What is Global High Capacity Petroleum Sorbent Pad Market?

The Global High Capacity Petroleum Sorbent Pad Market is a specialized segment within the broader environmental protection and spill management industry. These sorbent pads are designed to absorb large quantities of petroleum-based liquids, making them essential tools in managing oil spills and leaks. They are particularly valuable in industries where oil and petroleum products are frequently used or transported, such as oil and gas, manufacturing, and chemical sectors. The market for these high-capacity sorbent pads is driven by the increasing awareness of environmental protection and the stringent regulations imposed by governments worldwide to prevent and manage oil spills. These pads are made from materials that can absorb oil while repelling water, which makes them highly efficient in dealing with oil spills on both land and water surfaces. The demand for these products is expected to grow as industries continue to prioritize environmental safety and compliance with regulatory standards. The market is characterized by a variety of products that differ in terms of absorption capacity, material composition, and application suitability, catering to diverse industrial needs. As industries strive to minimize their environmental footprint, the role of high-capacity petroleum sorbent pads becomes increasingly significant.

Synthetic Polypropylene Fiber Thread, Non-woven Fabric Material, Graphene-wrapped Sponge in the Global High Capacity Petroleum Sorbent Pad Market:

In the Global High Capacity Petroleum Sorbent Pad Market, several materials are utilized to enhance the efficiency and effectiveness of these pads. One of the primary materials used is Synthetic Polypropylene Fiber Thread. This material is favored for its high absorbency and durability, making it ideal for creating sorbent pads that can withstand harsh industrial environments. Polypropylene fibers are hydrophobic, meaning they repel water while absorbing oil, which is crucial for effective oil spill management. These fibers are woven into a fabric that forms the base of many sorbent pads, providing a strong and reliable structure that can handle large volumes of oil. Another important material in this market is Non-woven Fabric Material. Non-woven fabrics are created by bonding fibers together through chemical, mechanical, or thermal processes, rather than weaving or knitting. This results in a fabric that is highly absorbent and can be produced at a lower cost compared to woven fabrics. Non-woven fabrics are lightweight and flexible, allowing them to conform to various surfaces and shapes, which is particularly useful in spill response scenarios where the terrain may be uneven or challenging. The versatility and cost-effectiveness of non-woven fabrics make them a popular choice in the production of high-capacity petroleum sorbent pads. Graphene-wrapped Sponge is an innovative material that has recently gained attention in the Global High Capacity Petroleum Sorbent Pad Market. Graphene is a form of carbon known for its exceptional strength and conductivity. When used in sorbent pads, graphene can significantly enhance the absorption capacity and speed of oil uptake. The sponge structure, wrapped in graphene, provides a large surface area for oil absorption, making it highly efficient in dealing with large spills. Additionally, graphene-wrapped sponges are reusable, which offers a sustainable solution for oil spill management. After absorbing oil, these sponges can be cleaned and reused multiple times, reducing waste and lowering the overall cost of spill response operations. The combination of these materials in the production of high-capacity petroleum sorbent pads ensures that they are effective, durable, and adaptable to various industrial needs. Each material brings unique properties that enhance the overall performance of the sorbent pads, making them indispensable tools in the fight against oil pollution. As industries continue to seek more efficient and sustainable solutions for spill management, the development and use of advanced materials like Synthetic Polypropylene Fiber Thread, Non-woven Fabric Material, and Graphene-wrapped Sponge will play a crucial role in shaping the future of the Global High Capacity Petroleum Sorbent Pad Market.

Oil and Gas, Manufacturing, Chemical, Others in the Global High Capacity Petroleum Sorbent Pad Market:

The Global High Capacity Petroleum Sorbent Pad Market finds extensive usage across various industries, each with its unique requirements and challenges. In the Oil and Gas sector, these sorbent pads are critical for managing spills that occur during drilling, extraction, transportation, and refining processes. The industry is prone to accidental leaks and spills, which can have devastating environmental impacts if not managed promptly and effectively. High-capacity sorbent pads are used to quickly absorb and contain oil spills, preventing them from spreading and causing further damage. Their ability to absorb large quantities of oil makes them an essential tool in the oil and gas industry's spill response toolkit. In the Manufacturing sector, petroleum sorbent pads are used to manage oil leaks and spills that occur during machinery operation and maintenance. Manufacturing facilities often use oil and lubricants to keep machines running smoothly, and leaks can occur due to equipment failure or human error. Sorbent pads are placed strategically around machinery to catch any leaks, ensuring that the work environment remains safe and clean. This not only helps in maintaining operational efficiency but also ensures compliance with environmental regulations that mandate the proper management of oil spills. The Chemical industry also relies heavily on high-capacity petroleum sorbent pads to manage spills of oil-based chemicals and solvents. Chemical plants often handle large volumes of hazardous materials, and spills can pose significant risks to both the environment and human health. Sorbent pads are used to quickly contain and absorb spills, minimizing the risk of contamination and exposure. The use of these pads is an integral part of the industry's safety protocols, helping to prevent accidents and ensure a safe working environment. Beyond these specific industries, high-capacity petroleum sorbent pads are used in various other sectors, including transportation, marine, and environmental services. In the transportation sector, they are used to manage spills that occur during the loading and unloading of oil and petroleum products. In marine environments, sorbent pads are used to clean up oil spills in water bodies, protecting marine life and ecosystems. Environmental service companies use these pads in their spill response operations, providing cleanup services to industries and municipalities. Overall, the versatility and effectiveness of high-capacity petroleum sorbent pads make them indispensable tools in managing oil spills across a wide range of industries. Their ability to quickly absorb and contain oil helps prevent environmental damage and ensures compliance with regulatory standards, making them a critical component of any spill response strategy.

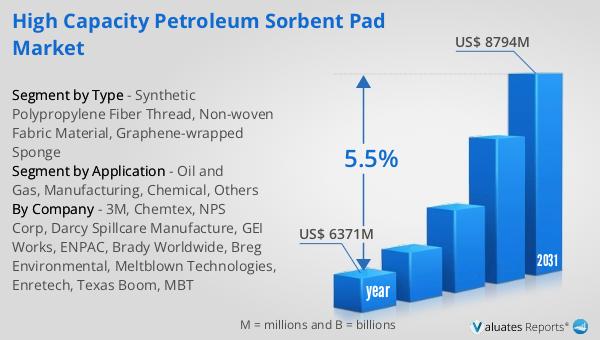

Global High Capacity Petroleum Sorbent Pad Market Outlook:

The global market for High Capacity Petroleum Sorbent Pads was valued at approximately $6,371 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $8,794 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.5% over the forecast period. The increasing demand for effective spill management solutions across various industries is a key driver of this market growth. As industries such as oil and gas, manufacturing, and chemicals continue to prioritize environmental safety and regulatory compliance, the need for high-capacity sorbent pads is expected to rise. These pads offer an efficient and reliable solution for managing oil spills, helping industries minimize their environmental impact and adhere to stringent regulations. The market's growth is also supported by advancements in material technology, which have led to the development of more effective and sustainable sorbent pads. As the market continues to evolve, it is likely to see further innovations that enhance the performance and sustainability of these products, ensuring their continued relevance and demand in the global market.

| Report Metric | Details |

| Report Name | High Capacity Petroleum Sorbent Pad Market |

| Accounted market size in year | US$ 6371 million |

| Forecasted market size in 2031 | US$ 8794 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, Chemtex, NPS Corp, Darcy Spillcare Manufacture, GEI Works, ENPAC, Brady Worldwide, Breg Environmental, Meltblown Technologies, Enretech, Texas Boom, MBT |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |