What is Global Alumina (Al2O3) Powder for Ceramic Substrates Market?

Global Alumina (Al2O3) Powder for Ceramic Substrates Market is a specialized segment within the broader materials market, focusing on the production and application of alumina powder specifically for ceramic substrates. Alumina, or aluminum oxide (Al2O3), is a white crystalline powder known for its exceptional hardness, thermal stability, and electrical insulation properties. These characteristics make it an ideal material for ceramic substrates, which are used in various high-tech applications, including electronics, automotive, and aerospace industries. The market for alumina powder in this context is driven by the increasing demand for advanced ceramics that can withstand high temperatures and harsh environments while maintaining structural integrity and performance. As industries continue to push the boundaries of technology, the need for reliable and efficient materials like alumina powder becomes more pronounced, fueling growth in this market. The global alumina powder market for ceramic substrates is characterized by ongoing research and development efforts aimed at enhancing the material's properties and expanding its applications, ensuring its relevance in an ever-evolving technological landscape.

96% Al2O3 Powder, 99.6% Al2O3 Powder in the Global Alumina (Al2O3) Powder for Ceramic Substrates Market:

In the realm of Global Alumina (Al2O3) Powder for Ceramic Substrates Market, two significant types of alumina powder are 96% Al2O3 Powder and 99.6% Al2O3 Powder. These variations denote the purity levels of the alumina powder, which directly influence their applications and performance characteristics. The 96% Al2O3 Powder is a widely used variant due to its balance between cost-effectiveness and performance. It is commonly employed in applications where high thermal conductivity and electrical insulation are required, such as in electronic substrates and insulators. The slightly lower purity level compared to its 99.6% counterpart makes it more affordable, making it a popular choice for industries that require large volumes of material without compromising on essential properties. On the other hand, the 99.6% Al2O3 Powder represents a higher purity level, offering superior performance in terms of thermal and electrical properties. This variant is often used in high-end applications where maximum efficiency and reliability are critical, such as in aerospace components, high-frequency electronics, and advanced medical devices. The higher purity ensures minimal impurities, which can affect the material's performance, making it ideal for precision applications. The choice between 96% and 99.6% Al2O3 Powder depends largely on the specific requirements of the application, including factors such as operating environment, performance expectations, and budget constraints. As industries continue to innovate and demand more from their materials, the role of these alumina powders becomes increasingly important. Manufacturers are continually exploring ways to enhance the properties of these powders, such as improving their thermal conductivity, mechanical strength, and resistance to wear and corrosion. This ongoing development ensures that both 96% and 99.6% Al2O3 Powders remain at the forefront of material solutions for ceramic substrates. The market for these powders is also influenced by global trends such as the push for miniaturization in electronics, the need for more efficient energy systems, and the growing emphasis on sustainability. As a result, the demand for high-performance materials like alumina powder is expected to rise, driving further innovation and growth in this market segment. The interplay between cost, performance, and application requirements will continue to shape the landscape of the Global Alumina (Al2O3) Powder for Ceramic Substrates Market, ensuring its relevance and importance in the years to come.

DBC AlN Ceramic Substrates, DPC AlN Ceramic Substrates, Thin/Thick AlN Ceramic Substrates in the Global Alumina (Al2O3) Powder for Ceramic Substrates Market:

The usage of Global Alumina (Al2O3) Powder for Ceramic Substrates Market spans several critical areas, including DBC AlN Ceramic Substrates, DPC AlN Ceramic Substrates, and Thin/Thick AlN Ceramic Substrates. Each of these applications leverages the unique properties of alumina powder to meet specific performance criteria. DBC (Direct Bonded Copper) AlN Ceramic Substrates utilize alumina powder to provide a robust and thermally conductive base for electronic components. The high thermal conductivity of alumina ensures efficient heat dissipation, which is crucial for maintaining the performance and longevity of electronic devices. This makes DBC AlN substrates ideal for power electronics, LED lighting, and automotive applications where heat management is a critical concern. DPC (Direct Plated Copper) AlN Ceramic Substrates, on the other hand, benefit from the electrical insulation properties of alumina powder. These substrates are used in applications that require precise electrical performance, such as RF modules, microwave circuits, and high-frequency communication devices. The alumina powder ensures that the substrates can withstand high voltages and frequencies without compromising on performance. Thin/Thick AlN Ceramic Substrates also rely on alumina powder for their structural and thermal properties. These substrates are used in a variety of applications, including sensors, actuators, and other electronic components that require a combination of strength, thermal stability, and electrical insulation. The versatility of alumina powder allows these substrates to be tailored to specific application needs, ensuring optimal performance across a wide range of industries. The use of alumina powder in these applications highlights its importance as a material that can meet the demanding requirements of modern technology. As industries continue to evolve and demand more from their materials, the role of alumina powder in ceramic substrates is expected to grow, driving further innovation and development in this market.

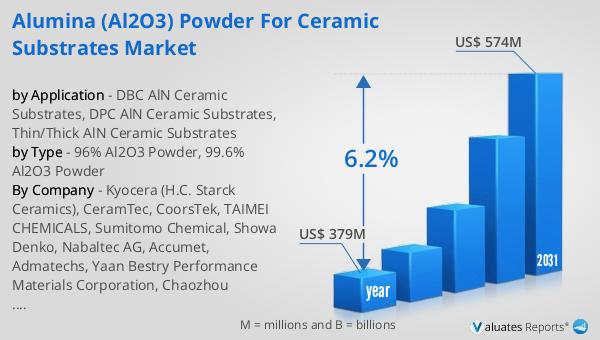

Global Alumina (Al2O3) Powder for Ceramic Substrates Market Outlook:

The global market for Alumina (Al2O3) Powder for Ceramic Substrates is experiencing significant growth, with its value estimated at $379 million in 2024. This market is projected to expand to a revised size of $574 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.2% over the forecast period. This growth is driven by the increasing demand for high-performance materials in various industries, including electronics, automotive, and aerospace. The unique properties of alumina powder, such as its thermal stability, electrical insulation, and mechanical strength, make it an ideal material for ceramic substrates used in these applications. As technology continues to advance, the need for reliable and efficient materials becomes more pronounced, fueling the demand for alumina powder. The market's expansion is also supported by ongoing research and development efforts aimed at enhancing the properties of alumina powder and expanding its applications. This ensures that the material remains relevant and competitive in an ever-evolving technological landscape. The projected growth of the global alumina powder market for ceramic substrates underscores the importance of this material in meeting the demands of modern technology and industry.

| Report Metric | Details |

| Report Name | Alumina (Al2O3) Powder for Ceramic Substrates Market |

| Accounted market size in year | US$ 379 million |

| Forecasted market size in 2031 | US$ 574 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kyocera (H.C. Starck Ceramics), CeramTec, CoorsTek, TAIMEI CHEMICALS, Sumitomo Chemical, Showa Denko, Nabaltec AG, Accumet, Admatechs, Yaan Bestry Performance Materials Corporation, Chaozhou Three-Circle (Group) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |