What is Global Specialty Valves Market?

The Global Specialty Valves Market is a crucial segment within the broader industrial valves industry, focusing on valves designed for specific applications and environments. These valves are engineered to handle unique challenges such as extreme temperatures, high pressure, corrosive materials, and precise flow control. Specialty valves are essential in industries where standard valves may not suffice due to the demanding conditions. They are used in various sectors, including oil and gas, power generation, water treatment, and chemical processing, among others. The market for these valves is driven by the need for efficient and reliable flow control solutions that can enhance operational efficiency and safety. As industries continue to evolve and face new challenges, the demand for advanced specialty valves is expected to grow. This market is characterized by continuous innovation, with manufacturers investing in research and development to create valves that meet the specific needs of their clients. The global specialty valves market is a dynamic and competitive landscape, with numerous players striving to offer the best solutions to their customers. As a result, it plays a vital role in ensuring the smooth operation of critical industrial processes worldwide.

Ball Valves, Butterfly Valves, Diaphragm Valves, Other in the Global Specialty Valves Market:

Ball valves are a type of specialty valve that use a spherical disc to control the flow of liquids and gases. They are known for their durability and ability to provide a tight seal, making them ideal for applications where leakage is a concern. Ball valves are commonly used in industries such as oil and gas, chemical processing, and water treatment. Their design allows for quick and easy operation, often requiring only a quarter turn to open or close. This makes them highly efficient and reliable for controlling flow in various systems. Butterfly valves, on the other hand, use a rotating disc to regulate flow. They are lightweight and compact, making them suitable for applications where space is limited. Butterfly valves are often used in water distribution, HVAC systems, and food processing industries. They offer a cost-effective solution for flow control, especially in large diameter pipes. Diaphragm valves are designed with a flexible diaphragm that can be raised or lowered to control flow. These valves are particularly useful in applications involving corrosive or viscous fluids, as the diaphragm provides a barrier between the fluid and the valve components. Diaphragm valves are commonly used in the pharmaceutical, food and beverage, and chemical industries. Other types of specialty valves include gate valves, globe valves, and check valves, each with their unique design and functionality. Gate valves are used to start or stop the flow of fluid, while globe valves are used for regulating flow. Check valves, on the other hand, allow fluid to flow in one direction only, preventing backflow. Each type of valve has its specific applications and advantages, making them indispensable in various industrial processes. The global specialty valves market is diverse, with each type of valve serving a critical role in ensuring the efficient and safe operation of industrial systems.

Oil & Gas, Power Generation, Water Treatment, Chemical, Others in the Global Specialty Valves Market:

The Global Specialty Valves Market finds extensive usage in various industries, each with its unique requirements and challenges. In the oil and gas industry, specialty valves are crucial for managing the flow of crude oil, natural gas, and other hydrocarbons. These valves are designed to withstand high pressure and extreme temperatures, ensuring safe and efficient operations in upstream, midstream, and downstream processes. They are used in drilling rigs, pipelines, refineries, and storage facilities, where precise flow control is essential to prevent leaks and ensure safety. In power generation, specialty valves play a vital role in controlling the flow of steam, water, and other fluids within power plants. They are used in boilers, turbines, and cooling systems to regulate pressure and temperature, ensuring optimal performance and efficiency. The ability to handle high pressure and temperature makes these valves indispensable in both conventional and renewable energy power plants. Water treatment facilities also rely heavily on specialty valves to manage the flow of water and chemicals used in the treatment process. These valves are essential for controlling the flow of water through filtration, disinfection, and distribution systems. They help ensure the safe and efficient operation of water treatment plants, providing clean and safe water for consumption and industrial use. In the chemical industry, specialty valves are used to handle corrosive and hazardous materials. They are designed to provide a high level of safety and reliability, preventing leaks and ensuring the safe handling of chemicals. These valves are used in various processes, including mixing, separation, and storage, where precise flow control is critical. Other industries that utilize specialty valves include pharmaceuticals, food and beverage, and pulp and paper. Each of these industries has specific requirements for flow control, and specialty valves are designed to meet these needs. The versatility and reliability of specialty valves make them an essential component in a wide range of industrial applications, ensuring the safe and efficient operation of critical processes.

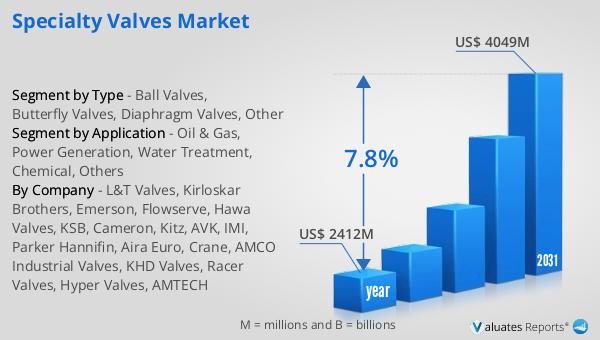

Global Specialty Valves Market Outlook:

The global market for specialty valves was valued at $2,412 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $4,049 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.8% over the forecast period. This upward trend in the market is driven by the increasing demand for efficient and reliable flow control solutions across various industries. As industries continue to evolve and face new challenges, the need for advanced specialty valves that can handle extreme conditions and provide precise flow control is expected to rise. The market's growth is also fueled by technological advancements and innovations in valve design and materials, which enhance the performance and durability of specialty valves. Manufacturers are investing in research and development to create valves that meet the specific needs of their clients, further driving the market's expansion. The global specialty valves market is a dynamic and competitive landscape, with numerous players striving to offer the best solutions to their customers. As a result, it plays a vital role in ensuring the smooth operation of critical industrial processes worldwide. The projected growth of the market highlights the increasing importance of specialty valves in various industries and their contribution to enhancing operational efficiency and safety.

| Report Metric | Details |

| Report Name | Specialty Valves Market |

| Accounted market size in year | US$ 2412 million |

| Forecasted market size in 2031 | US$ 4049 million |

| CAGR | 7.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | L&T Valves, Kirloskar Brothers, Emerson, Flowserve, Hawa Valves, KSB, Cameron, Kitz, AVK, IMI, Parker Hannifin, Aira Euro, Crane, AMCO Industrial Valves, KHD Valves, Racer Valves, Hyper Valves, AMTECH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |