What is Global Surface Pumps Market?

The Global Surface Pumps Market refers to the worldwide industry focused on the production, distribution, and utilization of surface pumps. Surface pumps are mechanical devices designed to move fluids, such as water, oil, and chemicals, from one place to another. These pumps are typically installed above ground and are used in various applications, including agriculture, industrial processes, and municipal water systems. The market encompasses a wide range of pump types, including centrifugal pumps, positive displacement pumps, and others, each suited for specific tasks and industries. The demand for surface pumps is driven by factors such as the need for efficient water management, the growth of industrial activities, and the expansion of infrastructure projects. As industries continue to evolve and environmental concerns become more prominent, the Global Surface Pumps Market is expected to see significant advancements and innovations to meet the changing needs of its diverse customer base.

Centrifugal Pumps, Positive Displacement Pumps, Other in the Global Surface Pumps Market:

Centrifugal pumps, positive displacement pumps, and other types of pumps play crucial roles in the Global Surface Pumps Market. Centrifugal pumps are among the most commonly used types of surface pumps. They operate by converting rotational kinetic energy, typically from an electric motor or engine, into hydrodynamic energy to move fluids. These pumps are highly efficient for transferring large volumes of liquids over short to medium distances and are widely used in water supply systems, irrigation, and industrial processes. Their simple design, ease of maintenance, and ability to handle a variety of fluids make them a popular choice in many sectors. Positive displacement pumps, on the other hand, work by trapping a fixed amount of fluid and then forcing (displacing) that trapped volume into the discharge pipe. This category includes gear pumps, diaphragm pumps, and piston pumps, each with unique mechanisms suited for specific applications. Positive displacement pumps are particularly effective in situations where precise flow control is required, such as in chemical processing, oil and gas production, and food and beverage manufacturing. They are capable of handling high-viscosity fluids and maintaining a consistent flow rate regardless of pressure changes, making them indispensable in many industrial settings. Other types of surface pumps include peristaltic pumps, which use a rotating mechanism to compress and move fluid through a flexible tube, and jet pumps, which utilize the Venturi effect to draw fluid into the pump. These specialized pumps are used in niche applications where their unique operating principles offer advantages over more conventional pump types. For instance, peristaltic pumps are often used in medical and laboratory settings due to their ability to handle delicate fluids without contamination, while jet pumps are commonly employed in residential water systems and shallow well applications. The diversity of pump types within the Global Surface Pumps Market ensures that there is a suitable solution for virtually any fluid transfer need, from simple water distribution to complex industrial processes. As technology continues to advance, the development of more efficient, durable, and versatile pumps will likely drive further growth and innovation in this dynamic market.

Chemical, Oil & Gas, Mining, Other in the Global Surface Pumps Market:

The Global Surface Pumps Market finds extensive usage across various industries, including chemical, oil and gas, mining, and others. In the chemical industry, surface pumps are essential for handling a wide range of fluids, including corrosive and hazardous chemicals. These pumps are used in processes such as chemical mixing, transfer, and dosing, where precise control and reliability are critical. Centrifugal pumps are often preferred for their ability to handle large volumes of fluid, while positive displacement pumps are chosen for applications requiring accurate flow control and the ability to handle high-viscosity fluids. In the oil and gas industry, surface pumps play a vital role in the extraction, processing, and transportation of oil and gas. They are used in various stages of production, from pumping crude oil from wells to transporting refined products through pipelines. Positive displacement pumps are particularly valuable in this sector due to their ability to handle high-pressure and high-viscosity fluids, making them ideal for tasks such as injecting chemicals into wells and transferring heavy crude oil. The mining industry also relies heavily on surface pumps for dewatering operations, slurry transport, and mineral processing. Centrifugal pumps are commonly used for their efficiency in moving large volumes of water and slurry, while positive displacement pumps are employed for handling abrasive and viscous materials. In addition to these primary industries, surface pumps are used in a variety of other applications, including agriculture, municipal water systems, and construction. In agriculture, surface pumps are essential for irrigation and water management, ensuring that crops receive the necessary water supply. Municipal water systems use surface pumps for water distribution and wastewater treatment, providing clean water to communities and managing sewage and stormwater. In construction, surface pumps are used for dewatering sites, supplying water for concrete mixing, and other essential tasks. The versatility and reliability of surface pumps make them indispensable across these diverse industries, driving demand and innovation in the Global Surface Pumps Market.

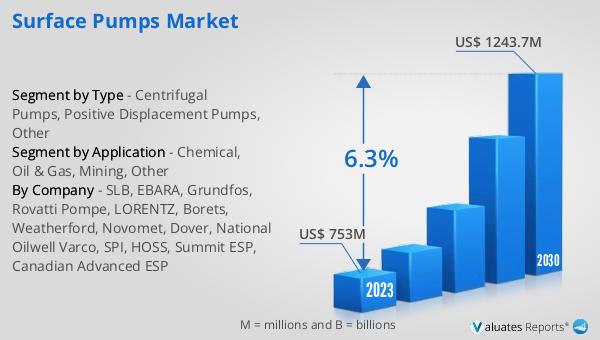

Global Surface Pumps Market Outlook:

The global Surface Pumps market, valued at US$ 753 million in 2023, is projected to grow significantly, reaching an estimated US$ 1243.7 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 6.3% over the forecast period from 2024 to 2030. The market's expansion is driven by increasing demand across various industries, including agriculture, oil and gas, chemical processing, and municipal water systems. As these industries continue to grow and evolve, the need for efficient and reliable surface pumps becomes more critical. Technological advancements and innovations in pump design and materials are also contributing to the market's growth, offering improved performance, durability, and energy efficiency. Additionally, environmental concerns and regulatory requirements are pushing industries to adopt more sustainable and efficient pumping solutions, further boosting the demand for advanced surface pumps. The market's robust growth outlook underscores the importance of surface pumps in modern industrial and infrastructure applications, highlighting their role in ensuring efficient fluid management and supporting the development of critical sectors worldwide.

| Report Metric | Details |

| Report Name | Surface Pumps Market |

| Accounted market size in 2023 | US$ 753 million |

| Forecasted market size in 2030 | US$ 1243.7 million |

| CAGR | 6.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SLB, EBARA, Grundfos, Rovatti Pompe, LORENTZ, Borets, Weatherford, Novomet, Dover, National Oilwell Varco, SPI, HOSS, Summit ESP, Canadian Advanced ESP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |