What is Global Part Transfer System Market?

The Global Part Transfer System Market is a specialized segment within the industrial automation sector, focusing on the efficient movement of parts and components within manufacturing and assembly processes. These systems are designed to enhance productivity by automating the transfer of parts between different stages of production, thereby reducing manual handling and minimizing the risk of errors. The market encompasses a variety of technologies and solutions, including conveyors, robotic arms, and automated guided vehicles (AGVs), each tailored to meet specific industrial needs. As industries strive for higher efficiency and precision, the demand for advanced part transfer systems is on the rise. These systems are crucial in sectors such as automotive, electronics, and consumer goods, where high-volume production and stringent quality standards are prevalent. The market is characterized by continuous innovation, with manufacturers investing in research and development to introduce more sophisticated and adaptable systems. As a result, the Global Part Transfer System Market is poised for significant growth, driven by the increasing adoption of automation technologies across various industries. The integration of smart technologies, such as IoT and AI, further enhances the capabilities of these systems, offering real-time monitoring and predictive maintenance features.

Fully Automatic, Semi-automatic Type in the Global Part Transfer System Market:

The Global Part Transfer System Market is segmented into fully automatic and semi-automatic systems, each catering to different operational needs and levels of automation. Fully automatic part transfer systems are designed to operate with minimal human intervention, offering a seamless and efficient transfer of parts across various stages of production. These systems are equipped with advanced sensors and control mechanisms that ensure precise and accurate movement of components, thereby reducing the likelihood of errors and enhancing overall productivity. Fully automatic systems are particularly beneficial in high-volume production environments where speed and accuracy are paramount. They are commonly used in industries such as automotive and electronics, where the demand for precision and efficiency is high. The integration of technologies such as robotics and artificial intelligence further enhances the capabilities of fully automatic systems, enabling them to adapt to changing production requirements and optimize performance. On the other hand, semi-automatic part transfer systems offer a balance between automation and manual intervention. These systems are designed to assist human operators in the transfer of parts, providing a level of flexibility that fully automatic systems may not offer. Semi-automatic systems are ideal for production environments where customization and adaptability are required, allowing operators to make adjustments as needed. These systems are often used in industries where production volumes are lower, or where the complexity of tasks requires human oversight. The semi-automatic systems are equipped with user-friendly interfaces and control mechanisms that facilitate easy operation and maintenance. They offer a cost-effective solution for businesses looking to enhance their production processes without fully committing to automation. Both fully automatic and semi-automatic systems play a crucial role in the Global Part Transfer System Market, offering solutions that cater to a wide range of industrial needs. The choice between the two depends on factors such as production volume, complexity of tasks, and budget constraints. As industries continue to evolve and embrace automation, the demand for both types of systems is expected to grow. Manufacturers are continually innovating to improve the efficiency and capabilities of these systems, incorporating advanced technologies such as IoT and machine learning to enhance performance and reliability. The integration of these technologies allows for real-time monitoring and predictive maintenance, reducing downtime and improving overall operational efficiency. As a result, both fully automatic and semi-automatic part transfer systems are becoming increasingly sophisticated, offering businesses the tools they need to stay competitive in a rapidly changing market.

Industry, Business, Other in the Global Part Transfer System Market:

The Global Part Transfer System Market finds extensive usage across various sectors, including industry, business, and other areas, each benefiting from the enhanced efficiency and productivity these systems offer. In the industrial sector, part transfer systems are integral to manufacturing and assembly processes, where they facilitate the seamless movement of components between different stages of production. Industries such as automotive, electronics, and consumer goods rely heavily on these systems to maintain high production volumes and meet stringent quality standards. The automation of part transfer processes reduces the need for manual handling, minimizing the risk of errors and improving overall efficiency. This is particularly important in industries where precision and speed are critical to maintaining competitiveness. In the business sector, part transfer systems are used to streamline operations and enhance productivity. Businesses involved in logistics, warehousing, and distribution benefit from the efficient movement of goods facilitated by these systems. Automated guided vehicles (AGVs) and conveyor systems are commonly used to transport products within warehouses, reducing the reliance on manual labor and improving operational efficiency. The integration of smart technologies, such as IoT and AI, further enhances the capabilities of these systems, offering real-time tracking and monitoring of goods. This allows businesses to optimize their supply chain operations, reduce costs, and improve customer satisfaction. Beyond industry and business, part transfer systems are also used in other areas such as healthcare and agriculture. In healthcare, these systems are used to automate the movement of medical supplies and equipment within hospitals, improving efficiency and reducing the risk of contamination. In agriculture, part transfer systems are used to automate the handling and processing of crops, enhancing productivity and reducing labor costs. The versatility of part transfer systems makes them suitable for a wide range of applications, each benefiting from the enhanced efficiency and productivity they offer. Overall, the Global Part Transfer System Market plays a crucial role in enhancing efficiency and productivity across various sectors. The integration of advanced technologies and the continuous innovation in system design and functionality ensure that these systems remain relevant and effective in meeting the evolving needs of industries and businesses. As the demand for automation continues to grow, the usage of part transfer systems is expected to expand, offering new opportunities for businesses to improve their operations and stay competitive in a rapidly changing market.

Global Part Transfer System Market Outlook:

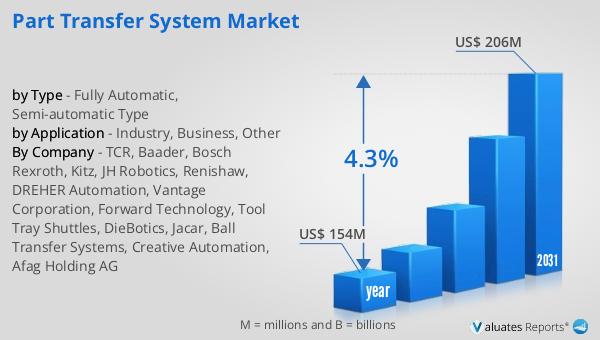

In 2024, the global market for Part Transfer Systems was valued at approximately $154 million. Looking ahead, this market is anticipated to grow, reaching an estimated size of $206 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. This steady increase in market size reflects the rising demand for automation solutions across various industries. As businesses strive to enhance efficiency and productivity, the adoption of part transfer systems is expected to rise, driving market growth. The integration of advanced technologies such as IoT and AI into these systems further enhances their capabilities, offering real-time monitoring and predictive maintenance features. This not only improves operational efficiency but also reduces downtime and maintenance costs. As a result, the Global Part Transfer System Market is poised for significant growth, offering new opportunities for businesses to improve their operations and stay competitive in a rapidly changing market. The continuous innovation in system design and functionality ensures that these systems remain relevant and effective in meeting the evolving needs of industries and businesses.

| Report Metric | Details |

| Report Name | Part Transfer System Market |

| Accounted market size in year | US$ 154 million |

| Forecasted market size in 2031 | US$ 206 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TCR, Baader, Bosch Rexroth, Kitz, JH Robotics, Renishaw, DREHER Automation, Vantage Corporation, Forward Technology, Tool Tray Shuttles, DieBotics, Jacar, Ball Transfer Systems, Creative Automation, Afag Holding AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |