What is Global Inline Density Sensors Market?

The Global Inline Density Sensors Market refers to the industry focused on the production and distribution of sensors that measure the density of fluids in real-time as they flow through a pipeline or system. These sensors are crucial in various industries, including oil and gas, food and beverage, and chemical processing, where precise density measurements are essential for quality control, process optimization, and safety. Inline density sensors work by using different technologies such as vibrating element sensors, ultrasonic sensors, and Coriolis meters to provide accurate and continuous density readings. This market is driven by the increasing demand for automation and efficiency in industrial processes, as well as the need for real-time data to make informed decisions. As industries continue to evolve and prioritize precision and efficiency, the demand for inline density sensors is expected to grow, making it a vital component of modern industrial operations. The market is characterized by technological advancements, with manufacturers focusing on developing more accurate, reliable, and cost-effective sensors to meet the diverse needs of their clients. Overall, the Global Inline Density Sensors Market plays a crucial role in enhancing the operational efficiency and productivity of various industries worldwide.

Contact Type, Non-contact Type in the Global Inline Density Sensors Market:

In the Global Inline Density Sensors Market, sensors are broadly categorized into two types: contact type and non-contact type. Contact type sensors are designed to physically interact with the fluid whose density is being measured. These sensors are typically inserted directly into the fluid stream, allowing them to provide highly accurate and reliable measurements. The direct contact with the fluid enables these sensors to detect even the slightest changes in density, making them ideal for applications where precision is paramount. However, the contact nature of these sensors means they are more susceptible to wear and tear, and may require regular maintenance to ensure optimal performance. They are commonly used in industries where the fluid properties are stable and the risk of contamination is minimal, such as in certain chemical processing applications. On the other hand, non-contact type sensors measure fluid density without direct interaction with the fluid. These sensors use advanced technologies such as ultrasonic waves, microwave, or laser to determine the density of the fluid from a distance. The primary advantage of non-contact sensors is that they eliminate the risk of contamination and reduce maintenance requirements, as there is no physical contact with the fluid. This makes them particularly suitable for applications where hygiene is critical, such as in the food and beverage industry. Additionally, non-contact sensors are ideal for measuring the density of corrosive or hazardous fluids, as they can operate without being exposed to the potentially damaging effects of the fluid. Despite their advantages, non-contact sensors may be less accurate than their contact counterparts, especially in environments with high levels of interference or where the fluid properties are highly variable. Both contact and non-contact type sensors have their unique advantages and limitations, and the choice between the two often depends on the specific requirements of the application. For instance, in industries where precision and accuracy are critical, such as in pharmaceutical manufacturing, contact type sensors may be preferred. Conversely, in industries where hygiene and safety are paramount, such as in food processing, non-contact sensors may be more suitable. The decision to use either type of sensor also depends on factors such as cost, ease of installation, and maintenance requirements. As technology continues to advance, manufacturers are developing innovative solutions that combine the benefits of both contact and non-contact sensors, offering enhanced performance and versatility. This ongoing innovation is expected to drive the growth of the Global Inline Density Sensors Market, as industries seek more efficient and reliable ways to measure fluid density in real-time.

Industrial, Commercial in the Global Inline Density Sensors Market:

The usage of Global Inline Density Sensors Market in industrial and commercial areas is vast and varied, reflecting the diverse needs of these sectors. In industrial settings, inline density sensors are indispensable tools for monitoring and controlling processes in real-time. They are extensively used in the oil and gas industry to measure the density of crude oil, natural gas, and other hydrocarbons. Accurate density measurements are crucial for optimizing extraction processes, ensuring product quality, and complying with regulatory standards. In the chemical industry, these sensors help in maintaining the consistency and quality of chemical products by providing precise density data that is essential for process control and optimization. The food and beverage industry also relies heavily on inline density sensors to ensure product quality and consistency. These sensors are used to monitor the density of liquids such as juices, sauces, and dairy products, helping manufacturers maintain the desired product specifications and meet consumer expectations. In commercial applications, inline density sensors play a vital role in ensuring the quality and safety of products. For instance, in the pharmaceutical industry, these sensors are used to measure the density of liquid medications and other pharmaceutical products. Accurate density measurements are essential for ensuring the correct dosage and efficacy of medications, as well as for maintaining compliance with stringent regulatory standards. In the automotive industry, inline density sensors are used to monitor the density of fuels and lubricants, helping manufacturers optimize engine performance and reduce emissions. The sensors are also used in the production of paints and coatings, where precise density measurements are crucial for achieving the desired product characteristics and performance. The versatility and reliability of inline density sensors make them an invaluable asset in both industrial and commercial settings. Their ability to provide real-time, accurate density measurements enables businesses to optimize their processes, improve product quality, and reduce costs. As industries continue to evolve and prioritize efficiency and sustainability, the demand for inline density sensors is expected to grow. Manufacturers are continually developing new technologies and solutions to meet the changing needs of their customers, ensuring that inline density sensors remain at the forefront of industrial and commercial innovation. Overall, the Global Inline Density Sensors Market plays a crucial role in enhancing the operational efficiency and competitiveness of businesses across a wide range of industries.

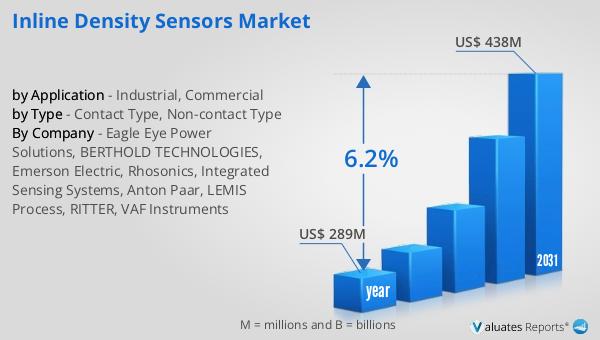

Global Inline Density Sensors Market Outlook:

The global market for Inline Density Sensors was valued at $289 million in 2024, and it is anticipated to expand to a revised size of $438 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.2% during the forecast period. This growth trajectory underscores the increasing demand for inline density sensors across various industries, driven by the need for precise and real-time density measurements. As industries continue to prioritize automation and efficiency, the adoption of inline density sensors is expected to rise, contributing to the market's expansion. The projected growth also highlights the ongoing advancements in sensor technology, with manufacturers focusing on developing more accurate, reliable, and cost-effective solutions to meet the diverse needs of their clients. The market's growth is further supported by the increasing emphasis on quality control and process optimization in industrial operations, as well as the growing demand for real-time data to make informed decisions. As a result, the Global Inline Density Sensors Market is poised for significant growth, offering numerous opportunities for manufacturers and stakeholders to capitalize on the increasing demand for these essential sensors.

| Report Metric | Details |

| Report Name | Inline Density Sensors Market |

| Accounted market size in year | US$ 289 million |

| Forecasted market size in 2031 | US$ 438 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Eagle Eye Power Solutions, BERTHOLD TECHNOLOGIES, Emerson Electric, Rhosonics, Integrated Sensing Systems, Anton Paar, LEMIS Process, RITTER, VAF Instruments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |