to enhance their operational efficiency and improve product quality. The projected growth of the Global InGaAs Color Sorter Market reflects the increasing importance of advanced sorting technologies in today's competitive market. With the continued advancement of InGaAs technology and the growing demand for high-quality products, the market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | InGaAs Color Sorter Market |

| Accounted market size in year | US$ 290 million |

| Forecasted market size in 2031 | US$ 422 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Bühler Group, Anhui Zhongke Optic-electronic Color Sorter Machinery Co., Ltd., Tron Sorter, SG Solution, AGI, Cimbria, Hefei Sortdek Vision Technology Co., Ltd, FH SCHULE Mühlenbau, Neuhaus Neotec, SATAKE Group, Meyer, Hefei Growking Optoelectronic Technology Co., Ltd., Anysort Technologies Lanka (Pvt) Ltd., Anhui RealTech Manchinery company limited., Bratney |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |