What is Global Sulfur Recovery Technology Market?

The Global Sulfur Recovery Technology Market is a specialized sector focused on the extraction and recovery of sulfur from various industrial processes. This market is crucial because sulfur is a valuable byproduct used in numerous applications, including the production of sulfuric acid, fertilizers, and in the petroleum refining process. The technology primarily involves the conversion of hydrogen sulfide (H2S), a toxic gas found in natural gas and petroleum, into elemental sulfur. This conversion is essential not only for environmental reasons, as it reduces harmful emissions, but also for economic purposes, as it allows industries to recover and utilize sulfur efficiently. The market is driven by stringent environmental regulations and the increasing demand for sulfur in various industries. As industries continue to expand and environmental concerns grow, the demand for advanced sulfur recovery technologies is expected to rise, making this market a vital component of the global industrial landscape.

in the Global Sulfur Recovery Technology Market:

The Global Sulfur Recovery Technology Market encompasses a variety of technologies and methods used by different customers to meet their specific needs. One of the most widely used methods is the Claus Process, which is the industry standard for sulfur recovery. This process involves the partial combustion of hydrogen sulfide to produce sulfur dioxide, which then reacts with more hydrogen sulfide to produce water and elemental sulfur. The Claus Process is favored for its efficiency and cost-effectiveness, making it a popular choice among refineries and gas processing plants. Another method is the Tail Gas Treatment process, which is often used in conjunction with the Claus Process to enhance sulfur recovery rates. This process involves treating the residual gases from the Claus Process to extract additional sulfur, thereby increasing the overall recovery efficiency. Additionally, the SuperClaus process is an advanced version of the Claus Process that offers higher recovery rates and lower emissions. It is particularly useful in situations where environmental regulations are stringent, and higher recovery rates are required. The Selectox process is another technology used in the sulfur recovery market. It involves the selective oxidation of hydrogen sulfide to sulfur dioxide, which then reacts with more hydrogen sulfide to produce sulfur. This process is known for its high efficiency and low operating costs, making it an attractive option for many industries. Furthermore, the Cold Bed Adsorption process is used in situations where low-temperature operations are necessary. This process involves the adsorption of hydrogen sulfide onto a solid adsorbent, which is then regenerated to release the sulfur. This method is particularly useful in applications where energy efficiency is a priority. Each of these technologies has its own advantages and disadvantages, and the choice of technology often depends on the specific requirements of the customer, such as the desired recovery rate, environmental regulations, and cost considerations. As the demand for sulfur recovery continues to grow, it is likely that new technologies and methods will be developed to meet the evolving needs of the market.

Petrochemical, Natural Gas, Coal Chemical, Others in the Global Sulfur Recovery Technology Market:

The usage of Global Sulfur Recovery Technology Market spans across various industries, including petrochemical, natural gas, coal chemical, and others. In the petrochemical industry, sulfur recovery is a critical process due to the high levels of hydrogen sulfide present in crude oil. Refineries use sulfur recovery technologies to convert this hydrogen sulfide into elemental sulfur, which can then be used in the production of sulfuric acid, fertilizers, and other chemicals. This not only helps in reducing emissions but also provides a valuable byproduct that can be sold or used internally. In the natural gas industry, sulfur recovery is equally important as natural gas often contains significant amounts of hydrogen sulfide. Gas processing plants use sulfur recovery technologies to remove hydrogen sulfide from the gas stream, ensuring that the gas meets quality standards and environmental regulations. The recovered sulfur can then be used in various applications, providing an additional revenue stream for gas producers. In the coal chemical industry, sulfur recovery is used to treat the gases produced during coal gasification and other processes. These gases often contain hydrogen sulfide, which needs to be removed to prevent environmental pollution and to recover valuable sulfur. The recovered sulfur can be used in the production of chemicals and fertilizers, contributing to the overall efficiency and sustainability of the coal chemical industry. Other industries that use sulfur recovery technologies include wastewater treatment, where hydrogen sulfide is often present in the waste gases, and the pulp and paper industry, where sulfur compounds are used in the pulping process. In these industries, sulfur recovery technologies help in reducing emissions and recovering valuable sulfur, contributing to environmental sustainability and economic efficiency. As environmental regulations become more stringent and the demand for sulfur continues to grow, the usage of sulfur recovery technologies is expected to increase across these industries.

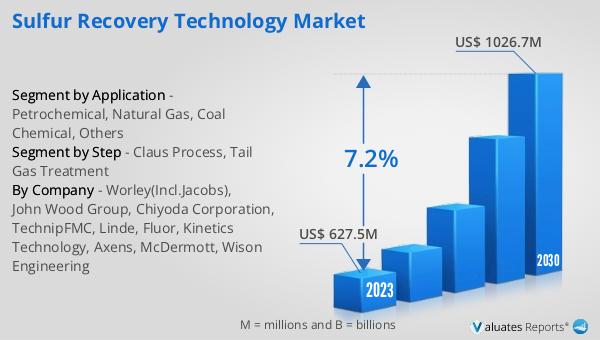

Global Sulfur Recovery Technology Market Outlook:

The global market for Sulfur Recovery Technology was valued at approximately $2,094 million in 2024, with expectations to expand to around $2,767 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. A significant portion of this market is dominated by the Claus Process, a primary category within sulfur recovery technologies. In 2024, the Claus Process was valued at about $1,290.01 million and is anticipated to reach approximately $1,627.24 million by 2031, indicating a CAGR of 3.26% from 2025 to 2031. This growth is driven by the increasing demand for efficient sulfur recovery solutions across various industries, including petrochemical, natural gas, and coal chemical sectors. The Claus Process remains a preferred choice due to its cost-effectiveness and high recovery rates, making it a cornerstone technology in the sulfur recovery market. As industries continue to seek ways to reduce emissions and recover valuable byproducts, the demand for advanced sulfur recovery technologies like the Claus Process is expected to remain strong, contributing to the overall growth of the market.

| Report Metric | Details |

| Report Name | Sulfur Recovery Technology Market |

| Accounted market size in year | US$ 2094 million |

| Forecasted market size in 2031 | US$ 2767 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Step |

|

| Segment by Application |

|

| By Region |

|

| By Company | Worley (Incl.Jacobs), John Wood Group, Technip Energies, Fluor, Chiyoda Corporation, Linde, Shell, MAIRE, Axens, Sunway Chemical, Honeywell, Topsoe |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |