What is Global OnSite Nitrogen Generation System Market?

The Global OnSite Nitrogen Generation System Market is a vast and dynamic field that encompasses a variety of technologies and applications. At its core, it refers to the systems used to generate nitrogen on-site, rather than relying on delivery from external sources. These systems are becoming increasingly popular due to their cost-effectiveness, reliability, and environmental benefits. They work by separating nitrogen from the air, providing a constant supply of pure, high-quality nitrogen. This is particularly useful in industries where nitrogen is a critical component, such as the food and beverage, pharmaceutical, and chemical sectors.

PSA Nitrogen Generator, Membrane Nitrogen Generator in the Global OnSite Nitrogen Generation System Market:

Two of the most common types of OnSite Nitrogen Generation Systems are PSA (Pressure Swing Adsorption) and Membrane Nitrogen Generators. PSA Nitrogen Generators work by pressurizing air in a vessel filled with carbon molecular sieve (CMS). Under pressure, the CMS selectively adsorbs oxygen and other trace gases, allowing nitrogen to pass through. On the other hand, Membrane Nitrogen Generators use a membrane to separate nitrogen from other gases in the air. The membrane has microscopic pores that allow smaller oxygen molecules to pass through, while larger nitrogen molecules are retained. Both systems have their own advantages and are chosen based on the specific requirements of the application.

Food & Beverage, Pharmaceutical, Chemical, Others in the Global OnSite Nitrogen Generation System Market:

The usage of OnSite Nitrogen Generation Systems is widespread across various industries. In the Food & Beverage industry, nitrogen is used to preserve freshness, prevent oxidation, and extend shelf life. In the Pharmaceutical industry, it's used in the production of medicines, to maintain sterile environments, and in packaging to protect products from moisture and oxygen. In the Chemical industry, nitrogen is used in various processes including as a blanketing gas to prevent explosions and as a purging gas to remove contaminants. Other industries also use nitrogen for various applications, such as in the production of electronics, in the automotive industry, and in the oil and gas industry.

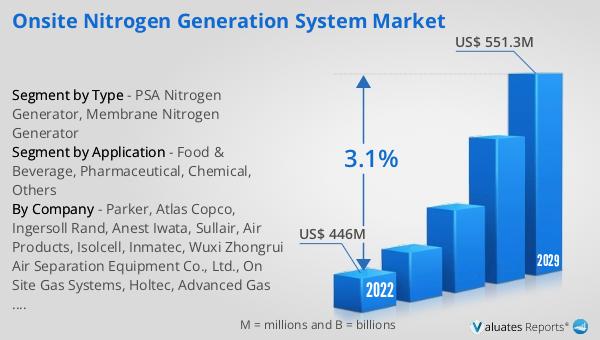

Global OnSite Nitrogen Generation System Market Outlook:

The future of the Global OnSite Nitrogen Generation System Market looks promising, as per a recent survey. The market, which was valued at US$ 446 million in 2022, is expected to grow to US$ 551.3 million by 2029. This represents a Compound Annual Growth Rate (CAGR) of 3.1% from 2023 to 2029. This growth can be attributed to the increasing demand for nitrogen in various industries, the cost-effectiveness of onsite generation compared to delivered nitrogen, and the environmental benefits of reducing the carbon footprint associated with nitrogen delivery.

| Report Metric | Details |

| Report Name | OnSite Nitrogen Generation System Market |

| Accounted market size in 2022 | US$ 446 million |

| Forecasted market size in 2029 | US$ 551.3 million |

| CAGR | 3.1% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Parker, Atlas Copco, Ingersoll Rand, Anest Iwata, Sullair, Air Products, Isolcell, Inmatec, Wuxi Zhongrui Air Separation Equipment Co., Ltd., On Site Gas Systems, Holtec, Advanced Gas Technologies, Compressed Air Systems, Maziak, MSS Nitrogen, Novair, Generon, Omega Air, Donaldson |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |