What is Global Electric Resistance Welding Machine Market?

The Global Electric Resistance Welding (ERW) Machine Market is a dynamic and evolving sector that plays a crucial role in various industries worldwide. Electric Resistance Welding is a process that involves the generation of heat through electrical resistance to join metal parts. This method is widely used due to its efficiency, speed, and ability to produce strong, durable welds. The market for ERW machines encompasses a range of equipment designed to perform different types of welding, such as spot welding, seam welding, projection welding, and butt welding. These machines are essential in manufacturing processes across industries like automotive, aerospace, construction, and electronics. The demand for ERW machines is driven by the need for high-quality, reliable welding solutions that can meet the stringent standards of modern manufacturing. As industries continue to innovate and expand, the Global Electric Resistance Welding Machine Market is expected to grow, offering new opportunities for manufacturers and suppliers. The market's growth is also fueled by advancements in technology, which have led to the development of more efficient and versatile welding machines. Overall, the Global Electric Resistance Welding Machine Market is a vital component of the industrial landscape, providing the tools necessary for the production of a wide range of products.

Spot Welding, Seam Welding, Projection Welding, Butt Welding in the Global Electric Resistance Welding Machine Market:

Spot welding, seam welding, projection welding, and butt welding are integral processes within the Global Electric Resistance Welding Machine Market, each serving distinct purposes and applications. Spot welding is perhaps the most recognized form of electric resistance welding, commonly used in the automotive industry for joining sheet metal. It involves the application of pressure and electric current through electrodes to create welds at specific points. This method is favored for its speed and efficiency, making it ideal for mass production environments. Seam welding, on the other hand, is used to create continuous, leak-proof welds along a seam. This process is essential in industries where airtight or watertight seals are necessary, such as in the manufacturing of fuel tanks and pipelines. Seam welding machines are designed to handle long, continuous welds, ensuring consistency and strength throughout the joint. Projection welding is a variation that involves the use of projections or embossments on one of the workpieces to concentrate the welding current and pressure. This method is particularly useful for joining components with complex geometries or multiple layers, as it allows for precise control over the weld location and quality. Projection welding is often employed in the production of fasteners, brackets, and other small components. Butt welding, meanwhile, is used to join two pieces of metal end-to-end, creating a strong, seamless joint. This process is commonly used in the construction of pipelines, rail tracks, and other applications where long, continuous lengths of material are required. Butt welding machines are designed to handle large, heavy workpieces, providing the necessary force and precision to create high-quality welds. Each of these welding processes plays a critical role in the Global Electric Resistance Welding Machine Market, offering unique capabilities and advantages that cater to the diverse needs of modern manufacturing. As industries continue to evolve and demand more sophisticated welding solutions, the importance of these processes within the market is only expected to grow.

Automotive and Transportation, Aerospace, Oil and Gas Pipelines, Building and Construction, Electronics and Medical, Others in the Global Electric Resistance Welding Machine Market:

The Global Electric Resistance Welding Machine Market finds extensive applications across various sectors, each with its unique requirements and challenges. In the automotive and transportation industry, ERW machines are indispensable for the production of vehicle bodies, frames, and components. The ability to produce strong, reliable welds quickly and efficiently makes these machines ideal for high-volume manufacturing environments. In the aerospace sector, precision and reliability are paramount, and ERW machines are used to join critical components such as fuselage sections, wings, and engine parts. The aerospace industry demands welds that can withstand extreme conditions, and electric resistance welding provides the necessary strength and durability. In the oil and gas industry, ERW machines are used to construct pipelines and other infrastructure, where the ability to create long, continuous welds is essential. The harsh environments and high pressures encountered in this sector require welds that are both strong and leak-proof, making seam and butt welding particularly valuable. In the building and construction industry, ERW machines are used to fabricate structural components, reinforcing bars, and other elements that require robust, reliable joints. The versatility of electric resistance welding allows for the efficient production of a wide range of construction materials. In the electronics and medical sectors, precision and cleanliness are critical, and ERW machines are used to join delicate components and assemblies. The ability to produce high-quality welds without introducing contaminants is essential in these industries, where even minor defects can have significant consequences. Finally, the Global Electric Resistance Welding Machine Market also serves a variety of other industries, including consumer goods, appliances, and heavy machinery. The adaptability and efficiency of electric resistance welding make it a valuable tool for manufacturers across the spectrum, enabling the production of high-quality products that meet the demands of modern consumers.

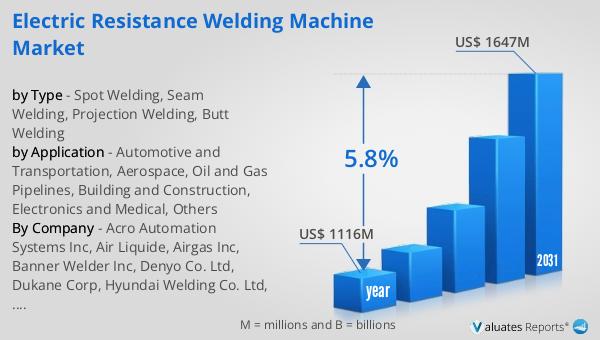

Global Electric Resistance Welding Machine Market Outlook:

The global market for Electric Resistance Welding Machines was valued at approximately $1,116 million in 2024, and it is anticipated to expand to a revised size of around $1,647 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.8% over the forecast period. This upward trend in the market is indicative of the increasing demand for efficient and reliable welding solutions across various industries. The growth is driven by the need for advanced manufacturing techniques that can meet the stringent quality standards required in sectors such as automotive, aerospace, and construction. As industries continue to innovate and expand, the demand for electric resistance welding machines is expected to rise, offering new opportunities for manufacturers and suppliers. The market's expansion is also supported by technological advancements that have led to the development of more efficient and versatile welding machines. These innovations have enabled manufacturers to produce high-quality welds with greater precision and speed, meeting the evolving needs of modern manufacturing. Overall, the Global Electric Resistance Welding Machine Market is poised for significant growth, driven by the increasing demand for high-quality, reliable welding solutions across a wide range of industries.

| Report Metric | Details |

| Report Name | Electric Resistance Welding Machine Market |

| Accounted market size in year | US$ 1116 million |

| Forecasted market size in 2031 | US$ 1647 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Acro Automation Systems Inc, Air Liquide, Airgas Inc, Banner Welder Inc, Denyo Co. Ltd, Dukane Corp, Hyundai Welding Co. Ltd, Schlatter Holding Ag, Yaskawa America Inc, ATLANTIC CHINA WELDING CONSUMABLES |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |