What is Global Bare Aluminum Nitride (AlN) Ceramic Substrates Market?

The Global Bare Aluminum Nitride (AlN) Ceramic Substrates Market is a specialized segment within the broader ceramics industry, focusing on the production and application of aluminum nitride substrates. These substrates are known for their excellent thermal conductivity, electrical insulation properties, and mechanical strength, making them ideal for high-performance electronic applications. The market is driven by the increasing demand for efficient thermal management solutions in electronics, particularly in sectors like telecommunications, automotive, and consumer electronics. As electronic devices become more compact and powerful, the need for materials that can effectively dissipate heat without compromising electrical performance becomes critical. AlN ceramic substrates offer a solution to this challenge, providing a reliable platform for mounting electronic components. The market is characterized by a mix of established players and emerging companies, all striving to innovate and improve the performance of AlN substrates. With advancements in manufacturing technologies and growing applications in various industries, the Global Bare Aluminum Nitride Ceramic Substrates Market is poised for significant growth in the coming years. The market's expansion is also supported by the increasing adoption of electric vehicles and renewable energy systems, which require efficient thermal management solutions.

AlN-170, AlN-200, Others in the Global Bare Aluminum Nitride (AlN) Ceramic Substrates Market:

AlN-170 and AlN-200 are specific grades of aluminum nitride ceramic substrates that cater to different performance requirements in the Global Bare Aluminum Nitride (AlN) Ceramic Substrates Market. AlN-170 is typically characterized by its moderate thermal conductivity and is often used in applications where cost-effectiveness is a priority without significantly compromising on performance. This grade is suitable for general-purpose applications where the thermal management requirements are not extremely demanding. On the other hand, AlN-200 offers higher thermal conductivity, making it ideal for more demanding applications that require efficient heat dissipation. This grade is often used in high-power electronic devices, where managing heat is crucial to maintaining performance and reliability. The choice between AlN-170 and AlN-200 depends on the specific requirements of the application, including factors like thermal management needs, cost considerations, and the operating environment. In addition to these two grades, there are other variations of AlN ceramic substrates available in the market, each designed to meet specific performance criteria. These variations may include differences in thickness, surface finish, and mechanical properties, allowing manufacturers to tailor the substrates to the unique needs of their applications. The development of these different grades and variations is driven by ongoing research and innovation in materials science, as well as the evolving demands of the electronics industry. As technology continues to advance, the need for more efficient and reliable thermal management solutions will likely drive further innovation in the AlN ceramic substrates market. This innovation is crucial for supporting the development of next-generation electronic devices, which are expected to be more powerful and compact than ever before. The ability to effectively manage heat in these devices will be a key factor in their success, making AlN ceramic substrates an essential component in the electronics industry.

IGBT Module, LED, Optical Communication, Aerospace, Others in the Global Bare Aluminum Nitride (AlN) Ceramic Substrates Market:

The Global Bare Aluminum Nitride (AlN) Ceramic Substrates Market finds extensive usage across various industries, including IGBT modules, LED technology, optical communication, aerospace, and others. In IGBT modules, which are critical components in power electronics, AlN ceramic substrates are used for their excellent thermal conductivity and electrical insulation properties. These substrates help in efficiently dissipating heat generated by the IGBT modules, ensuring their reliable operation and longevity. The ability to manage heat effectively is crucial in power electronics, where excessive heat can lead to device failure. In the LED industry, AlN ceramic substrates are used to enhance the thermal management of LED chips, improving their performance and lifespan. LEDs generate a significant amount of heat during operation, and efficient heat dissipation is essential to maintain their brightness and color consistency. AlN substrates provide a reliable solution for managing this heat, enabling the development of high-performance LED lighting solutions. In optical communication, AlN ceramic substrates are used in the packaging of optical components, where their thermal and electrical properties help maintain signal integrity and performance. The aerospace industry also benefits from the use of AlN ceramic substrates, particularly in applications where high thermal conductivity and mechanical strength are required. These substrates are used in various aerospace components, including sensors and electronic control systems, where they help manage heat and ensure reliable operation in demanding environments. Beyond these specific applications, AlN ceramic substrates are also used in other industries, such as automotive and telecommunications, where efficient thermal management is critical. The versatility and performance of AlN ceramic substrates make them an essential component in a wide range of electronic applications, supporting the development of advanced technologies across multiple industries. As the demand for more efficient and reliable electronic devices continues to grow, the usage of AlN ceramic substrates is expected to expand further, driving innovation and development in the market.

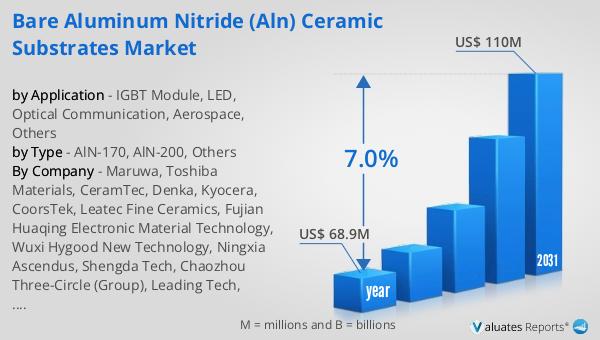

Global Bare Aluminum Nitride (AlN) Ceramic Substrates Market Outlook:

The outlook for the Global Bare Aluminum Nitride (AlN) Ceramic Substrates Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 68.9 million, and it is anticipated to reach a revised size of US$ 110 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.0% over the forecast period. This growth is driven by the increasing demand for efficient thermal management solutions in various industries, including electronics, automotive, and telecommunications. The market is dominated by a leading company that holds a significant share of over 35%, highlighting the competitive landscape and the importance of innovation and quality in maintaining market leadership. The Asia Pacific region emerges as the largest market for AlN ceramic substrates, accounting for about 77% of the global share. This dominance is attributed to the region's robust electronics manufacturing industry and the growing adoption of advanced technologies. Europe and North America follow, with shares of approximately 9% and 8%, respectively. These regions also contribute to the market's growth through ongoing research and development activities and the increasing demand for high-performance electronic devices. The market's expansion is further supported by the rising adoption of electric vehicles and renewable energy systems, which require efficient thermal management solutions. As the market continues to evolve, companies are focusing on developing innovative products and expanding their production capacities to meet the growing demand. The Global Bare Aluminum Nitride Ceramic Substrates Market is poised for significant growth, driven by technological advancements and the increasing need for efficient thermal management solutions in various industries.

| Report Metric | Details |

| Report Name | Bare Aluminum Nitride (AlN) Ceramic Substrates Market |

| Accounted market size in year | US$ 68.9 million |

| Forecasted market size in 2031 | US$ 110 million |

| CAGR | 7.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Maruwa, Toshiba Materials, CeramTec, Denka, Kyocera, CoorsTek, Leatec Fine Ceramics, Fujian Huaqing Electronic Material Technology, Wuxi Hygood New Technology, Ningxia Ascendus, Shengda Tech, Chaozhou Three-Circle (Group), Leading Tech, Zhejiang Zhengtian New Materials, Hexagold Electronic Technology, Fujian ZINGIN New Material Technology, Shandong Sinocera Functional Material, Weihai Yuanhuan Advanced Ceramics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |