What is SMT AOI Inspection Equipment - Global Market?

SMT AOI (Surface Mount Technology Automated Optical Inspection) equipment is a crucial component in the electronics manufacturing industry, designed to inspect printed circuit boards (PCBs) for defects during the assembly process. This equipment uses advanced imaging technology to automatically scan and analyze PCBs, identifying issues such as missing components, soldering defects, and misalignments. The global market for SMT AOI inspection equipment is driven by the increasing demand for high-quality electronic products and the need for efficient production processes. As electronics become more complex and miniaturized, the precision and speed offered by SMT AOI systems are indispensable. These systems not only enhance the quality control process but also reduce the need for manual inspection, thereby saving time and labor costs. The market is characterized by continuous technological advancements, with manufacturers focusing on improving the accuracy, speed, and user-friendliness of these systems. As industries such as consumer electronics, telecommunications, and automotive continue to grow, the demand for SMT AOI inspection equipment is expected to rise, making it a vital part of the global electronics manufacturing landscape.

Inline, Offline in the SMT AOI Inspection Equipment - Global Market:

Inline and offline SMT AOI inspection equipment are two primary configurations used in the electronics manufacturing industry, each serving distinct purposes and offering unique advantages. Inline SMT AOI systems are integrated directly into the production line, allowing for real-time inspection of PCBs as they move through the assembly process. This setup is ideal for high-volume production environments where speed and efficiency are paramount. Inline systems provide immediate feedback, enabling manufacturers to quickly identify and rectify defects, thus minimizing downtime and reducing the risk of defective products reaching the market. These systems are often equipped with high-speed cameras and advanced algorithms to ensure rapid and accurate inspection, making them suitable for industries with stringent quality requirements, such as automotive and telecommunications. On the other hand, offline SMT AOI systems are standalone units that are not directly connected to the production line. These systems are typically used for batch processing or in environments where production volumes are lower. Offline AOI equipment allows for more detailed and thorough inspections, as operators can manually load and inspect PCBs at their own pace. This flexibility makes offline systems ideal for prototyping, small-scale production, or when dealing with complex or custom PCBs that require more attention. Additionally, offline systems can be used for rework and repair processes, providing manufacturers with the ability to inspect and correct defects on previously assembled boards. Both inline and offline SMT AOI systems play a crucial role in ensuring the quality and reliability of electronic products. While inline systems offer speed and efficiency for high-volume production, offline systems provide flexibility and detailed inspection capabilities for specialized applications. The choice between inline and offline systems depends on various factors, including production volume, complexity of the PCBs, and specific quality requirements. As the electronics manufacturing industry continues to evolve, the demand for both types of SMT AOI systems is expected to grow, driven by the need for improved quality control and the increasing complexity of electronic devices.

Consumer Electronics, Telecommunications Equipment, Automotive, Others in the SMT AOI Inspection Equipment - Global Market:

SMT AOI inspection equipment is widely used across various industries, including consumer electronics, telecommunications equipment, automotive, and others, each benefiting from the enhanced quality control and efficiency these systems provide. In the consumer electronics sector, the demand for compact, high-performance devices such as smartphones, tablets, and wearables has led to the adoption of SMT AOI systems to ensure the precision and reliability of PCBs. These systems help manufacturers maintain high standards of quality while keeping up with the fast-paced production schedules typical of consumer electronics. By identifying defects early in the production process, SMT AOI equipment minimizes the risk of faulty products reaching consumers, thereby protecting brand reputation and reducing warranty costs. In the telecommunications equipment industry, the complexity and critical nature of devices such as routers, switches, and base stations necessitate rigorous quality control measures. SMT AOI inspection equipment plays a vital role in this sector by providing accurate and efficient inspection of PCBs, ensuring that components are correctly placed and soldered. This is crucial for maintaining the performance and reliability of telecommunications infrastructure, which is essential for seamless communication and data transfer. The use of SMT AOI systems in this industry helps manufacturers meet stringent quality standards and regulatory requirements, while also improving production efficiency. The automotive industry also relies heavily on SMT AOI inspection equipment to ensure the safety and reliability of electronic components used in vehicles. With the increasing integration of advanced electronics in modern cars, such as infotainment systems, advanced driver-assistance systems (ADAS), and electric vehicle components, the need for precise and reliable PCB inspection has become more critical than ever. SMT AOI systems help automotive manufacturers detect and correct defects early in the production process, reducing the risk of costly recalls and enhancing vehicle safety. The ability to maintain high-quality standards is crucial in this industry, where even minor defects can have significant consequences. Beyond these primary industries, SMT AOI inspection equipment is also used in various other sectors, including aerospace, medical devices, and industrial electronics. In aerospace, the reliability and performance of electronic components are paramount, making SMT AOI systems an essential part of the manufacturing process. Similarly, in the medical device industry, where precision and reliability are critical, these systems help ensure that electronic components meet the necessary quality standards. In industrial electronics, SMT AOI equipment aids in the production of robust and reliable components used in various applications, from automation systems to power electronics. Overall, the versatility and effectiveness of SMT AOI inspection equipment make it an invaluable tool across a wide range of industries, contributing to improved product quality and manufacturing efficiency.

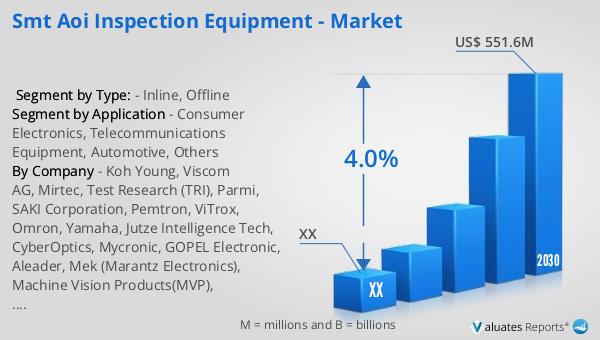

SMT AOI Inspection Equipment - Global Market Outlook:

The global market for SMT AOI inspection equipment was valued at approximately $420.8 million in 2023 and is projected to grow to around $551.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.0% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for high-quality electronic products and the need for efficient production processes across various industries. In North America, the market for SMT AOI inspection equipment was valued at a significant amount in 2023, with expectations of continued growth through 2030. The region's market dynamics are influenced by the presence of major electronics manufacturers and the adoption of advanced manufacturing technologies. The projected growth in the North American market underscores the importance of SMT AOI systems in maintaining competitive advantage and meeting the evolving quality standards in the electronics industry. As manufacturers continue to seek ways to enhance production efficiency and product quality, the demand for SMT AOI inspection equipment is expected to rise, driving market growth globally and regionally.

| Report Metric | Details |

| Report Name | SMT AOI Inspection Equipment - Market |

| Forecasted market size in 2030 | US$ 551.6 million |

| CAGR | 4.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Koh Young, Viscom AG, Mirtec, Test Research (TRI), Parmi, SAKI Corporation, Pemtron, ViTrox, Omron, Yamaha, Jutze Intelligence Tech, CyberOptics, Mycronic, GOPEL Electronic, Aleader, Mek (Marantz Electronics), Machine Vision Products(MVP), ZhenHuaXing Technology, Shenzhen JT Automation Equipment, Shanghai Holly |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |