What is Global Automatic Bleeding Valves Market?

The Global Automatic Bleeding Valves Market is a specialized segment within the broader plumbing and HVAC (heating, ventilation, and air conditioning) industry. These valves are crucial components used to automatically release trapped air from heating systems, ensuring optimal performance and efficiency. When air accumulates in heating systems, it can cause blockages, reduce heat transfer efficiency, and lead to uneven heating. Automatic bleeding valves help to prevent these issues by allowing air to escape without manual intervention. This not only improves the efficiency of heating systems but also extends their lifespan by reducing wear and tear. The market for these valves is driven by the increasing demand for energy-efficient heating solutions, particularly in regions with cold climates. Additionally, the growing awareness of the benefits of maintaining optimal heating system performance is contributing to the market's expansion. As more industries and households seek to improve energy efficiency and reduce operational costs, the demand for automatic bleeding valves is expected to rise. These valves are available in various types and sizes to cater to different system requirements, making them a versatile solution for both residential and commercial applications.

Heating Type, Trace Type, Rapid Type, Combined Type in the Global Automatic Bleeding Valves Market:

In the Global Automatic Bleeding Valves Market, there are several types of valves designed to meet specific needs and applications. The Heating Type valves are primarily used in residential and commercial heating systems. These valves are designed to automatically release trapped air from radiators and other heating components, ensuring efficient heat distribution and preventing issues such as cold spots or noisy pipes. By maintaining optimal air levels, Heating Type valves help to improve the overall performance of heating systems, reduce energy consumption, and extend the lifespan of the equipment. Trace Type valves, on the other hand, are used in more specialized applications where precise control of air release is required. These valves are often employed in industrial settings where maintaining specific pressure levels is crucial for system performance. Trace Type valves are designed to handle high-pressure environments and are typically made from durable materials to withstand harsh conditions. Rapid Type valves are designed for quick and efficient air release, making them ideal for systems that require frequent bleeding. These valves are often used in applications where rapid changes in pressure or temperature occur, such as in certain industrial processes or high-performance heating systems. Rapid Type valves are engineered to respond quickly to changes in system conditions, ensuring that air is released promptly to maintain optimal performance. Combined Type valves offer a versatile solution by integrating features from multiple valve types. These valves are designed to provide comprehensive air release capabilities, making them suitable for a wide range of applications. Combined Type valves are often used in complex systems where different types of air release are required, such as in large commercial buildings or industrial facilities. By offering a combination of features, these valves provide a flexible and efficient solution for maintaining system performance and efficiency. Each type of valve in the Global Automatic Bleeding Valves Market is designed to address specific challenges and requirements, ensuring that systems operate smoothly and efficiently. As the demand for energy-efficient and reliable heating solutions continues to grow, the market for these valves is expected to expand, offering a range of options to meet the diverse needs of consumers and industries.

Oil & Gas, Chemical Industry, Power Industry, Others in the Global Automatic Bleeding Valves Market:

The Global Automatic Bleeding Valves Market finds extensive usage across various industries, including Oil & Gas, Chemical Industry, Power Industry, and others. In the Oil & Gas sector, these valves play a critical role in maintaining the efficiency and safety of heating systems used in exploration and production activities. The harsh conditions and remote locations of many oil and gas operations make it essential to have reliable and efficient heating systems. Automatic bleeding valves help to ensure that these systems operate smoothly by releasing trapped air, preventing blockages, and reducing the risk of equipment failure. In the Chemical Industry, automatic bleeding valves are used to maintain optimal performance in heating and cooling systems that are critical for various chemical processes. These valves help to ensure that the systems operate efficiently by preventing air accumulation, which can lead to uneven heating or cooling and affect the quality of chemical reactions. By maintaining consistent temperature and pressure levels, automatic bleeding valves contribute to the overall efficiency and safety of chemical processes. In the Power Industry, automatic bleeding valves are used in heating systems that are essential for power generation and distribution. These valves help to ensure that the systems operate efficiently by releasing trapped air, preventing blockages, and reducing the risk of equipment failure. By maintaining optimal performance, automatic bleeding valves contribute to the overall efficiency and reliability of power generation and distribution systems. In addition to these industries, automatic bleeding valves are also used in various other applications, including residential and commercial heating systems, HVAC systems, and industrial processes. The versatility and efficiency of these valves make them an essential component in maintaining optimal performance and efficiency across a wide range of applications. As the demand for energy-efficient and reliable heating solutions continues to grow, the usage of automatic bleeding valves is expected to expand across various industries, offering a range of options to meet the diverse needs of consumers and industries.

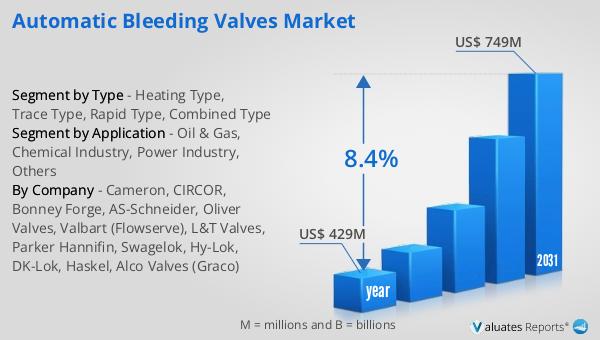

Global Automatic Bleeding Valves Market Outlook:

The global market for Automatic Bleeding Valves was valued at approximately $429 million in 2024. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach a revised size of around $749 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.4% during the forecast period. The increasing demand for energy-efficient heating solutions, coupled with the growing awareness of the benefits of maintaining optimal heating system performance, is driving this market expansion. Automatic bleeding valves are becoming increasingly popular in both residential and commercial applications due to their ability to improve system efficiency and reduce operational costs. As more industries and households seek to enhance energy efficiency and reduce their carbon footprint, the demand for these valves is expected to rise. The market's growth is also supported by technological advancements and innovations in valve design, which are making these products more efficient and reliable. With the ongoing focus on sustainability and energy conservation, the Global Automatic Bleeding Valves Market is poised for continued growth and development in the coming years.

| Report Metric | Details |

| Report Name | Automatic Bleeding Valves Market |

| Accounted market size in year | US$ 429 million |

| Forecasted market size in 2031 | US$ 749 million |

| CAGR | 8.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Cameron, CIRCOR, Bonney Forge, AS-Schneider, Oliver Valves, Valbart (Flowserve), L&T Valves, Parker Hannifin, Swagelok, Hy-Lok, DK-Lok, Haskel, Alco Valves (Graco) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |