What is Global Aluminum Nitride Electrostatic Chuck Market?

The Global Aluminum Nitride Electrostatic Chuck Market is a specialized segment within the semiconductor industry, focusing on the production and application of electrostatic chucks made from aluminum nitride. These chucks are critical components used in semiconductor manufacturing processes, particularly in the handling and processing of silicon wafers. Aluminum nitride is chosen for its excellent thermal conductivity and electrical insulation properties, making it ideal for maintaining the stability and precision required in semiconductor fabrication. The market for these chucks is driven by the increasing demand for semiconductors across various industries, including consumer electronics, automotive, and telecommunications. As technology advances, the need for more efficient and reliable semiconductor manufacturing equipment grows, further propelling the demand for aluminum nitride electrostatic chucks. The market is characterized by continuous innovation and development, with manufacturers striving to enhance the performance and durability of these components to meet the evolving needs of the semiconductor industry. The global reach of this market is evident, with significant contributions from regions such as Asia-Pacific, North America, and Europe, each playing a vital role in the production and consumption of these high-tech components.

Coulomb, Johnsen-Rahbek (JR) in the Global Aluminum Nitride Electrostatic Chuck Market:

Coulomb and Johnsen-Rahbek (JR) are two fundamental principles that underpin the operation of electrostatic chucks, particularly in the context of the Global Aluminum Nitride Electrostatic Chuck Market. The Coulomb principle is based on the electrostatic force generated between two surfaces when a voltage is applied. In the case of electrostatic chucks, this principle is utilized to hold semiconductor wafers securely in place during processing. The aluminum nitride material used in these chucks provides excellent thermal management, ensuring that the wafers remain stable and undistorted during high-temperature processes. The Coulomb-based chucks are known for their simplicity and reliability, making them a popular choice in various semiconductor manufacturing applications. On the other hand, the Johnsen-Rahbek (JR) effect is a more complex phenomenon that involves the generation of an electrostatic force through the interaction of a dielectric material with a conductive surface. This effect is particularly advantageous in applications where a stronger holding force is required, as it can provide a more robust grip on the wafer. The JR-based chucks are often used in advanced semiconductor manufacturing processes where precision and stability are paramount. The choice between Coulomb and JR-based chucks depends on the specific requirements of the manufacturing process, with each offering distinct advantages in terms of holding force, thermal management, and operational efficiency. The Global Aluminum Nitride Electrostatic Chuck Market is witnessing a growing interest in JR-based chucks due to their enhanced performance capabilities, particularly in the production of next-generation semiconductors. Manufacturers are investing in research and development to optimize the design and functionality of these chucks, ensuring they meet the stringent demands of modern semiconductor fabrication. As the semiconductor industry continues to evolve, the role of electrostatic chucks, whether based on Coulomb or JR principles, remains critical in achieving the precision and efficiency required in the production of high-performance electronic components. The ongoing advancements in this market are a testament to the importance of electrostatic chucks in the broader context of semiconductor manufacturing, highlighting their role as essential tools in the pursuit of technological innovation and excellence.

300 mm Wafers, 200 mm Wafers, Others in the Global Aluminum Nitride Electrostatic Chuck Market:

The Global Aluminum Nitride Electrostatic Chuck Market plays a crucial role in the semiconductor industry, particularly in the processing of 300 mm and 200 mm wafers, as well as other specialized applications. The use of aluminum nitride electrostatic chucks in the handling of 300 mm wafers is driven by the need for precision and stability in semiconductor manufacturing. These larger wafers are used in the production of high-performance semiconductors, and the chucks provide the necessary thermal management and electrostatic holding force to ensure accurate processing. The demand for 300 mm wafers is increasing as the semiconductor industry moves towards more advanced technologies, and the role of aluminum nitride electrostatic chucks is becoming increasingly important in meeting this demand. Similarly, the use of these chucks in the processing of 200 mm wafers is critical for maintaining the quality and efficiency of semiconductor production. The smaller size of these wafers requires precise handling and control, and the aluminum nitride chucks provide the necessary support to achieve this. The market for 200 mm wafers is driven by the demand for semiconductors in various applications, including consumer electronics and automotive, and the use of aluminum nitride electrostatic chucks is essential in meeting this demand. In addition to 300 mm and 200 mm wafers, the Global Aluminum Nitride Electrostatic Chuck Market also serves other specialized applications, such as the processing of compound semiconductors and advanced packaging technologies. These applications require high levels of precision and control, and the use of aluminum nitride electrostatic chucks is critical in achieving the desired outcomes. The versatility and reliability of these chucks make them an essential component in the semiconductor manufacturing process, and their role in supporting the production of high-performance electronic components cannot be overstated. As the semiconductor industry continues to evolve, the demand for aluminum nitride electrostatic chucks is expected to grow, driven by the need for more efficient and reliable manufacturing processes. The ongoing advancements in this market are a testament to the importance of these chucks in the broader context of semiconductor manufacturing, highlighting their role as essential tools in the pursuit of technological innovation and excellence.

Global Aluminum Nitride Electrostatic Chuck Market Outlook:

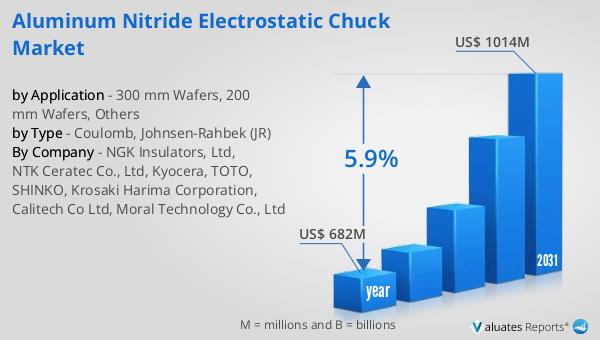

In 2024, the global market for Aluminum Nitride Electrostatic Chucks was valued at approximately $682 million, with projections indicating a growth to around $1,014 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.9% over the forecast period. The market dynamics vary significantly across different regions. In the Americas, sales reached $142.1 billion, marking a substantial year-on-year increase of 17.0%. This growth is indicative of the region's robust demand for semiconductor manufacturing equipment, driven by technological advancements and increased production capacities. In Europe, the market experienced a year-on-year growth of 12.6%, with sales totaling $53.8 billion. This growth can be attributed to the region's focus on innovation and the adoption of advanced manufacturing technologies. Meanwhile, Japan's market saw a 10.0% increase, with sales amounting to $48.1 billion, reflecting the country's strong presence in the semiconductor industry and its commitment to maintaining high standards of production. Conversely, the Asia-Pacific region, despite being the largest market, experienced a slight decline of 2.0%, with sales totaling $336.2 billion. This decrease may be due to various factors, including market saturation and economic fluctuations. Overall, the global market for Aluminum Nitride Electrostatic Chucks is poised for growth, driven by the increasing demand for semiconductors and the continuous advancements in manufacturing technologies.

| Report Metric | Details |

| Report Name | Aluminum Nitride Electrostatic Chuck Market |

| Accounted market size in year | US$ 682 million |

| Forecasted market size in 2031 | US$ 1014 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NGK Insulators, Ltd, NTK Ceratec Co., Ltd, Kyocera, TOTO, SHINKO, Krosaki Harima Corporation, Calitech Co Ltd, Moral Technology Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |