What is Global Automatic Helium Leak Detectors Market?

The Global Automatic Helium Leak Detectors Market is a specialized segment within the broader leak detection industry, focusing on devices that utilize helium as a tracer gas to identify leaks in various systems and components. Helium is preferred due to its small atomic size and inert nature, making it an ideal candidate for detecting even the smallest leaks with high precision. These detectors are crucial in industries where maintaining airtight systems is essential, such as in aerospace, automotive, and electronics manufacturing. The market for these detectors is driven by the increasing demand for high-quality, leak-proof products and the stringent regulations in place to ensure safety and reliability. As industries continue to innovate and develop more complex systems, the need for precise leak detection becomes even more critical, thereby fueling the growth of the automatic helium leak detectors market. The market is characterized by technological advancements, with manufacturers focusing on enhancing the sensitivity, accuracy, and user-friendliness of these devices. Additionally, the integration of digital technologies and automation in leak detection processes is expected to further propel the market's expansion. Overall, the Global Automatic Helium Leak Detectors Market plays a vital role in ensuring the integrity and safety of various industrial applications.

Mobile Type, Stationary Type in the Global Automatic Helium Leak Detectors Market:

In the Global Automatic Helium Leak Detectors Market, devices are broadly categorized into two types: Mobile Type and Stationary Type. Mobile Type helium leak detectors are designed for portability and ease of use in various locations. These devices are typically compact and lightweight, allowing technicians to carry them to different sites as needed. They are ideal for field applications where flexibility and mobility are crucial, such as in maintenance and repair operations in remote or hard-to-reach areas. Mobile detectors often come with features like battery operation, wireless connectivity, and rugged designs to withstand challenging environments. They are particularly useful in industries like automotive and aerospace, where components may need to be tested in different locations or during different stages of assembly. On the other hand, Stationary Type helium leak detectors are designed for fixed installations, often integrated into production lines or testing facilities. These detectors are typically larger and more robust, offering higher sensitivity and throughput compared to their mobile counterparts. Stationary detectors are ideal for high-volume testing and are commonly used in manufacturing environments where components need to be tested continuously or in large batches. They are often equipped with advanced features like automated testing sequences, data logging, and integration with other quality control systems. In industries such as electronics and semiconductor manufacturing, where precision and reliability are paramount, stationary helium leak detectors play a critical role in ensuring product quality and compliance with industry standards. Both Mobile and Stationary Type detectors have their unique advantages and are chosen based on the specific needs and constraints of the application. While mobile detectors offer flexibility and convenience, stationary detectors provide higher accuracy and efficiency for large-scale testing. As the demand for leak detection continues to grow across various industries, both types of detectors are expected to see increased adoption, driven by advancements in technology and the need for more efficient and reliable testing solutions. The choice between mobile and stationary detectors often depends on factors such as the size and complexity of the system being tested, the required sensitivity and accuracy, and the operational environment. Manufacturers in the Global Automatic Helium Leak Detectors Market are continually innovating to enhance the capabilities of both mobile and stationary detectors, incorporating features like digital interfaces, automated calibration, and remote monitoring to meet the evolving needs of their customers. As industries continue to prioritize safety, quality, and efficiency, the demand for both types of helium leak detectors is expected to remain strong, supporting the overall growth of the market.

Chemical Plant, Laboratory, Hospital, Others in the Global Automatic Helium Leak Detectors Market:

The Global Automatic Helium Leak Detectors Market finds extensive usage across various sectors, including Chemical Plants, Laboratories, Hospitals, and other industries. In chemical plants, helium leak detectors are essential for ensuring the integrity of pipelines, storage tanks, and other critical infrastructure. These facilities often handle hazardous materials, making leak detection crucial for preventing accidents and ensuring environmental safety. Helium leak detectors help identify even the smallest leaks, allowing for timely repairs and maintenance, thereby minimizing the risk of costly downtime and potential hazards. In laboratories, helium leak detectors are used to maintain the integrity of vacuum systems, gas chromatography equipment, and other sensitive instruments. Accurate leak detection is vital in research and development settings, where even minor leaks can compromise experimental results and lead to inaccurate data. Helium's inert nature and small atomic size make it an ideal tracer gas for detecting leaks in laboratory environments, ensuring the reliability and accuracy of scientific experiments. In hospitals, helium leak detectors play a critical role in maintaining the safety and functionality of medical equipment, such as MRI machines and gas delivery systems. Ensuring that these systems are leak-free is essential for patient safety and the effective operation of medical devices. Helium leak detectors help healthcare facilities comply with stringent safety standards and regulations, ensuring that medical equipment operates reliably and efficiently. Beyond these specific applications, helium leak detectors are also used in a variety of other industries, including automotive, aerospace, and electronics manufacturing. In the automotive industry, for example, helium leak detectors are used to test the integrity of fuel systems, air conditioning units, and other components to ensure vehicle safety and performance. In aerospace, these detectors are used to verify the integrity of critical components, such as fuel tanks and hydraulic systems, where even minor leaks can have significant consequences. In electronics manufacturing, helium leak detectors help ensure the quality and reliability of products by detecting leaks in components like semiconductors and microchips. Overall, the Global Automatic Helium Leak Detectors Market plays a vital role in ensuring the safety, reliability, and efficiency of various industrial applications. As industries continue to prioritize quality and safety, the demand for helium leak detectors is expected to grow, driven by the need for precise and reliable leak detection solutions.

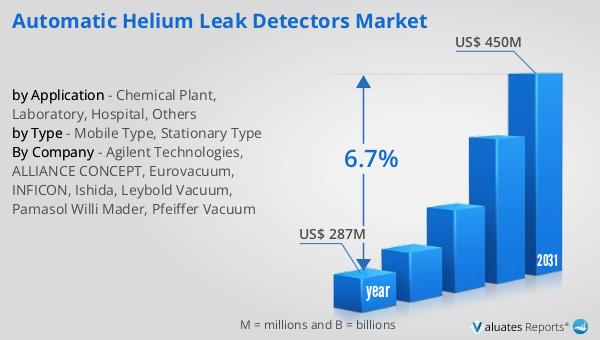

Global Automatic Helium Leak Detectors Market Outlook:

The global market for Automatic Helium Leak Detectors was valued at $287 million in 2024, with projections indicating a growth to $450 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.7% over the forecast period. This upward trajectory highlights the increasing demand for helium leak detectors across various industries, driven by the need for high-quality, leak-proof products and stringent safety regulations. The market's expansion is supported by technological advancements, with manufacturers focusing on enhancing the sensitivity, accuracy, and user-friendliness of these devices. The integration of digital technologies and automation in leak detection processes is also expected to contribute to the market's growth. As industries continue to innovate and develop more complex systems, the need for precise leak detection becomes even more critical, further fueling the demand for automatic helium leak detectors. The market's growth is also influenced by the increasing adoption of helium leak detectors in emerging economies, where industrialization and infrastructure development are driving the demand for reliable and efficient leak detection solutions. Overall, the Global Automatic Helium Leak Detectors Market is poised for significant growth, driven by the increasing demand for high-quality, leak-proof products and the need for precise and reliable leak detection solutions.

| Report Metric | Details |

| Report Name | Automatic Helium Leak Detectors Market |

| Accounted market size in year | US$ 287 million |

| Forecasted market size in 2031 | US$ 450 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Agilent Technologies, ALLIANCE CONCEPT, Eurovacuum, INFICON, Ishida, Leybold Vacuum, Pamasol Willi Mader, Pfeiffer Vacuum |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |