What is Global 3D Printing Pharmaceuticals Market?

The Global 3D Printing Pharmaceuticals Market is an innovative and rapidly evolving sector within the pharmaceutical industry. This market leverages 3D printing technology to create customized medications, offering significant advantages over traditional drug manufacturing methods. By using 3D printers, pharmaceutical companies can produce drugs with precise dosages tailored to individual patient needs, enhancing treatment efficacy and reducing side effects. This technology also allows for the creation of complex drug formulations that were previously difficult or impossible to manufacture. The market is driven by the increasing demand for personalized medicine, advancements in 3D printing technology, and the growing prevalence of chronic diseases that require long-term medication management. Additionally, 3D printing in pharmaceuticals can streamline the drug development process, reduce production costs, and minimize waste, making it an attractive option for both manufacturers and healthcare providers. As the technology continues to advance, the Global 3D Printing Pharmaceuticals Market is expected to play a crucial role in the future of personalized healthcare and precision medicine.

FDM, SLS, PB, SLA, SSE, DPE, DOD, MDD, MED in the Global 3D Printing Pharmaceuticals Market:

Fused Deposition Modeling (FDM) is one of the most common 3D printing techniques used in the pharmaceutical industry. It involves the extrusion of thermoplastic materials to create drug formulations layer by layer. This method is particularly useful for producing oral dosage forms with complex geometries and controlled release profiles. Selective Laser Sintering (SLS) uses a laser to fuse powdered materials, allowing for the creation of highly detailed and precise drug delivery systems. Powder Bed (PB) printing, also known as binder jetting, involves the deposition of a liquid binder onto a bed of powder, which then solidifies to form the desired structure. This technique is ideal for producing porous tablets that dissolve quickly in the body. Stereolithography (SLA) uses a UV laser to cure liquid resin into solid structures, making it suitable for creating intricate drug delivery devices. Semi-Solid Extrusion (SSE) involves the extrusion of semi-solid materials to form drug formulations, offering advantages in terms of dosage accuracy and stability. Direct Powder Extrusion (DPE) is a technique where powdered drugs are directly extruded to form solid dosage forms, providing a high degree of control over drug release rates. Drop on Demand (DOD) printing involves the precise deposition of small droplets of drug-containing solutions onto a substrate, allowing for the creation of multi-layered drug formulations. Melt Drop Deposition (MDD) uses heat to melt drug-containing materials, which are then deposited layer by layer to form solid dosage forms. Multi-Extrusion Deposition (MED) involves the simultaneous extrusion of multiple materials to create complex drug formulations with varying release profiles. Each of these 3D printing techniques offers unique advantages and can be tailored to meet specific pharmaceutical needs, making them invaluable tools in the development of personalized medications.

Personalized Pharmacy, Nutrients in the Global 3D Printing Pharmaceuticals Market:

The usage of 3D printing in the Global 3D Printing Pharmaceuticals Market extends to several critical areas, including personalized pharmacy and nutrients. In personalized pharmacy, 3D printing technology allows for the creation of customized medications tailored to individual patient needs. This is particularly beneficial for patients with unique medical conditions or those who require specific dosages that are not available in standard drug formulations. By using 3D printing, pharmacists can produce medications with precise dosages, shapes, and release profiles, ensuring optimal therapeutic outcomes. This level of customization can also improve patient adherence to medication regimens, as the drugs can be designed to be more palatable or easier to swallow. Additionally, 3D printing enables the combination of multiple drugs into a single dosage form, reducing the number of pills a patient needs to take and simplifying complex medication schedules. In the area of nutrients, 3D printing technology can be used to create personalized dietary supplements and fortified foods. This is particularly useful for individuals with specific nutritional needs, such as athletes, elderly patients, or those with dietary restrictions. By customizing the composition and dosage of nutrients, 3D printing can help ensure that individuals receive the exact nutrients they need to maintain optimal health. Furthermore, 3D printed nutrients can be designed to enhance bioavailability and absorption, improving their effectiveness. Overall, the application of 3D printing in personalized pharmacy and nutrients represents a significant advancement in the field of personalized medicine, offering tailored solutions that can improve patient outcomes and overall health.

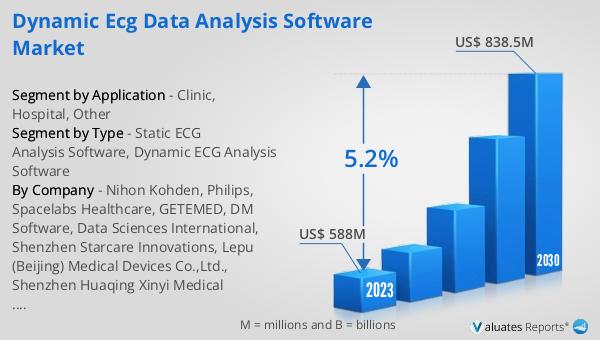

Global 3D Printing Pharmaceuticals Market Outlook:

The global 3D Printing Pharmaceuticals market was valued at US$ 309.3 million in 2023 and is projected to reach US$ 532.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 8.1% during the forecast period from 2024 to 2030. In comparison, the global pharmaceutical market was valued at 1475 billion USD in 2022 and is expected to grow at a CAGR of 5% over the next six years. The chemical drug market, a significant segment within the broader pharmaceutical industry, was estimated to increase from 1005 billion USD in 2018 to 1094 billion USD in 2022. This data highlights the rapid growth and increasing importance of the 3D Printing Pharmaceuticals market within the larger pharmaceutical landscape. The ability to produce customized medications and complex drug formulations using 3D printing technology is driving this growth, as it offers significant advantages over traditional drug manufacturing methods. As the demand for personalized medicine continues to rise, the 3D Printing Pharmaceuticals market is poised to play a crucial role in meeting this need, providing tailored solutions that enhance patient care and treatment outcomes.

| Report Metric | Details |

| Report Name | 3D Printing Pharmaceuticals Market |

| Accounted market size in 2023 | US$ 309.3 million |

| Forecasted market size in 2030 | US$ 532.6 million |

| CAGR | 8.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Triastek,Inc., Aprecia, AstraZeneca, FabRx, Multiply Labs, DiHeSys, Merck, Merck KGaA, TNO, Therics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |