What is Electric Welding Protective Masks - Global Market?

Electric welding protective masks are essential safety equipment designed to shield welders from the intense light, heat, and sparks generated during welding processes. These masks are crucial in preventing eye injuries, skin burns, and inhalation of harmful fumes. The global market for electric welding protective masks is driven by the increasing demand for welding activities across various industries, including construction, automotive, and manufacturing. As industries continue to expand and modernize, the need for effective protective gear becomes more pronounced. The market is characterized by a wide range of products, from basic protective masks to advanced models equipped with features like auto-darkening filters (ADF) that automatically adjust the lens shade based on the intensity of the welding arc. This adaptability not only enhances safety but also improves the welder's efficiency and comfort. The growing awareness about workplace safety and stringent regulations mandating the use of protective gear further propel the market's growth. Additionally, technological advancements in mask design and materials contribute to the development of more durable and user-friendly products, catering to the diverse needs of professional welders worldwide. As a result, the electric welding protective masks market is poised for significant growth in the coming years.

Ordinary Masks, Auto Darkening (ADF) Masks in the Electric Welding Protective Masks - Global Market:

Ordinary masks and auto-darkening (ADF) masks are two primary types of electric welding protective masks available in the global market, each serving distinct purposes and catering to different user preferences. Ordinary masks, often referred to as passive welding helmets, are the traditional choice for welders. These masks feature a fixed shade lens, typically made from tinted glass, which provides consistent protection against the bright light and harmful UV/IR radiation emitted during welding. While they are generally more affordable and straightforward in design, ordinary masks require the welder to lift the helmet frequently to inspect the workpiece, which can be cumbersome and time-consuming. Despite this limitation, they remain popular among hobbyists and in situations where budget constraints are a primary concern. On the other hand, auto-darkening (ADF) masks represent a significant advancement in welding safety technology. These masks are equipped with sensors that detect the welding arc's light intensity and automatically adjust the lens shade to provide optimal protection. This feature allows welders to keep the helmet in place throughout the welding process, enhancing productivity and reducing neck strain. ADF masks are particularly beneficial in environments where welders frequently switch between different types of welding or need to perform precision work. The convenience and enhanced safety offered by ADF masks have made them increasingly popular in professional settings, despite their higher cost compared to ordinary masks. The global market for electric welding protective masks is witnessing a growing preference for ADF masks, driven by the increasing emphasis on workplace safety and the demand for more efficient welding operations. Manufacturers are continually innovating to improve the performance and comfort of ADF masks, incorporating features such as adjustable sensitivity, delay controls, and lightweight materials. These advancements not only enhance the user experience but also contribute to the overall safety and productivity of welding operations. As industries continue to evolve and adopt new technologies, the demand for advanced protective gear like ADF masks is expected to rise, further shaping the landscape of the electric welding protective masks market.

Shipbuilding, Energy, Industrial, Automotive, Infrastructure Construction, Others in the Electric Welding Protective Masks - Global Market:

Electric welding protective masks play a vital role in various industries, ensuring the safety and efficiency of welding operations. In the shipbuilding industry, these masks are indispensable due to the extensive welding work required in constructing and repairing ships. The harsh marine environment and the need for precision in welding tasks make high-quality protective masks essential for shipbuilders. Similarly, in the energy sector, where welding is crucial for constructing and maintaining infrastructure such as pipelines, power plants, and refineries, electric welding protective masks are critical for safeguarding workers from the intense heat and light produced during welding. The industrial sector, encompassing manufacturing and fabrication, relies heavily on welding processes to create and assemble products. Here, electric welding protective masks are fundamental in protecting workers from potential hazards, ensuring compliance with safety regulations, and maintaining productivity. In the automotive industry, welding is a key component of vehicle manufacturing, from assembling frames to attaching components. Protective masks are essential for automotive welders to prevent injuries and ensure the quality of welds. Infrastructure construction, which includes building bridges, roads, and other public works, also demands the use of electric welding protective masks to protect workers from the dangers associated with welding in often challenging environments. Beyond these specific industries, electric welding protective masks find applications in various other sectors where welding is a common practice. This includes small-scale workshops, artistic metalworking, and maintenance and repair operations. The versatility and adaptability of these masks make them suitable for a wide range of welding tasks, from simple repairs to complex fabrication projects. As industries continue to grow and evolve, the demand for reliable and effective protective gear like electric welding masks is expected to increase, driven by the need to ensure worker safety and meet regulatory standards. The global market for electric welding protective masks is poised for growth as more industries recognize the importance of investing in high-quality safety equipment to protect their workforce and enhance operational efficiency.

Electric Welding Protective Masks - Global Market Outlook:

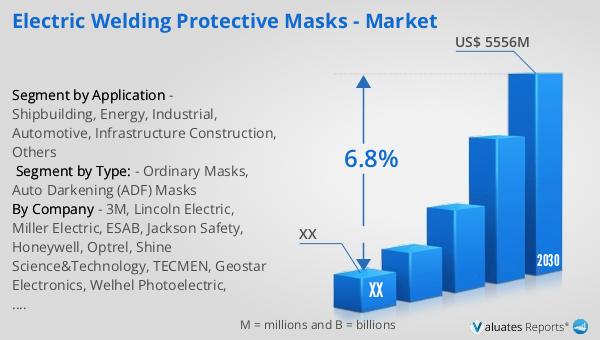

The global market for electric welding protective masks was valued at approximately $3,492 million in 2023. This market is projected to expand significantly, reaching an estimated size of $5,556 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.8% during the forecast period from 2024 to 2030. The North American segment of this market also shows promising potential, although specific figures for 2023 and 2030 are not provided. However, it is anticipated that the region will experience a steady growth rate throughout the forecast period. The increasing demand for welding activities across various industries, coupled with a heightened awareness of workplace safety, is driving the market's expansion. Technological advancements in mask design and materials are also contributing to the development of more durable and user-friendly products, catering to the diverse needs of professional welders worldwide. As industries continue to expand and modernize, the need for effective protective gear becomes more pronounced, further propelling the market's growth. The global market for electric welding protective masks is poised for significant growth in the coming years, driven by the increasing emphasis on workplace safety and the demand for more efficient welding operations.

| Report Metric | Details |

| Report Name | Electric Welding Protective Masks - Market |

| Forecasted market size in 2030 | US$ 5556 million |

| CAGR | 6.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3M, Lincoln Electric, Miller Electric, ESAB, Jackson Safety, Honeywell, Optrel, Shine Science&Technology, TECMEN, Geostar Electronics, Welhel Photoelectric, Goldland Industrial |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |