What is Global Atmosheric Wafer Transfer Robot Market?

The Global Atmospheric Wafer Transfer Robot Market is a specialized segment within the semiconductor manufacturing industry that focuses on the automation of wafer handling processes. These robots are designed to operate in atmospheric conditions, as opposed to vacuum environments, and are crucial for the efficient and precise transfer of semiconductor wafers between different processing stations. The demand for these robots is driven by the increasing complexity and miniaturization of semiconductor devices, which require highly accurate and contamination-free handling solutions. As semiconductor manufacturers strive to enhance production efficiency and yield, atmospheric wafer transfer robots play a pivotal role in streamlining operations and reducing human intervention. These robots are equipped with advanced sensors and control systems that ensure precise alignment and gentle handling of wafers, minimizing the risk of damage or contamination. The market for these robots is expanding as semiconductor fabrication facilities continue to upgrade their automation capabilities to meet the growing demand for advanced electronic devices. With technological advancements and the integration of artificial intelligence, atmospheric wafer transfer robots are becoming more sophisticated, offering enhanced performance and adaptability to various manufacturing environments. As a result, the Global Atmospheric Wafer Transfer Robot Market is poised for significant growth in the coming years.

Single Arm, Dual Arm in the Global Atmosheric Wafer Transfer Robot Market:

In the realm of the Global Atmospheric Wafer Transfer Robot Market, Single Arm and Dual Arm robots represent two distinct configurations that cater to different operational needs within semiconductor manufacturing. Single Arm robots are designed with a singular robotic arm that performs the task of transferring wafers between processing stations. These robots are typically employed in applications where space constraints are a concern or where the complexity of the transfer process is relatively low. Single Arm robots offer a cost-effective solution for wafer handling, providing reliable performance with a simpler mechanical design. They are often used in smaller fabrication facilities or in processes where the throughput requirements are moderate. On the other hand, Dual Arm robots are equipped with two robotic arms, allowing for simultaneous handling of multiple wafers or the execution of more complex transfer tasks. This configuration enhances the robot's flexibility and efficiency, making it suitable for high-volume production environments where speed and precision are paramount. Dual Arm robots can perform parallel operations, significantly reducing cycle times and increasing overall throughput. They are particularly advantageous in processes that require intricate handling or where wafers need to be transferred between multiple stations in quick succession. The choice between Single Arm and Dual Arm robots depends on various factors, including the specific requirements of the manufacturing process, the available space within the facility, and the desired level of automation. While Single Arm robots offer a more straightforward and economical solution, Dual Arm robots provide enhanced capabilities and are often preferred in cutting-edge semiconductor fabrication plants. As the semiconductor industry continues to evolve, the demand for both Single Arm and Dual Arm atmospheric wafer transfer robots is expected to grow, driven by the need for increased automation and efficiency in wafer handling processes. Manufacturers are continually innovating to improve the performance and adaptability of these robots, incorporating advanced technologies such as machine learning and real-time data analytics to optimize their operation. This ongoing development ensures that both Single Arm and Dual Arm robots remain integral components of modern semiconductor manufacturing, contributing to the industry's ability to meet the ever-increasing demand for advanced electronic devices.

Etching Equipment, Coating Equipment (PVD & CVD), Semiconductor Inspection Equipment, Track, Coater & Developer, Lithography Machine, Cleaning Equipment, Ion Implanter, CMP Equipment, Others Equipment in the Global Atmosheric Wafer Transfer Robot Market:

The Global Atmospheric Wafer Transfer Robot Market finds extensive application across various segments of semiconductor manufacturing, each with its unique requirements and challenges. In the realm of Etching Equipment, these robots are crucial for the precise handling of wafers as they undergo chemical processes to remove material and create intricate patterns. The robots ensure that wafers are transferred smoothly and accurately, minimizing the risk of contamination or damage during the etching process. Similarly, in Coating Equipment, which includes Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), atmospheric wafer transfer robots play a vital role in maintaining the integrity of wafers as they receive thin film coatings. The robots' ability to handle wafers delicately and consistently is essential for achieving uniform coatings and high-quality end products. In Semiconductor Inspection Equipment, these robots facilitate the movement of wafers through various inspection stages, ensuring that each wafer is thoroughly examined for defects or irregularities. The robots' precision and reliability are critical in maintaining the accuracy of inspection results, which are vital for quality control in semiconductor manufacturing. Track, Coater & Developer processes also benefit from the use of atmospheric wafer transfer robots, as they enable the seamless transfer of wafers between different stages of photolithography, coating, and development. The robots' ability to handle wafers with care and precision ensures that each step of the process is executed flawlessly, contributing to the overall efficiency and yield of the manufacturing operation. In Lithography Machines, where wafers are exposed to light patterns to create circuit designs, atmospheric wafer transfer robots ensure that wafers are positioned accurately and consistently, reducing the likelihood of errors or misalignments. Cleaning Equipment, which is essential for removing contaminants from wafers, also relies on these robots to handle wafers safely and efficiently, ensuring that they are thoroughly cleaned without damage. In Ion Implanters, where ions are embedded into wafers to alter their electrical properties, atmospheric wafer transfer robots facilitate the precise positioning and movement of wafers, ensuring that the implantation process is carried out accurately. Chemical Mechanical Planarization (CMP) Equipment, which is used to smooth and flatten wafer surfaces, also benefits from the use of these robots, as they ensure that wafers are handled gently and consistently throughout the process. Other Equipment within semiconductor manufacturing, such as annealing furnaces and metrology tools, also rely on atmospheric wafer transfer robots to optimize their operation and enhance overall production efficiency. The versatility and adaptability of these robots make them indispensable in modern semiconductor fabrication facilities, where they contribute to the seamless integration of various processes and the achievement of high-quality end products.

Global Atmosheric Wafer Transfer Robot Market Outlook:

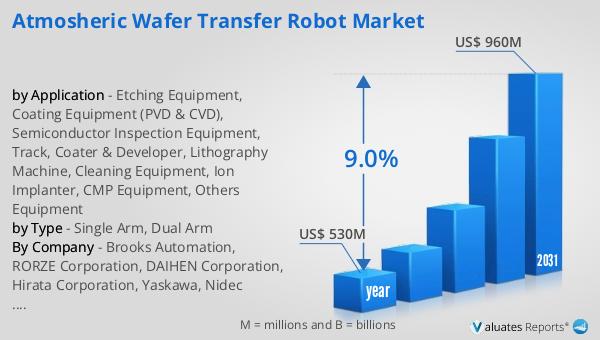

In 2024, the global market for Atmospheric Wafer Transfer Robots was valued at approximately $530 million. This market is anticipated to experience significant growth, reaching an estimated size of $960 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 9.0% over the forecast period. The increasing demand for advanced semiconductor devices and the need for efficient automation solutions in wafer handling processes are key drivers of this market expansion. Notably, regions such as North America, Europe, and Japan collectively hold a substantial market share, accounting for 23% of the global market. This indicates a strong presence and adoption of atmospheric wafer transfer robots in these regions, driven by the advanced semiconductor manufacturing capabilities and technological advancements prevalent there. The market's growth is further supported by the continuous innovation and development of more sophisticated robotic solutions that cater to the evolving needs of semiconductor fabrication facilities. As the industry progresses, the integration of cutting-edge technologies such as artificial intelligence and machine learning into these robots is expected to enhance their performance and adaptability, further fueling market growth. The increasing complexity of semiconductor devices and the demand for higher production efficiency are likely to drive the adoption of atmospheric wafer transfer robots across various regions, contributing to the overall expansion of the market.

| Report Metric | Details |

| Report Name | Atmosheric Wafer Transfer Robot Market |

| Accounted market size in year | US$ 530 million |

| Forecasted market size in 2031 | US$ 960 million |

| CAGR | 9.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Brooks Automation, RORZE Corporation, DAIHEN Corporation, Hirata Corporation, Yaskawa, Nidec (Genmark Automation), JEL Corporation, Kawasaki Robotics, Robostar, Robots and Design (RND), HYULIM Robot, RAONTEC Inc, KORO, Tazmo, Kensington Laboratories, EPSON Robots, Hine Automation, Moog Inc, Innovative Robotics, Staubli, isel Germany AG, Sanwa Engineering Corporation, Siasun Robot & Automation, HIWIN TECHNOLOGIES, He-Five LLC. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |