What is Global Wire Bonding Capillary (Capillaries) Market?

The Global Wire Bonding Capillary Market is a specialized segment within the semiconductor industry that focuses on the production and distribution of capillaries used in wire bonding processes. Wire bonding is a crucial step in semiconductor manufacturing, where tiny wires are used to connect semiconductor chips to their external circuits. Capillaries, typically made from materials like ceramic or tungsten carbide, are essential tools in this process, guiding the wire and ensuring precise placement and bonding. The market for these capillaries is driven by the growing demand for semiconductors across various industries, including consumer electronics, automotive, and telecommunications. As technology advances, the need for more efficient and reliable wire bonding solutions increases, propelling the growth of the wire bonding capillary market. Companies in this market are continuously innovating to develop capillaries that can handle finer wires and more complex bonding requirements, catering to the evolving needs of the semiconductor industry. The market is characterized by a mix of established players and new entrants, all striving to offer high-quality products that meet the stringent demands of modern semiconductor manufacturing.

Cu Wire Bonding Capillaries, Au Wire Bonding Capillaries, Ag Wire Bonding Capillaries, Others in the Global Wire Bonding Capillary (Capillaries) Market:

Cu Wire Bonding Capillaries, Au Wire Bonding Capillaries, Ag Wire Bonding Capillaries, and others are integral components of the Global Wire Bonding Capillary Market, each serving distinct purposes based on the type of wire used in the bonding process. Cu (Copper) Wire Bonding Capillaries are designed to handle copper wires, which are increasingly popular due to their cost-effectiveness and excellent electrical conductivity. Copper wire bonding is often used in applications where cost reduction is a priority without compromising performance. These capillaries must be robust enough to handle the harder nature of copper compared to gold, requiring precise engineering to ensure reliability and efficiency. Au (Gold) Wire Bonding Capillaries, on the other hand, are tailored for gold wires, which have been the traditional choice in wire bonding due to their superior conductivity and resistance to oxidation. Gold wire bonding is preferred in high-reliability applications, such as aerospace and medical devices, where performance and longevity are critical. The capillaries for gold wire bonding are designed to accommodate the softer nature of gold, ensuring smooth and consistent bonding. Ag (Silver) Wire Bonding Capillaries cater to silver wires, which offer a balance between the cost-effectiveness of copper and the performance of gold. Silver wire bonding is gaining traction in applications where both cost and performance are important considerations. The capillaries for silver wires must be carefully designed to handle the unique properties of silver, ensuring optimal bonding results. In addition to these, there are other specialized capillaries designed for niche applications or emerging wire materials. These may include capillaries for aluminum wires or other innovative materials being explored in the semiconductor industry. Each type of capillary is engineered to meet specific requirements, such as wire diameter, bonding force, and temperature tolerance, ensuring compatibility with the intended wire material and application. The diversity in wire bonding capillaries reflects the varied needs of the semiconductor industry, where different applications demand different wire materials and bonding techniques. As the industry continues to evolve, the development of new capillary designs and materials will be crucial in supporting the advancement of semiconductor technology.

General Semiconductor & LED, Automotive & Industrial, Advanced Packaging in the Global Wire Bonding Capillary (Capillaries) Market:

The usage of Global Wire Bonding Capillary Market products spans several key areas, including General Semiconductor & LED, Automotive & Industrial, and Advanced Packaging. In the General Semiconductor & LED sector, wire bonding capillaries are essential for manufacturing a wide range of electronic components, from microprocessors to LED chips. These components require precise and reliable connections to function correctly, and wire bonding capillaries play a critical role in achieving this. The demand for semiconductors and LEDs is driven by the proliferation of electronic devices, smart technologies, and energy-efficient lighting solutions, all of which rely on high-quality wire bonding processes. In the Automotive & Industrial sectors, wire bonding capillaries are used in the production of electronic systems that power modern vehicles and industrial machinery. As vehicles become more advanced, with features like autonomous driving and enhanced connectivity, the need for reliable semiconductor components increases. Wire bonding capillaries ensure that these components are manufactured to the highest standards, supporting the performance and safety of automotive systems. Similarly, in industrial applications, where machinery and equipment are becoming more automated and interconnected, the demand for robust semiconductor components is on the rise. Wire bonding capillaries are crucial in producing these components, ensuring they can withstand the harsh conditions often encountered in industrial environments. Advanced Packaging is another area where wire bonding capillaries are extensively used. As semiconductor devices become smaller and more complex, advanced packaging techniques are required to accommodate the increased functionality within limited space. Wire bonding capillaries are instrumental in these techniques, enabling the precise placement and connection of wires in densely packed semiconductor packages. This is particularly important in applications like smartphones, tablets, and other portable devices, where space is at a premium, and performance cannot be compromised. The use of wire bonding capillaries in these areas highlights their importance in the semiconductor manufacturing process, supporting the development of cutting-edge technologies across various industries.

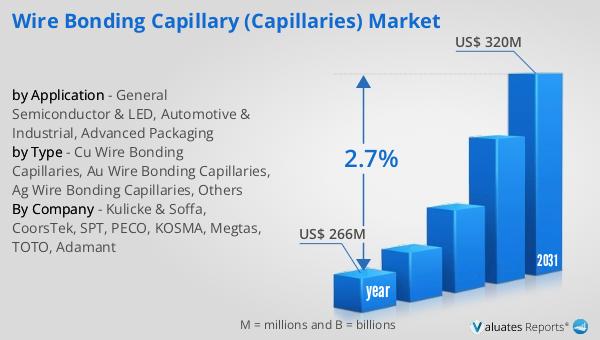

Global Wire Bonding Capillary (Capillaries) Market Outlook:

The global market for Wire Bonding Capillary Capillaries was valued at $266 million in 2024 and is anticipated to grow to a revised size of $320 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.7% over the forecast period. This growth trajectory underscores the increasing demand for wire bonding capillaries, driven by the expanding semiconductor industry and the continuous advancements in technology. As industries such as consumer electronics, automotive, and telecommunications continue to evolve, the need for efficient and reliable wire bonding solutions becomes more pronounced. The projected growth in the market size indicates a positive outlook for the wire bonding capillary industry, with opportunities for innovation and development in response to the changing needs of semiconductor manufacturing. Companies operating in this market are likely to focus on enhancing their product offerings, improving the performance and durability of their capillaries, and exploring new materials and designs to meet the diverse requirements of their customers. The steady growth rate also suggests a stable market environment, where established players and new entrants can compete and thrive, contributing to the overall advancement of the semiconductor industry.

| Report Metric | Details |

| Report Name | Wire Bonding Capillary (Capillaries) Market |

| Accounted market size in year | US$ 266 million |

| Forecasted market size in 2031 | US$ 320 million |

| CAGR | 2.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kulicke & Soffa, CoorsTek, SPT, PECO, KOSMA, Megtas, TOTO, Adamant |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |