What is Waste Plastic Recycling and Processing - Global Market?

Waste plastic recycling and processing is a crucial component of the global market aimed at addressing the environmental challenges posed by plastic waste. This market involves the collection, sorting, and reprocessing of plastic waste into reusable materials, thereby reducing the need for virgin plastic production and minimizing environmental pollution. The process begins with the collection of plastic waste from various sources, including households, industries, and commercial establishments. Once collected, the waste is sorted based on the type of plastic, such as PET, PP, HDPE, and LDPE, among others. This sorting is essential because different types of plastics require different recycling processes. After sorting, the plastics undergo processing, which can be mechanical or chemical, to convert them into reusable materials. Mechanical processing involves shredding and melting the plastics to form new products, while chemical recycling breaks down the plastics into their chemical components for reuse. The global market for waste plastic recycling and processing is driven by increasing environmental awareness, stringent government regulations, and the growing demand for sustainable materials. As a result, this market is expected to grow significantly, contributing to a more sustainable and environmentally friendly future.

Mechanical Processing, Chemical Recycling in the Waste Plastic Recycling and Processing - Global Market:

Mechanical processing and chemical recycling are two primary methods used in the waste plastic recycling and processing market. Mechanical processing is the most common method and involves physically breaking down plastic waste into smaller pieces, which are then melted and reformed into new products. This method is cost-effective and widely used for recycling common plastics like PET, PP, HDPE, and LDPE. The process begins with the collection and sorting of plastic waste, followed by cleaning to remove any contaminants. The cleaned plastics are then shredded into small flakes, which are melted and extruded into new products such as bottles, containers, and packaging materials. Mechanical processing is advantageous because it is relatively simple and does not require complex chemical reactions. However, it has limitations, such as the degradation of plastic quality after multiple recycling cycles. On the other hand, chemical recycling involves breaking down plastic waste into its chemical components, which can then be used to produce new plastics or other chemical products. This method is more complex and expensive than mechanical processing but offers the advantage of producing high-quality recycled materials. Chemical recycling can handle a wider range of plastics, including those that are difficult to recycle mechanically. The process involves depolymerization, where the long polymer chains in plastics are broken down into monomers or other chemical compounds. These monomers can then be purified and repolymerized to form new plastics with properties similar to virgin materials. Chemical recycling is still in its early stages of development, but it holds great potential for the future of plastic recycling. Both mechanical processing and chemical recycling play a crucial role in the global market for waste plastic recycling and processing, helping to reduce plastic waste and promote sustainability.

PET, PP, HDPE, LDPE, Other Plastic in the Waste Plastic Recycling and Processing - Global Market:

The global market for waste plastic recycling and processing plays a significant role in the recycling of various types of plastics, including PET, PP, HDPE, LDPE, and other plastics. PET, or polyethylene terephthalate, is commonly used in the production of beverage bottles and food containers. It is highly recyclable and can be processed through mechanical recycling to produce new bottles, fibers, and packaging materials. The recycling of PET is well-established, and it is one of the most widely recycled plastics globally. PP, or polypropylene, is used in a variety of applications, including packaging, automotive parts, and textiles. It can be recycled through mechanical processing to produce new products such as automotive components, containers, and fibers. HDPE, or high-density polyethylene, is used in the production of milk jugs, detergent bottles, and piping. It is highly recyclable and can be processed through mechanical recycling to produce new bottles, pipes, and plastic lumber. LDPE, or low-density polyethylene, is used in the production of plastic bags, films, and containers. It is more challenging to recycle than HDPE due to its lower density and flexibility, but it can still be processed through mechanical recycling to produce new films and bags. Other plastics, such as polystyrene and PVC, are more challenging to recycle due to their chemical composition and the presence of additives. However, advancements in chemical recycling technologies are making it possible to recycle these plastics more effectively. The global market for waste plastic recycling and processing is essential for reducing plastic waste and promoting the circular economy by converting plastic waste into valuable resources.

Waste Plastic Recycling and Processing - Global Market Outlook:

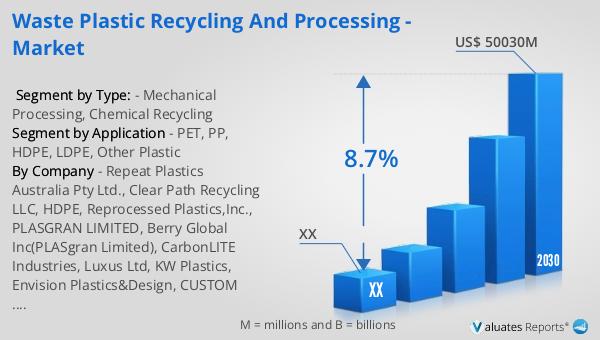

In 2023, the global market for waste plastic recycling and processing was valued at approximately US$ 27.9 billion. This market is projected to experience significant growth, reaching an estimated value of US$ 50.03 billion by 2030. This growth represents a compound annual growth rate (CAGR) of 8.7% during the forecast period from 2024 to 2030. The increasing awareness of environmental issues, coupled with stringent government regulations and the growing demand for sustainable materials, is driving the expansion of this market. As more industries and consumers recognize the importance of reducing plastic waste and promoting recycling, the demand for waste plastic recycling and processing is expected to rise. This market growth is also supported by technological advancements in recycling processes, which are making it more efficient and cost-effective to recycle various types of plastics. The global market for waste plastic recycling and processing is poised to play a crucial role in addressing the environmental challenges posed by plastic waste, contributing to a more sustainable and environmentally friendly future.

| Report Metric | Details |

| Report Name | Waste Plastic Recycling and Processing - Market |

| Forecasted market size in 2030 | US$ 50030 million |

| CAGR | 8.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Repeat Plastics Australia Pty Ltd., Clear Path Recycling LLC, HDPE, Reprocessed Plastics,Inc., PLASGRAN LIMITED, Berry Global Inc(PLASgran Limited), CarbonLITE Industries, Luxus Ltd, KW Plastics, Envision Plastics&Design, CUSTOM POLYMERS, Shanghai PRET Composites Company(Wellman Advanced Materials), Intco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |