What is Global Diaphragm Valves for Pharmaceutical Process Market?

The Global Diaphragm Valves for Pharmaceutical Process Market is a specialized segment within the broader industrial valves market, focusing on the unique needs of the pharmaceutical industry. Diaphragm valves are essential components in pharmaceutical manufacturing due to their ability to handle various fluids, including corrosive and viscous substances, without contamination. These valves are designed to meet stringent hygiene standards, ensuring that the pharmaceutical products remain uncontaminated throughout the production process. The market for these valves is driven by the increasing demand for pharmaceutical products, advancements in biopharmaceuticals, and the need for efficient and reliable fluid control systems. As the pharmaceutical industry continues to expand globally, the demand for high-quality diaphragm valves is expected to grow, driven by the need for compliance with regulatory standards and the push for more efficient production processes. The market is characterized by a range of products tailored to different applications, including water systems, cleaning processes, and filtration systems, each requiring specific valve characteristics to ensure optimal performance. The global market is competitive, with several key players offering innovative solutions to meet the evolving needs of the pharmaceutical sector.

Stainless Steel, Plastic, Others in the Global Diaphragm Valves for Pharmaceutical Process Market:

In the Global Diaphragm Valves for Pharmaceutical Process Market, materials play a crucial role in determining the performance and suitability of the valves for specific applications. Stainless steel is the most prominent material used in these valves, accounting for over 60% of the market share. This is due to its excellent corrosion resistance, durability, and ability to withstand high temperatures and pressures, making it ideal for the rigorous demands of pharmaceutical processes. Stainless steel diaphragm valves are particularly favored in applications where hygiene and cleanliness are paramount, as they can be easily sterilized and do not react with the chemicals used in pharmaceutical production. On the other hand, plastic diaphragm valves offer a cost-effective alternative, especially in applications where the operating conditions are less demanding. Plastics such as PVC, PP, and PVDF are commonly used, providing good chemical resistance and lightweight properties. These valves are often used in less critical applications or where metal contamination must be avoided. However, they may not offer the same level of durability and temperature resistance as their stainless steel counterparts. Other materials, such as elastomers and composites, are also used in diaphragm valves, offering specific advantages like flexibility and resistance to certain chemicals. These materials are often used in the diaphragm itself, which is a critical component of the valve, responsible for controlling the flow of fluids. The choice of material for diaphragm valves in the pharmaceutical process market is influenced by several factors, including the nature of the fluid being handled, the operating environment, and the specific requirements of the application. Manufacturers are continually innovating to develop materials that offer improved performance, longer service life, and compliance with stringent regulatory standards. This focus on material innovation is crucial as the pharmaceutical industry demands valves that can handle increasingly complex and diverse processes. The selection of the appropriate material is vital to ensure the reliability and efficiency of diaphragm valves in pharmaceutical applications, as it directly impacts the valve's ability to maintain a sterile and uncontaminated environment. As the market evolves, the demand for advanced materials that can meet the growing challenges of pharmaceutical manufacturing is expected to drive further developments in diaphragm valve technology.

Pharmaceutical Water System, CIP and SIP System, Filtration and Filling, Others in the Global Diaphragm Valves for Pharmaceutical Process Market:

The usage of Global Diaphragm Valves for Pharmaceutical Process Market is extensive and varied, catering to several critical areas within the pharmaceutical industry. One of the primary applications is in Pharmaceutical Water Systems, where diaphragm valves play a crucial role in ensuring the purity and quality of water used in drug manufacturing. These valves help maintain a sterile environment by preventing contamination and allowing precise control over water flow, which is essential for producing high-quality pharmaceutical products. In Clean-In-Place (CIP) and Steam-In-Place (SIP) systems, diaphragm valves are indispensable due to their ability to withstand high temperatures and aggressive cleaning agents. These systems are vital for maintaining hygiene and preventing cross-contamination in pharmaceutical production facilities. Diaphragm valves ensure that cleaning processes are efficient and effective, allowing for quick and thorough sterilization of equipment without the need for disassembly. In Filtration and Filling processes, diaphragm valves provide precise control over fluid flow, ensuring that the correct volumes are filtered and filled into containers. This precision is crucial for maintaining product consistency and quality, as even minor deviations can impact the efficacy and safety of pharmaceutical products. Diaphragm valves are designed to handle a wide range of viscosities and pressures, making them suitable for various filtration and filling applications. Other areas where diaphragm valves are used include bioprocessing, where they help manage the flow of biological materials, and in the handling of aggressive chemicals used in drug synthesis. The versatility and reliability of diaphragm valves make them an essential component in the pharmaceutical industry, where maintaining product integrity and safety is of utmost importance. As the pharmaceutical industry continues to evolve, the demand for high-performance diaphragm valves is expected to grow, driven by the need for more efficient and reliable fluid control solutions.

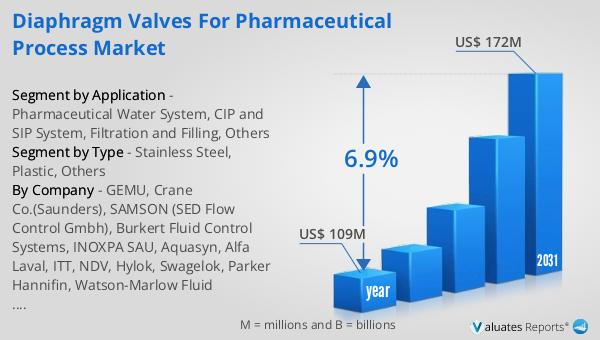

Global Diaphragm Valves for Pharmaceutical Process Market Outlook:

The global market for Diaphragm Valves for Pharmaceutical Process was valued at $139 million in 2024 and is anticipated to reach a revised size of $212 million by 2031, growing at a compound annual growth rate (CAGR) of 6.5% during the forecast period. GEMU is a significant global player in this market, holding about 20% of the market share. Other key players include Crane Co., Saunders, SAMSON, SED Flow Control GmbH, and Burkert Fluid Control Systems. In terms of materials, stainless steel is the largest segment, accounting for over 60% of the market share. Regarding application, the pharmaceutical water system segment holds a share of over 30%. The expansion of the global pharmaceutical industry and the increase in biopharmaceutical production capacity are significant drivers of this market. The global biopharmaceutical market size is expected to reach $560 billion by 2028, indicating a robust growth trajectory for diaphragm valves in pharmaceutical processes. This growth is fueled by the increasing demand for high-quality pharmaceutical products and the need for efficient and reliable fluid control systems that comply with stringent regulatory standards. As the market continues to evolve, the focus on innovation and material advancements will be crucial in meeting the growing demands of the pharmaceutical industry.

| Report Metric | Details |

| Report Name | Diaphragm Valves for Pharmaceutical Process Market |

| Accounted market size in year | US$ 139 million |

| Forecasted market size in 2031 | US$ 212 million |

| CAGR | 6.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | GEMU, Crane Co.(Saunders), SAMSON (SED Flow Control Gmbh), Burkert Fluid Control Systems, INOXPA SAU, Aquasyn, Alfa Laval, ITT, NDV, Hylok, Swagelok, Parker Hannifin, Watson-Marlow Fluid Technology Group (ASEPCO), Steel & O'Brien, Shanghai REMY, Rodaff Fluid Tech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |