What is Stationary Shaft Magnetic Pump - Global Market?

The stationary shaft magnetic pump is a specialized type of pump that operates without the need for traditional seals, which are often prone to wear and leakage. This pump uses magnetic coupling to transfer torque from the motor to the impeller, ensuring a leak-free operation. The global market for stationary shaft magnetic pumps is driven by the increasing demand for efficient and reliable pumping solutions across various industries. These pumps are particularly valued for their ability to handle hazardous and corrosive fluids without the risk of leakage, making them ideal for applications in the chemical, oil and gas, and pharmaceutical industries. The market is characterized by technological advancements that enhance the performance and durability of these pumps, as well as by the growing emphasis on environmental safety and regulatory compliance. As industries continue to seek sustainable and cost-effective solutions, the demand for stationary shaft magnetic pumps is expected to grow, supported by their operational efficiency and low maintenance requirements. The market is also influenced by the expansion of industrial activities in emerging economies, where the need for robust and efficient pumping systems is on the rise.

Single-stage, Multistage in the Stationary Shaft Magnetic Pump - Global Market:

Single-stage and multistage stationary shaft magnetic pumps are two primary configurations that cater to different industrial needs. Single-stage pumps are designed for applications requiring moderate pressure and flow rates. They are typically used in scenarios where the fluid needs to be moved over short distances or where the pressure requirements are not exceedingly high. These pumps are favored for their simplicity, ease of maintenance, and cost-effectiveness. They are commonly employed in general industrial applications, water treatment facilities, and in processes where the fluid characteristics do not demand complex pumping solutions. On the other hand, multistage stationary shaft magnetic pumps are engineered for high-pressure applications. They consist of multiple impellers mounted on a single shaft, allowing them to generate higher pressures by passing the fluid through several stages. This makes them suitable for applications such as boiler feedwater systems, high-pressure cleaning, and in industries where fluids need to be transported over long distances or elevated to significant heights. The choice between single-stage and multistage pumps depends largely on the specific requirements of the application, including the nature of the fluid, the required pressure, and the operational environment. In the global market, both single-stage and multistage pumps are witnessing increasing demand due to their ability to handle a wide range of fluids, including those that are corrosive, toxic, or require precise handling. The versatility of these pumps makes them indispensable in sectors such as oil and gas, where they are used for transferring crude oil, natural gas, and other hydrocarbons. In the chemical industry, they are employed for handling aggressive chemicals and solvents, ensuring safe and efficient operations. The food and pharmaceutical industries also benefit from these pumps, as they provide a hygienic and contamination-free solution for transferring sensitive products. The global market for single-stage and multistage stationary shaft magnetic pumps is characterized by continuous innovation, with manufacturers focusing on improving the efficiency, reliability, and environmental compatibility of their products. This includes the development of pumps with enhanced corrosion resistance, energy efficiency, and the ability to operate under extreme conditions. As industries continue to evolve and demand more sophisticated pumping solutions, the market for these pumps is expected to expand, driven by the need for high-performance, durable, and environmentally friendly pumping systems.

Chemical, General Industry, Oil & Gas, Food & Pharmaceutical, Others in the Stationary Shaft Magnetic Pump - Global Market:

Stationary shaft magnetic pumps are extensively used across various industries due to their unique ability to provide leak-free and reliable fluid handling solutions. In the chemical industry, these pumps are crucial for handling corrosive and hazardous chemicals safely. Their design eliminates the risk of leakage, which is essential when dealing with substances that can pose environmental or safety hazards. This makes them ideal for applications such as chemical processing, where maintaining the integrity of the fluid is paramount. In the general industry, stationary shaft magnetic pumps are used for a wide range of applications, including water treatment, cooling systems, and the transfer of various industrial fluids. Their robust construction and ability to handle different types of fluids make them a versatile choice for many industrial processes. In the oil and gas sector, these pumps are employed for the transportation of crude oil, natural gas, and other hydrocarbons. Their ability to operate under high pressure and handle volatile substances without leakage is particularly valuable in this industry, where safety and efficiency are top priorities. The food and pharmaceutical industries also rely on stationary shaft magnetic pumps for their operations. In these sectors, maintaining product purity and preventing contamination are critical. The design of these pumps ensures that there is no contact between the fluid and the external environment, making them suitable for handling sensitive products such as pharmaceuticals, food ingredients, and beverages. Additionally, these pumps are used in other industries, including power generation, mining, and wastewater treatment, where their durability and efficiency are highly valued. The global market for stationary shaft magnetic pumps is driven by the increasing demand for reliable and efficient fluid handling solutions across these diverse sectors. As industries continue to prioritize safety, environmental compliance, and operational efficiency, the adoption of these pumps is expected to grow, supported by their proven performance and versatility.

Stationary Shaft Magnetic Pump - Global Market Outlook:

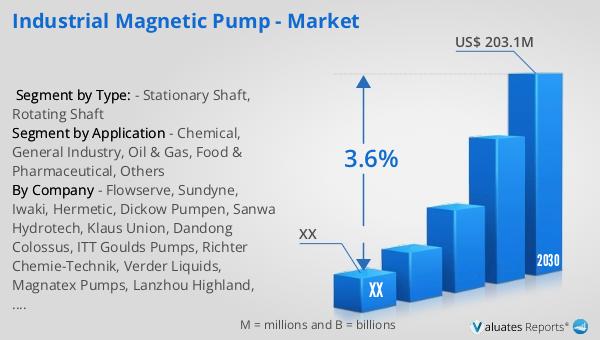

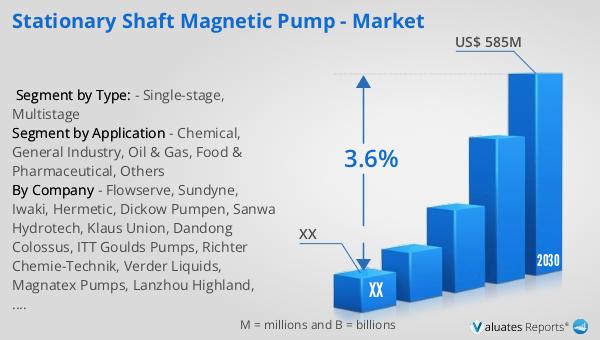

The global market for stationary shaft magnetic pumps was valued at approximately US$ 458.3 million in 2023. This market is projected to grow, reaching an estimated size of US$ 585 million by 2030, with a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and reliable pumping solutions across various industries. In North America, the market for stationary shaft magnetic pumps was valued at a significant amount in 2023, and it is expected to continue its growth trajectory through 2030. The specific figures for the North American market highlight the region's strong industrial base and the growing need for advanced pumping technologies. The steady growth rate reflects the ongoing investments in infrastructure and industrial activities, as well as the emphasis on adopting environmentally friendly and efficient technologies. The market dynamics are influenced by factors such as technological advancements, regulatory requirements, and the expansion of industrial activities in emerging economies. As industries continue to seek sustainable and cost-effective solutions, the demand for stationary shaft magnetic pumps is expected to rise, supported by their operational efficiency and low maintenance requirements.

| Report Metric | Details |

| Report Name | Stationary Shaft Magnetic Pump - Market |

| Forecasted market size in 2030 | US$ 585 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Flowserve, Sundyne, Iwaki, Hermetic, Dickow Pumpen, Sanwa Hydrotech, Klaus Union, Dandong Colossus, ITT Goulds Pumps, Richter Chemie-Technik, Verder Liquids, Magnatex Pumps, Lanzhou Highland, ASSOMA, Taicang Magnetic Pump, March Manufacturing, GemmeCotti, Desmi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |