What is Global MCPCB Market?

The Global MCPCB Market, or Metal Core Printed Circuit Board Market, is a specialized segment within the broader electronics industry. MCPCBs are unique because they incorporate a metal core, typically aluminum, copper, or an alloy, which helps in dissipating heat more efficiently than traditional PCBs. This feature is crucial for applications that generate significant heat, such as LED lighting, power converters, and automotive electronics. The metal core acts as a heat sink, drawing heat away from critical components and enhancing the overall reliability and lifespan of the device. The demand for MCPCBs is driven by the increasing need for efficient thermal management solutions in high-performance electronic devices. As technology advances, the complexity and power density of electronic components continue to rise, making effective heat dissipation more important than ever. This has led to a growing adoption of MCPCBs across various industries, including consumer electronics, automotive, telecommunications, and renewable energy. The market is characterized by continuous innovation, with manufacturers focusing on developing advanced materials and designs to meet the evolving needs of end-users. Overall, the Global MCPCB Market plays a vital role in supporting the development of high-performance, reliable electronic devices across multiple sectors.

Aluminum Core PCB, Cooper Core PCB, Alloys Core PCB in the Global MCPCB Market:

Aluminum Core PCBs are a popular choice within the Global MCPCB Market due to their excellent thermal conductivity and cost-effectiveness. These PCBs use an aluminum base as the core material, which provides a robust platform for heat dissipation. Aluminum Core PCBs are widely used in LED lighting applications, where efficient heat management is crucial to maintain the performance and longevity of the LEDs. The aluminum core helps in spreading the heat generated by the LEDs evenly across the board, preventing hotspots and ensuring consistent light output. Additionally, aluminum is a lightweight material, making it suitable for applications where weight is a concern, such as in automotive and aerospace industries. The use of aluminum also offers advantages in terms of mechanical stability and durability, making these PCBs a reliable choice for various high-performance applications. Copper Core PCBs, on the other hand, offer superior thermal conductivity compared to aluminum, making them ideal for applications that require even more efficient heat dissipation. Copper is an excellent conductor of heat, and its use in PCBs ensures that heat is quickly and effectively drawn away from critical components. This makes Copper Core PCBs suitable for high-power applications, such as power electronics and RF amplifiers, where managing heat is a significant challenge. However, copper is more expensive than aluminum, which can be a limiting factor for cost-sensitive applications. Despite the higher cost, the benefits of using copper in terms of thermal performance and reliability often outweigh the price considerations, especially in applications where performance is a priority. Alloys Core PCBs represent another category within the MCPCB market, offering a balance between the properties of aluminum and copper. These PCBs use a combination of metals to achieve desired thermal and mechanical characteristics. Alloys Core PCBs are designed to provide enhanced thermal management while maintaining cost-effectiveness. They are often used in applications where specific thermal and mechanical properties are required, such as in high-frequency circuits and power modules. The choice of alloy depends on the specific requirements of the application, with manufacturers offering a range of options to meet diverse needs. The development of new alloy materials and manufacturing techniques continues to expand the possibilities for Alloys Core PCBs, making them a versatile option for various industries. Overall, the choice between Aluminum Core, Copper Core, and Alloys Core PCBs depends on the specific requirements of the application, including thermal performance, cost, weight, and mechanical properties. Each type of MCPCB offers unique advantages, and the decision often involves a trade-off between these factors to achieve the best overall performance for the intended use.

LED Applications, Motion Control Applications, Solar Panels in the Global MCPCB Market:

The Global MCPCB Market finds extensive usage in LED applications, where efficient thermal management is crucial for maintaining the performance and longevity of the LEDs. MCPCBs are used as substrates for mounting LED chips, providing a platform that not only supports the electrical connections but also dissipates the heat generated by the LEDs. The metal core in MCPCBs acts as a heat sink, drawing heat away from the LEDs and spreading it evenly across the board. This helps in preventing hotspots, which can lead to premature failure of the LEDs. By maintaining a consistent operating temperature, MCPCBs ensure that the LEDs deliver optimal light output and color consistency over their lifespan. This is particularly important in high-power LED applications, such as street lighting, automotive lighting, and industrial lighting, where reliability and performance are critical. In motion control applications, MCPCBs are used to manage the heat generated by high-power components, such as motor drivers and power converters. These components are essential for controlling the speed and position of motors in various industrial and consumer applications. The efficient thermal management provided by MCPCBs helps in maintaining the performance and reliability of these components, ensuring smooth and precise motion control. The metal core in MCPCBs provides a stable platform for mounting components, reducing the risk of mechanical failure due to thermal expansion and contraction. This is particularly important in applications where precise control and reliability are essential, such as in robotics, CNC machines, and automotive systems. In solar panels, MCPCBs are used to manage the heat generated by power electronics, such as inverters and charge controllers. These components are responsible for converting the DC power generated by the solar panels into AC power for use in homes and businesses. The efficient thermal management provided by MCPCBs helps in maintaining the performance and reliability of these components, ensuring that the solar panels deliver optimal power output. The metal core in MCPCBs provides a stable platform for mounting components, reducing the risk of mechanical failure due to thermal expansion and contraction. This is particularly important in solar applications, where reliability and performance are critical for maximizing the return on investment. Overall, the Global MCPCB Market plays a vital role in supporting the development of high-performance, reliable electronic devices across multiple sectors, including LED applications, motion control applications, and solar panels. The efficient thermal management provided by MCPCBs helps in maintaining the performance and reliability of these devices, ensuring that they deliver optimal performance over their lifespan.

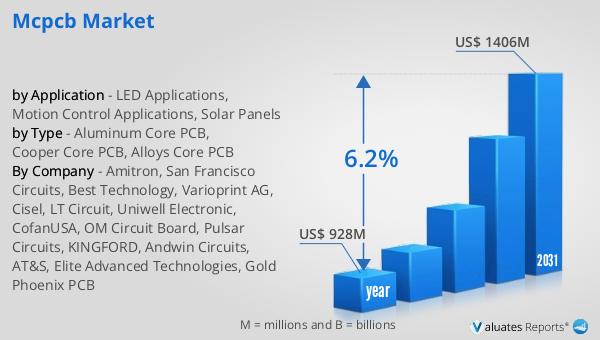

Global MCPCB Market Outlook:

In 2024, the global market for Metal Core Printed Circuit Boards (MCPCBs) was valued at approximately $928 million. Looking ahead, this market is anticipated to grow significantly, reaching an estimated size of $1,406 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.2% over the forecast period. The increasing demand for efficient thermal management solutions in high-performance electronic devices is a key driver of this growth. As electronic components become more complex and power-dense, the need for effective heat dissipation becomes increasingly critical. MCPCBs, with their metal cores, offer a reliable solution for managing heat in various applications, including LED lighting, power electronics, and automotive systems. The market is characterized by continuous innovation, with manufacturers focusing on developing advanced materials and designs to meet the evolving needs of end-users. The growing adoption of MCPCBs across various industries, including consumer electronics, automotive, telecommunications, and renewable energy, is expected to drive further growth in the market. Overall, the Global MCPCB Market is poised for significant expansion, supported by the increasing demand for high-performance, reliable electronic devices across multiple sectors.

| Report Metric | Details |

| Report Name | MCPCB Market |

| Accounted market size in year | US$ 928 million |

| Forecasted market size in 2031 | US$ 1406 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Amitron, San Francisco Circuits, Best Technology, Varioprint AG, Cisel, LT Circuit, Uniwell Electronic, CofanUSA, OM Circuit Board, Pulsar Circuits, KINGFORD, Andwin Circuits, AT&S, Elite Advanced Technologies, Gold Phoenix PCB |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |