What is Global Inline Moisture Sensors Market?

The Global Inline Moisture Sensors Market is a specialized segment within the broader sensor market, focusing on devices that measure moisture levels in various materials during production processes. These sensors are crucial in industries where moisture content can significantly impact product quality, such as food processing, pharmaceuticals, and paper manufacturing. Inline moisture sensors are integrated directly into production lines, providing real-time data that helps in maintaining optimal moisture levels, ensuring product consistency, and reducing waste. The market for these sensors is driven by the increasing demand for automation and precision in manufacturing processes. As industries strive for higher efficiency and better quality control, the adoption of inline moisture sensors is expected to grow. These sensors not only enhance product quality but also contribute to cost savings by minimizing material wastage and energy consumption. The market is characterized by technological advancements, with manufacturers focusing on developing more accurate and reliable sensors that can operate in harsh industrial environments. Overall, the Global Inline Moisture Sensors Market plays a vital role in modern manufacturing, offering solutions that enhance productivity and product quality.

Contact Type, Non-contact Type in the Global Inline Moisture Sensors Market:

In the Global Inline Moisture Sensors Market, two primary types of sensors are utilized: contact type and non-contact type. Contact type moisture sensors require direct interaction with the material being measured. These sensors are typically embedded within the production line, making physical contact with the material to assess its moisture content. This type of sensor is often used in industries where the material is solid or semi-solid, such as in the production of paper, textiles, or certain food products. The advantage of contact type sensors is their ability to provide highly accurate moisture readings, as they measure the moisture content directly from the material. However, they may require regular maintenance and calibration to ensure accuracy, especially in environments where the material can cause wear and tear on the sensor. On the other hand, non-contact type moisture sensors operate without making physical contact with the material. These sensors use technologies such as infrared, microwave, or radio frequency to detect moisture levels from a distance. Non-contact sensors are particularly useful in situations where the material is moving rapidly, is sensitive to touch, or is in a state that makes contact impractical, such as powders or liquids. The primary advantage of non-contact sensors is their ability to measure moisture content without interfering with the material, thus reducing the risk of contamination or damage. They are also easier to maintain, as they do not suffer from wear and tear caused by direct contact. However, non-contact sensors may face challenges in terms of accuracy, especially in environments with high levels of dust or other particulates that can interfere with the sensor's readings. Both contact and non-contact moisture sensors have their unique advantages and limitations, and the choice between them often depends on the specific requirements of the production process. In some cases, a combination of both types may be used to achieve optimal results. For instance, a production line might use contact sensors for initial moisture readings and non-contact sensors for continuous monitoring. This approach allows manufacturers to benefit from the accuracy of contact sensors while also taking advantage of the non-intrusive nature of non-contact sensors. As technology continues to advance, the capabilities of both contact and non-contact moisture sensors are expected to improve, offering even greater precision and reliability in moisture measurement.

Industrial, Commercial in the Global Inline Moisture Sensors Market:

The usage of Global Inline Moisture Sensors Market spans across various sectors, with significant applications in both industrial and commercial areas. In industrial settings, inline moisture sensors are integral to processes where moisture content is a critical parameter. For example, in the food processing industry, maintaining the right moisture level is essential for product quality and shelf life. Inline moisture sensors help in monitoring and controlling moisture levels in real-time, ensuring that products meet quality standards and regulatory requirements. Similarly, in the paper and pulp industry, moisture content affects the strength and printability of paper. Inline moisture sensors provide continuous data that helps in optimizing the drying process, reducing energy consumption, and minimizing waste. In the commercial sector, inline moisture sensors are used in applications such as HVAC systems, where they help in maintaining optimal humidity levels for comfort and energy efficiency. These sensors are also employed in the construction industry, where they monitor moisture levels in building materials to prevent issues such as mold growth and structural damage. In agriculture, inline moisture sensors are used to assess soil moisture levels, aiding in efficient irrigation management and improving crop yields. The versatility of inline moisture sensors makes them valuable tools in various commercial applications, contributing to improved product quality, operational efficiency, and cost savings. Overall, the Global Inline Moisture Sensors Market plays a crucial role in enhancing productivity and quality across industrial and commercial sectors. By providing accurate and real-time moisture data, these sensors enable businesses to optimize their processes, reduce waste, and improve product quality. As industries continue to prioritize efficiency and sustainability, the demand for inline moisture sensors is expected to grow, driving further innovation and development in this market.

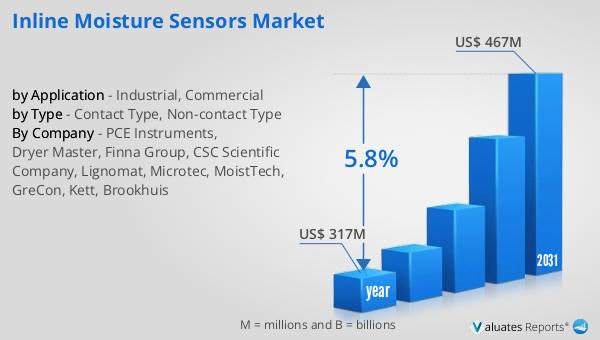

Global Inline Moisture Sensors Market Outlook:

The global market for Inline Moisture Sensors was valued at $317 million in 2024 and is anticipated to expand to a revised size of $467 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% during the forecast period. This growth trajectory underscores the increasing importance of moisture sensors in various industries, driven by the need for precision and efficiency in production processes. As manufacturers seek to enhance product quality and reduce waste, the adoption of inline moisture sensors is becoming more widespread. These sensors provide critical data that helps in maintaining optimal moisture levels, ensuring consistency and quality in the final product. The market's growth is also fueled by technological advancements, with companies investing in the development of more accurate and reliable sensors that can withstand harsh industrial environments. As a result, the Global Inline Moisture Sensors Market is poised for significant expansion, offering opportunities for innovation and growth in the coming years.

| Report Metric | Details |

| Report Name | Inline Moisture Sensors Market |

| Accounted market size in year | US$ 317 million |

| Forecasted market size in 2031 | US$ 467 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PCE Instruments, Dryer Master, Finna Group, CSC Scientific Company, Lignomat, Microtec, MoistTech, GreCon, Kett, Brookhuis |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |