What is Global Robotic Machine Sensor Market?

The Global Robotic Machine Sensor Market is a rapidly evolving sector that plays a crucial role in the advancement of robotics technology. These sensors are integral components that enable robots to interact with their environment in a more intelligent and efficient manner. By providing robots with the ability to perceive their surroundings, these sensors enhance the functionality and versatility of robotic systems across various industries. The market encompasses a wide range of sensor types, each designed to perform specific functions such as detecting movement, interpreting visual data, sensing touch, and recognizing voice commands. As industries increasingly adopt automation to improve productivity and reduce operational costs, the demand for sophisticated robotic machine sensors continues to grow. This market is characterized by continuous innovation, with companies investing heavily in research and development to create sensors that are more accurate, reliable, and capable of operating in diverse environments. The global reach of this market is evident as it caters to a multitude of sectors including automotive, aerospace, electronics, and more, each benefiting from the enhanced capabilities that these sensors provide. As technology advances, the Global Robotic Machine Sensor Market is expected to expand further, offering new opportunities and challenges for businesses and consumers alike.

Movement Sensor, Vision Sensor, Touch Sensor, Voice Sensor, Others in the Global Robotic Machine Sensor Market:

Movement sensors are a fundamental component of the Global Robotic Machine Sensor Market, providing robots with the ability to detect and respond to motion within their environment. These sensors are crucial for navigation and obstacle avoidance, allowing robots to move efficiently and safely in dynamic settings. They work by detecting changes in position or speed, enabling robots to adjust their movements accordingly. Vision sensors, on the other hand, equip robots with the capability to interpret visual information. These sensors use cameras and image processing algorithms to analyze the environment, identify objects, and make decisions based on visual data. This is particularly useful in applications such as quality inspection, where robots need to identify defects or inconsistencies in products. Touch sensors, also known as tactile sensors, allow robots to perceive physical interactions with objects. These sensors mimic the human sense of touch, enabling robots to handle delicate items with precision and care. They are essential in applications where robots need to manipulate objects without causing damage. Voice sensors add another layer of interaction by allowing robots to recognize and respond to verbal commands. This capability is increasingly important in service robotics, where human-robot interaction is a key component. Other types of sensors in the market include temperature sensors, which help robots monitor and adapt to environmental conditions, and proximity sensors, which detect the presence of nearby objects without physical contact. Each of these sensors plays a vital role in enhancing the capabilities of robotic systems, making them more adaptable and efficient in performing complex tasks. As the demand for automation continues to rise, the development and integration of these sensors will be pivotal in driving the growth of the Global Robotic Machine Sensor Market.

Automotive, Machinery, Aerospace, Electronics Automotive, Others in the Global Robotic Machine Sensor Market:

The usage of the Global Robotic Machine Sensor Market spans across various industries, each leveraging the unique capabilities of these sensors to enhance their operations. In the automotive industry, robotic sensors are used extensively in manufacturing processes such as assembly, painting, and quality control. Movement sensors enable robots to navigate production lines with precision, while vision sensors ensure that each component is correctly positioned and assembled. Touch sensors allow robots to handle parts delicately, reducing the risk of damage during assembly. In the machinery sector, robotic sensors are employed to improve the efficiency and accuracy of machine operations. They enable machines to perform tasks such as welding, cutting, and drilling with high precision, reducing waste and increasing productivity. The aerospace industry also benefits from robotic sensors, particularly in the manufacturing and maintenance of aircraft. Vision sensors are used for inspecting aircraft components, ensuring they meet stringent safety standards. Touch sensors assist in the delicate handling of sensitive parts, while movement sensors facilitate the precise positioning of components during assembly. In the electronics industry, robotic sensors play a crucial role in the production of electronic devices. They enable robots to perform tasks such as soldering and component placement with high accuracy, ensuring the quality and reliability of the final product. Other industries, such as healthcare and logistics, also utilize robotic sensors to improve efficiency and accuracy in their operations. In healthcare, for example, robotic sensors are used in surgical robots to enhance precision and control during procedures. In logistics, sensors enable robots to navigate warehouses and handle packages efficiently. Overall, the Global Robotic Machine Sensor Market provides essential tools that help industries optimize their processes, reduce costs, and improve product quality.

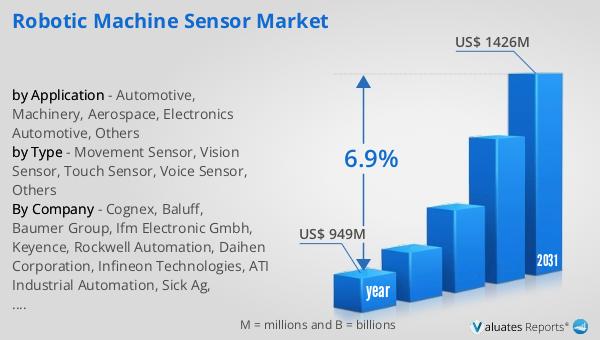

Global Robotic Machine Sensor Market Outlook:

The global market for Robotic Machine Sensors was valued at approximately $949 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $1,426 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.9% over the forecast period. This upward trend is indicative of the increasing demand for advanced robotic technologies across various industries. As businesses strive to enhance operational efficiency and reduce costs, the adoption of robotic systems equipped with sophisticated sensors is becoming more prevalent. These sensors are crucial for enabling robots to perform complex tasks with precision and reliability, making them indispensable in sectors such as automotive, aerospace, electronics, and more. The projected growth of the market reflects the ongoing advancements in sensor technology, as well as the expanding applications of robotics in diverse fields. Companies are investing heavily in research and development to create sensors that are more accurate, durable, and capable of functioning in challenging environments. As a result, the Global Robotic Machine Sensor Market is poised for substantial growth, offering new opportunities for innovation and expansion. This market outlook underscores the importance of robotic sensors in driving the future of automation and highlights the potential for continued growth and development in this dynamic field.

| Report Metric | Details |

| Report Name | Robotic Machine Sensor Market |

| Accounted market size in year | US$ 949 million |

| Forecasted market size in 2031 | US$ 1426 million |

| CAGR | 6.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Cognex, Baluff, Baumer Group, Ifm Electronic Gmbh, Keyence, Rockwell Automation, Daihen Corporation, Infineon Technologies, ATI Industrial Automation, Sick Ag, Honeywell, Datalogic, Texas Instruments, TDK, Sensopart |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |