What is Global Reusable Stainless Steel Wet Film Thickness Gauge Market?

The Global Reusable Stainless Steel Wet Film Thickness Gauge Market is a specialized sector that focuses on the production and distribution of reusable stainless steel wet film thickness gauges. These gauges are precision tools used to measure the thickness of wet films, such as paint, varnish, and other coatings, before they dry. The importance of these gauges cannot be overstated as they play a crucial role in ensuring the quality and longevity of coatings. The global market for these gauges is vast and diverse, encompassing a wide range of industries and applications. However, the market is not without its challenges. Factors such as the high cost of stainless steel and the need for specialized training to use these gauges effectively can pose significant barriers to entry. Despite these challenges, the market continues to grow, driven by the increasing demand for high-quality coatings in industries such as automotive, aerospace, and construction.

Triangle, Square, Pentagon, Round, Other in the Global Reusable Stainless Steel Wet Film Thickness Gauge Market:

The Global Reusable Stainless Steel Wet Film Thickness Gauge Market can be segmented based on the shape of the gauges, namely Triangle, Square, Pentagon, Round, and Others. Each shape has its unique advantages and applications. Triangle gauges, for instance, are often used in applications where precision is paramount, such as in the aerospace industry. Square gauges, on the other hand, are typically used in applications where durability and ease of use are more important, such as in the construction industry. Pentagon gauges are versatile and can be used in a variety of applications, while round gauges are often used in applications where space is limited. Other shapes, such as oval or rectangular, are also available to cater to specific needs. The choice of shape depends on several factors, including the type of coating, the surface to be measured, and the specific requirements of the application.

Paint Thickness Measurement, Resin Thickness Measurement, Gel Coat Thickness Measurement, Others in the Global Reusable Stainless Steel Wet Film Thickness Gauge Market:

The Global Reusable Stainless Steel Wet Film Thickness Gauge Market finds its usage in several areas such as Paint Thickness Measurement, Resin Thickness Measurement, Gel Coat Thickness Measurement, among others. In Paint Thickness Measurement, these gauges are used to ensure that the paint is applied at the correct thickness, which is crucial for achieving the desired finish and durability. In Resin Thickness Measurement, the gauges are used to ensure that the resin is applied evenly and at the correct thickness, which is essential for the performance and longevity of the resin coating. In Gel Coat Thickness Measurement, the gauges are used to measure the thickness of the gel coat before it dries, which is critical for the appearance and durability of the finished product. In other applications, these gauges are used to measure the thickness of various other types of wet films, such as varnish, lacquer, and adhesive.

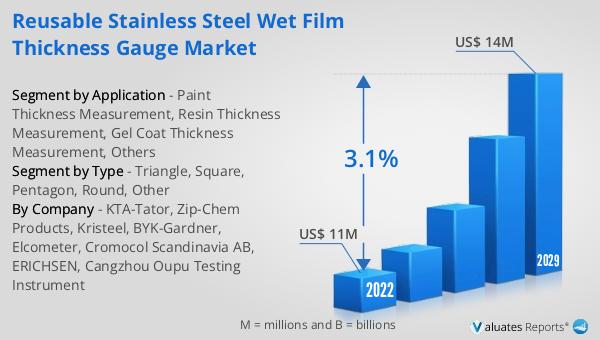

Global Reusable Stainless Steel Wet Film Thickness Gauge Market Outlook:

According to a recent survey, the Global Reusable Stainless Steel Wet Film Thickness Gauge Market is expected to experience steady growth over the next few years. The market, which was valued at US$ 11 million in 2022, is projected to reach a value of US$ 14 million by 2029. This represents a Compound Annual Growth Rate (CAGR) of 3.1% during the period from 2023 to 2029. This growth can be attributed to several factors, including the increasing demand for high-quality coatings in various industries, the ongoing technological advancements in the field of coating thickness measurement, and the growing awareness about the importance of proper coating application. However, it's important to note that these projections are based on current market trends and conditions, and actual market performance may vary.

| Report Metric | Details |

| Report Name | Reusable Stainless Steel Wet Film Thickness Gauge Market |

| Accounted market size in 2022 | US$ 11 million |

| Forecasted market size in 2029 | US$ 14 million |

| CAGR | 3.1% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KTA-Tator, Zip-Chem Products, Kristeel, BYK-Gardner, Elcometer, Cromocol Scandinavia AB, ERICHSEN, Cangzhou Oupu Testing Instrument |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |