What is Global Direct Thermal Printing Film Market?

The Global Direct Thermal Printing Film Market is a specialized segment within the broader printing industry, focusing on films used in direct thermal printing processes. These films are essential for creating images or text on paper without the need for ink, toner, or ribbons. Instead, they rely on heat-sensitive materials that change color when exposed to a thermal print head. This technology is widely used in various applications due to its simplicity, cost-effectiveness, and efficiency. The market for direct thermal printing films is driven by the increasing demand for quick and reliable printing solutions across different sectors, including retail, logistics, and healthcare. As businesses seek to streamline operations and reduce costs, the adoption of direct thermal printing films is expected to grow. The market is characterized by a diverse range of products, catering to different needs and specifications, from high durability to specific environmental conditions. With advancements in technology and the growing emphasis on sustainability, the Global Direct Thermal Printing Film Market is poised for significant growth, offering innovative solutions to meet the evolving demands of modern industries.

White Thermal Printing Film, Transparent Thermal Printing Film in the Global Direct Thermal Printing Film Market:

White Thermal Printing Film and Transparent Thermal Printing Film are two prominent types of films within the Global Direct Thermal Printing Film Market, each serving distinct purposes and applications. White Thermal Printing Film is primarily used for applications where high contrast and readability are essential. This type of film is coated with a white layer that enhances the visibility of printed information, making it ideal for labels, tags, and tickets that require clear and legible text or images. The white background provides a stark contrast to the printed material, ensuring that information is easily discernible even in low-light conditions. This makes it particularly useful in industries such as logistics and retail, where quick and accurate information retrieval is crucial. On the other hand, Transparent Thermal Printing Film is designed for applications where the underlying surface or product needs to remain visible. This type of film is often used in situations where aesthetics are important, such as in packaging or labeling of high-end products. The transparency of the film allows for the product or surface beneath to be seen, while still providing the necessary information or branding. This is particularly beneficial in the cosmetics and personal care industry, where the appearance of the product is a key selling point. Transparent films are also used in applications where the label needs to be discreet or where the information is secondary to the product itself. Both types of films are engineered to withstand various environmental conditions, ensuring durability and longevity of the printed information. They are designed to resist smudging, fading, and other forms of degradation that can occur over time or with exposure to different elements. This makes them suitable for a wide range of applications, from short-term use in retail environments to long-term use in industrial settings. The choice between white and transparent thermal printing films often depends on the specific requirements of the application, including factors such as visibility, aesthetics, and environmental conditions. As the Global Direct Thermal Printing Film Market continues to evolve, manufacturers are investing in research and development to enhance the performance and versatility of these films. Innovations in coating technologies, for instance, are leading to films that offer improved print quality, greater resistance to environmental factors, and enhanced compatibility with different printing systems. Additionally, there is a growing emphasis on sustainability, with manufacturers exploring eco-friendly materials and production processes to reduce the environmental impact of thermal printing films. This is in response to increasing consumer and regulatory pressure for more sustainable packaging and labeling solutions. As a result, the market is witnessing the introduction of films that are not only high-performing but also environmentally responsible. In conclusion, White Thermal Printing Film and Transparent Thermal Printing Film play crucial roles in the Global Direct Thermal Printing Film Market, each offering unique benefits and applications. Their continued development and innovation are essential to meeting the diverse needs of industries worldwide, ensuring that businesses can effectively communicate information while maintaining the integrity and appeal of their products.

Cosmetics and Personal Care, Pharmaceutical, Food and Beverage, Luggage Tags, Others in the Global Direct Thermal Printing Film Market:

The Global Direct Thermal Printing Film Market finds extensive usage across various sectors, including Cosmetics and Personal Care, Pharmaceutical, Food and Beverage, Luggage Tags, and others. In the Cosmetics and Personal Care industry, direct thermal printing films are used for labeling and packaging purposes. The ability to produce high-quality, durable labels that can withstand exposure to moisture, oils, and other substances is crucial in this sector. These films ensure that product information, branding, and regulatory details remain legible and intact throughout the product's lifecycle. The aesthetic appeal of transparent thermal printing films is particularly valued in this industry, as it allows for elegant and discreet labeling that complements the product's design. In the Pharmaceutical sector, direct thermal printing films are used for labeling medications, medical devices, and other healthcare products. The need for accurate and reliable labeling is paramount in this industry, where even minor errors can have significant consequences. Direct thermal printing films provide a reliable solution for producing clear and legible labels that can include critical information such as dosage instructions, expiration dates, and batch numbers. The durability of these films ensures that the information remains intact even in challenging environments, such as refrigerated storage or during transportation. The Food and Beverage industry also relies heavily on direct thermal printing films for labeling and packaging. These films are used to produce labels that can withstand exposure to moisture, temperature fluctuations, and handling during distribution. The ability to produce high-quality, durable labels that can include important information such as nutritional facts, ingredients, and expiration dates is essential in this sector. The use of direct thermal printing films helps ensure that consumers have access to the information they need to make informed purchasing decisions. Luggage Tags are another area where direct thermal printing films are widely used. The durability and reliability of these films make them ideal for producing luggage tags that can withstand the rigors of travel. The ability to produce clear and legible tags that include important information such as passenger details, flight information, and destination is crucial in this application. Direct thermal printing films ensure that this information remains intact and readable throughout the journey, reducing the risk of lost or misdirected luggage. In addition to these specific applications, direct thermal printing films are used in a variety of other sectors, including retail, logistics, and manufacturing. The versatility and reliability of these films make them suitable for a wide range of labeling and packaging needs. As businesses continue to seek efficient and cost-effective solutions for their printing needs, the demand for direct thermal printing films is expected to grow. The ongoing development of new materials and technologies is helping to expand the range of applications for these films, ensuring that they remain a vital component of modern business operations.

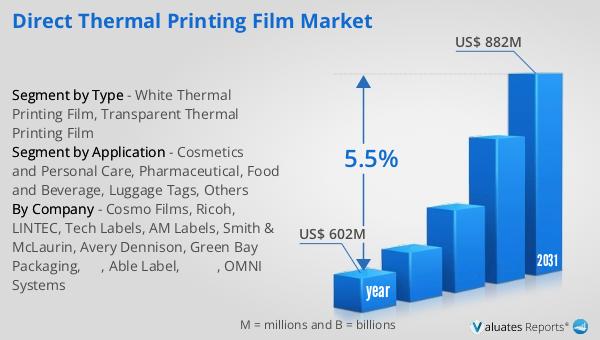

Global Direct Thermal Printing Film Market Outlook:

The global market for Direct Thermal Printing Film was valued at $602 million in 2024 and is anticipated to grow to a revised size of $882 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.5% during the forecast period. This growth is driven by the increasing demand for efficient and cost-effective printing solutions across various industries. Major manufacturers in the Direct Thermal Printing Film market include Cosmo Films, Ricoh, LINTEC, Avery Dennison, and Guangdong Guanhao High-Tech. These companies were among the top five in terms of global market share by revenue in 2024, collectively accounting for 35% of the total market. Their dominance in the market is attributed to their extensive product offerings, strong distribution networks, and continuous investment in research and development. These manufacturers are focused on enhancing the performance and versatility of their products to meet the evolving needs of their customers. As the market continues to grow, these companies are well-positioned to capitalize on new opportunities and maintain their leadership positions. The competitive landscape of the Direct Thermal Printing Film market is characterized by a mix of established players and emerging companies, each striving to innovate and differentiate their products. This dynamic environment is fostering the development of new materials and technologies, which are expected to drive further growth in the market. As businesses across various sectors continue to seek efficient and reliable printing solutions, the demand for Direct Thermal Printing Film is expected to remain strong, supporting the market's positive outlook.

| Report Metric | Details |

| Report Name | Direct Thermal Printing Film Market |

| Accounted market size in year | US$ 602 million |

| Forecasted market size in 2031 | US$ 882 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Cosmo Films, Ricoh, LINTEC, Tech Labels, AM Labels, Smith & McLaurin, Avery Dennison, Green Bay Packaging, 碧彩, Able Label, 冠豪高新, OMNI Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |